Preparation method of aromatic polybenzimidazole

A polybenzimidazole and aromatic technology, applied in the field of polymer resin preparation, can solve problems such as processing difficulties, and achieve the effects of good thermal stability, high molecular weight, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

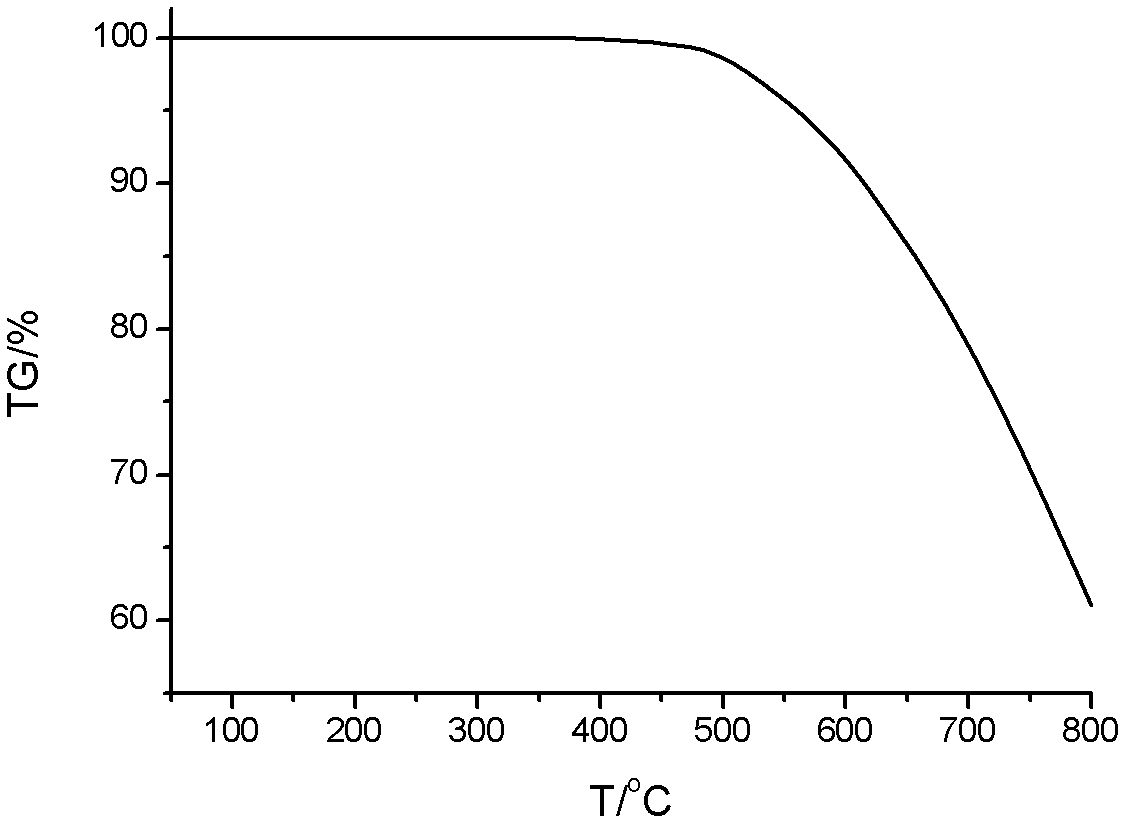

Embodiment 1

[0031] Add 680g of phosphorus pentoxide into 5000ml of methanesulfonic acid, heat up to 140°C, blow nitrogen and start stirring until the phosphorus pentoxide is completely dissolved. Add 214g of 3,3',4,4'-tetraaminobiphenyl and 202g of sebacic acid and stir for 1h to obtain a viscous liquid. Pour the above viscous liquid into water to precipitate the polymer, and then wash the polymer repeatedly for more than three times; then, soak it in 10% sodium bicarbonate for 48 hours and take it out; after that, soak it in boiling water containing sodium hydrosulfite; In this embodiment, the hydrosulfite is a kind of sodium thiosulfate; for example: after washing the precipitated polymer repeatedly, soak it with 10% sodium bicarbonate for 48 hours, take it out, and then soak it in a solution containing 0.5% thiosulfuric acid Sodium boiling aqueous solution for 5 hours, take out the polymer; then put it in a vacuum environment of 60-80 ℃ and dry for 24 hours to obtain polybenzimidazole ...

