Polymer solar cell and manufacturing method of polymer solar cell

A technology of solar cells and polymers, applied in the field of solar cells, can solve the problems that the application of semiconductor oxide nanorod array structure has not been reported in relevant literature, and achieve the advantages of long-term stability of optoelectronic properties and the effect of improving photocurrent density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

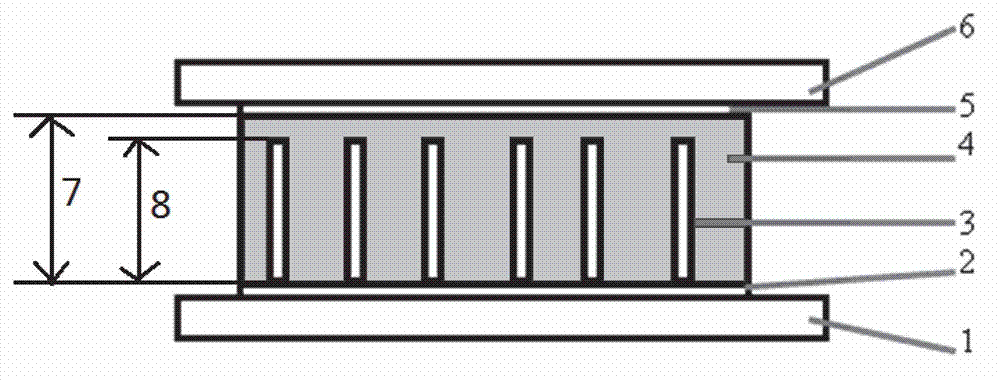

[0029] The preparation method of the novel structure polymer solar cell that the present invention proposes, comprises the following steps:

[0030] (1) Synthetic electron collection layer material:

[0031] Using solvothermal method, template method, electrodeposition method or anodic oxidation method, on a transparent conductive glass substrate covered with a layer of titanium dioxide, zinc oxide or tin oxide film in advance, grow a semiconductor oxide one-dimensional nano-array structure film;

[0032] (2) Spin coating active layer material:

[0033] The mixed solution of conjugated polymer materials and fullerene derivatives is spin-coated on the transparent conductive glass substrate with the electron collection layer material by spin coating method, so that the active layer material can be well filled in the gap of the nano-array film, and properly used The thickness of the active layer is 10-200nm higher than the length of the one-dimensional nano-array, and the solvent ...

Embodiment 1

[0044] Using the pyrolysis method, titanium tetrachloride was used as the titanium source, and a layer of titanium dioxide film was fabricated on the FTO glass substrate, and then the titanium dioxide nanorod array film was grown on the substrate by the hydrothermal method. The hydrothermal temperature was 150 °C, and the hydrothermal The time is 2 hours, the filling degree of the hydrothermal tank is 0.6, the hydrothermal precursor solution used is a mixed solution of 0.42g butyl titanate and 30ml solvent, and the solvent is deionized water and concentrated hydrochloric acid with a volume ratio of 1:1 mixed solution. The obtained nanorod array has a length of about 300 nm, a nanorod diameter of 40 nm, and a nanorod gap of about 100 nm. Spin-coat a chlorobenzene solution with a mass ratio of P3HT to PCBM of 1:1 and a sum of mass concentrations of 28 mg / ml by spin coating on an FTO glass substrate with a titanium dioxide nanorod array film, so that the active layer material is ...

Embodiment 2

[0047] Using the spin coating method, tetraisopropyl titanate is used as the titanium source, and a layer of titanium dioxide film is fabricated on the FTO glass substrate. After sintering, the titanium dioxide nanorod array film is grown on the substrate by the hydrothermal method, and the hydrothermal temperature is 150°C. , the hydrothermal time is 2 hours, the filling degree of the hydrothermal tank is 0.6, the hydrothermal precursor solution used is a mixed solution of 0.42g butyl titanate and 30ml solvent, and the solvent is deionized water with a volume ratio of 1:1 Mixed solution with concentrated hydrochloric acid. The obtained nanorod array has a length of about 300 nm, a nanorod diameter of 40 nm, and a nanorod gap of about 100 nm. Spin-coat a chlorobenzene solution with a mass ratio of P3HT to PCBM of 1:1 and a sum of mass concentrations of 28 mg / ml by spin coating on an FTO glass substrate with a titanium dioxide nanorod array film, so that the active layer materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com