Embodiment 2

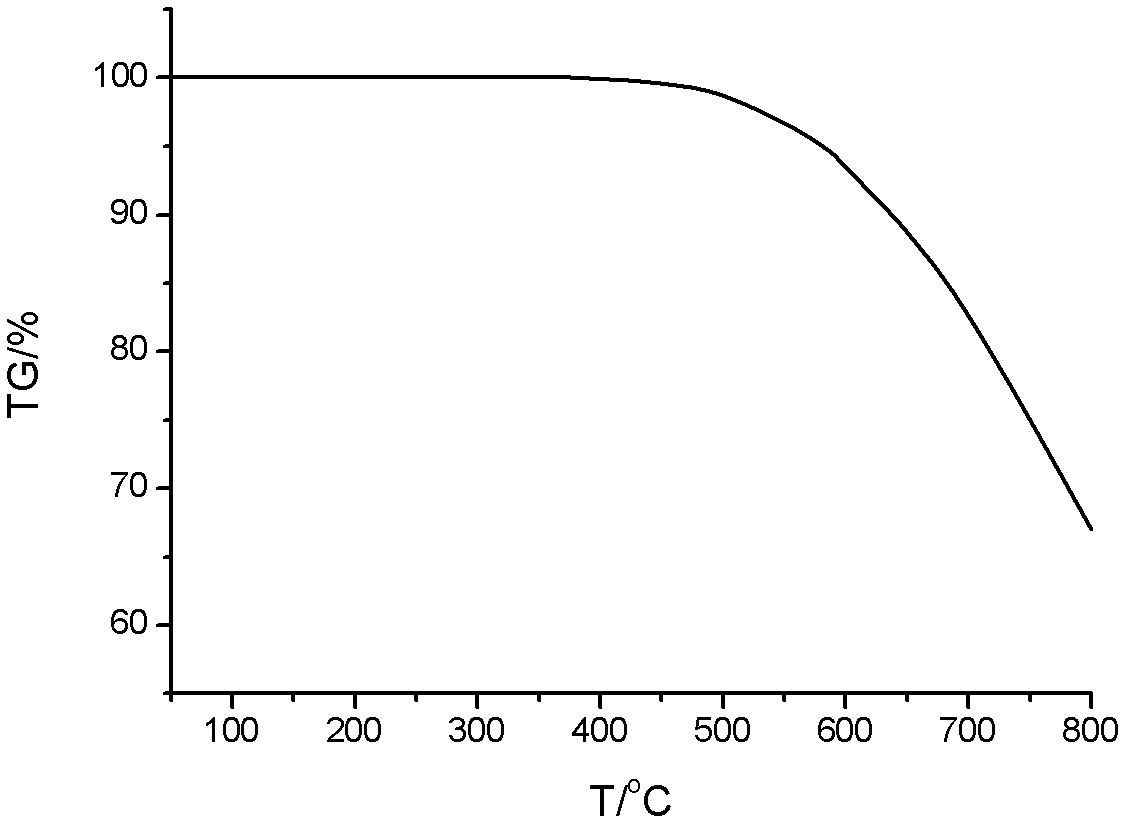

[0033] Add 680g of phosphorus pentoxide to 5000ml of methanesulfonic acid, heat up to 100°C, blow nitrogen and start stirring until phosphorus pentoxide is completely dissolved, add 278g of 3,3',4,4'-tetraaminobiphenyl sulfone, 258g 4,4'-dicarboxydiphenyl ether was stirred and reacted for 20 minutes to obtain a viscous liquid. The above-mentioned viscous liquid is poured into water to precipitate a polymer, and the polymer is soaked in 15% sodium carbonate for 36 hours after repeated washing and taken out; after that, it is soaked in boiling water containing sodium hydrosulfite; in this embodiment, its insurance The powder is a kind of sodium dithionite; for example: after washing the precipitated polymer repeatedly with water, soak it in 15% sodium carbonate for 36 hours, take it out, then soak it in a boiling aqueous solution containing 2% sodium dithionite for 1 hour, take out the polymer and put it in Drying in a vacuum environment at 90-120° C. for 12 hours to obtain poly...

Embodiment 3

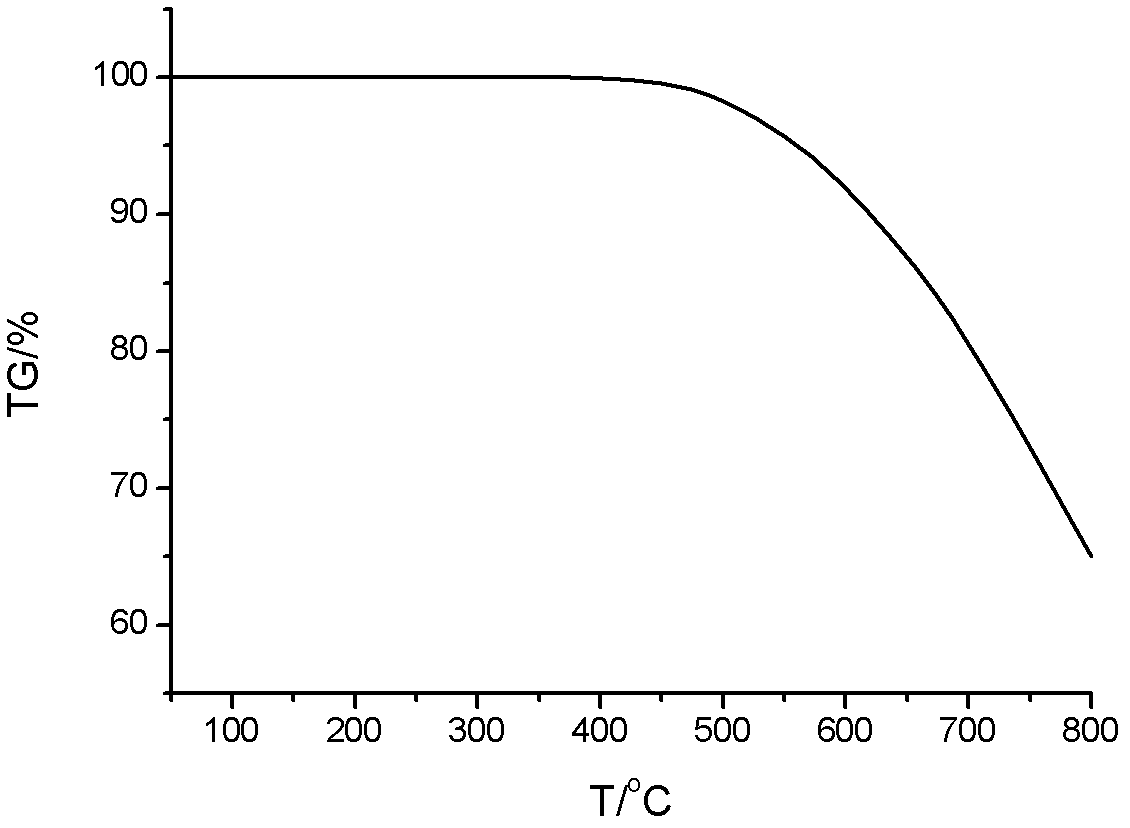

[0035] Add 1360g of phosphorus pentoxide into 10000ml of methanesulfonic acid, heat up to 130-150°C, blow nitrogen and start stirring until phosphorus pentoxide is completely dissolved, add 428g of 3,3',4,4'-tetraaminobiphenyl, 202g of sebacic acid and 258g of 4,4'-dicarboxydiphenyl ether were stirred and reacted for 30 minutes to obtain a viscous liquid. Pour the above-mentioned viscous liquid into water to precipitate a polymer, which is soaked in 10% sodium bicarbonate for 58 hours after repeated washing and then taken out; after that, soak in boiling water containing sodium hydrosulfite; in this embodiment, its Sodium hydrosulfite is a kind of sodium dithionite; for example: after washing the precipitated polymer repeatedly, soak it in 10% sodium bicarbonate for 58 hours, take it out, then soak it in a boiling water solution containing 3% sodium dithionite for 1 hour, take out the polymer The material was dried under a vacuum environment at 100-110° C. for 48 hours to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com