Integrated technology of thermal decomposing, dry distilling and gasifying sludge and preparing of ceramsite

A technology of pyrolysis and dry distillation and ceramsite, which is applied in pyrolysis treatment of sludge, dehydration/drying/concentrated sludge treatment, clay products, etc., can solve the problems of soil and crops being polluted, achieve significant economic benefits, curb the secondary Effects of production of harmful substances such as oxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

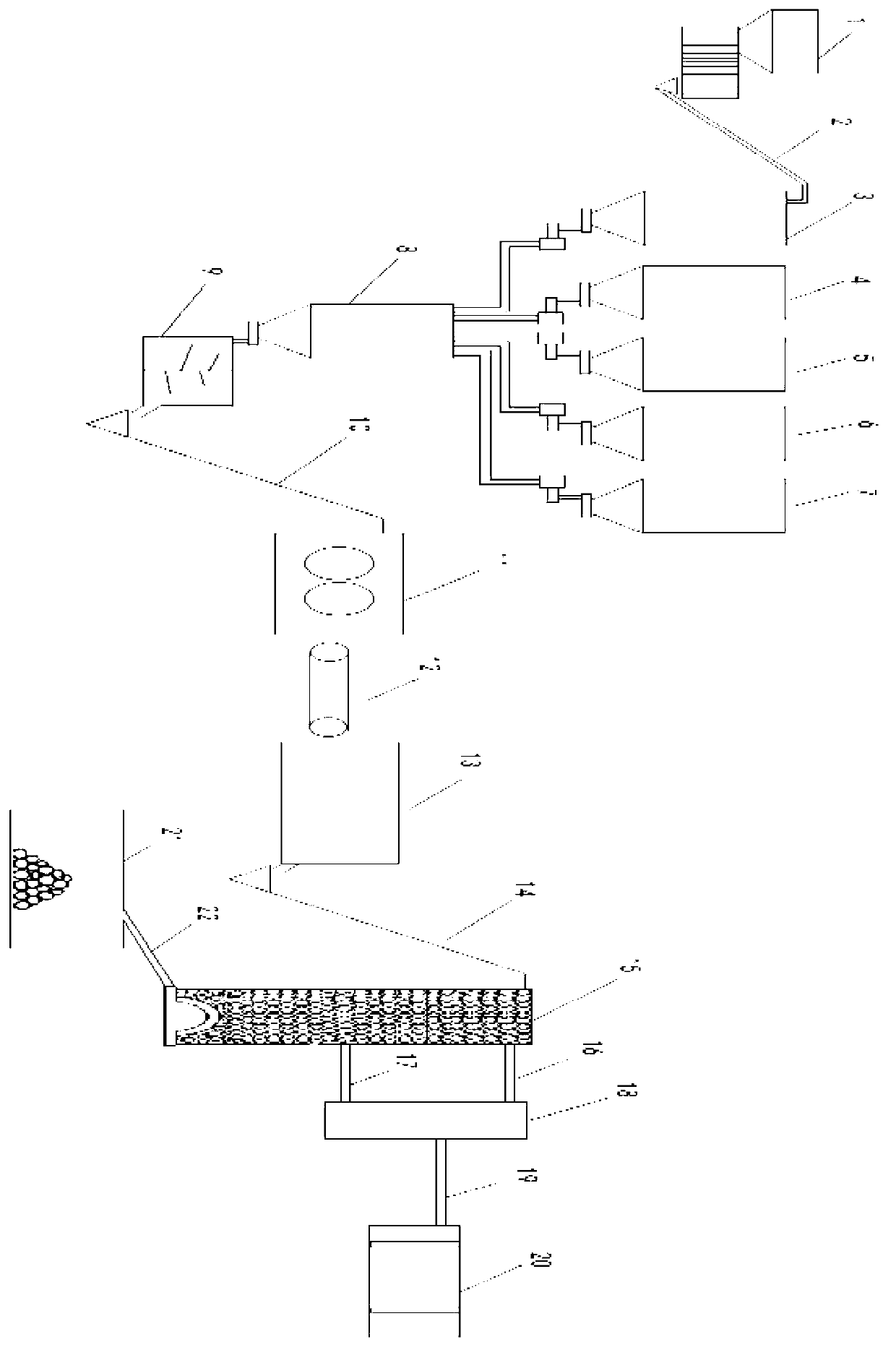

[0025] After the urban sludge with a moisture content of 80% to 90% is dehydrated through a plate filter press (1) to a moisture content of 50-60%, the dewatered sludge: coal powder: cement: fly ash: plant The mass ratio of fiber=68%: 14%: 6%: 10%: 2% is taken, and placed in storage bins (3), (4), (5), (6), (7) respectively; after that Transport it to the homogenization bin (8) for mixing, and then send it to the mixer (9) to mix evenly; then lift it to the extrusion pelletizer (11) through the elevator (10) to extrude the mixture to prepare granules Sludge pellets with a diameter of 10-20mm.

[0026] The sludge balls are sent to the drying kiln (13) through the transmission belt (12) and dried until the moisture content is 8-12%, and the drying temperature is 150-180°C; the dried sludge balls are then passed through the elevator (14 ) is transported to the pyrolysis dry distillation gasifier (15) for reaction.

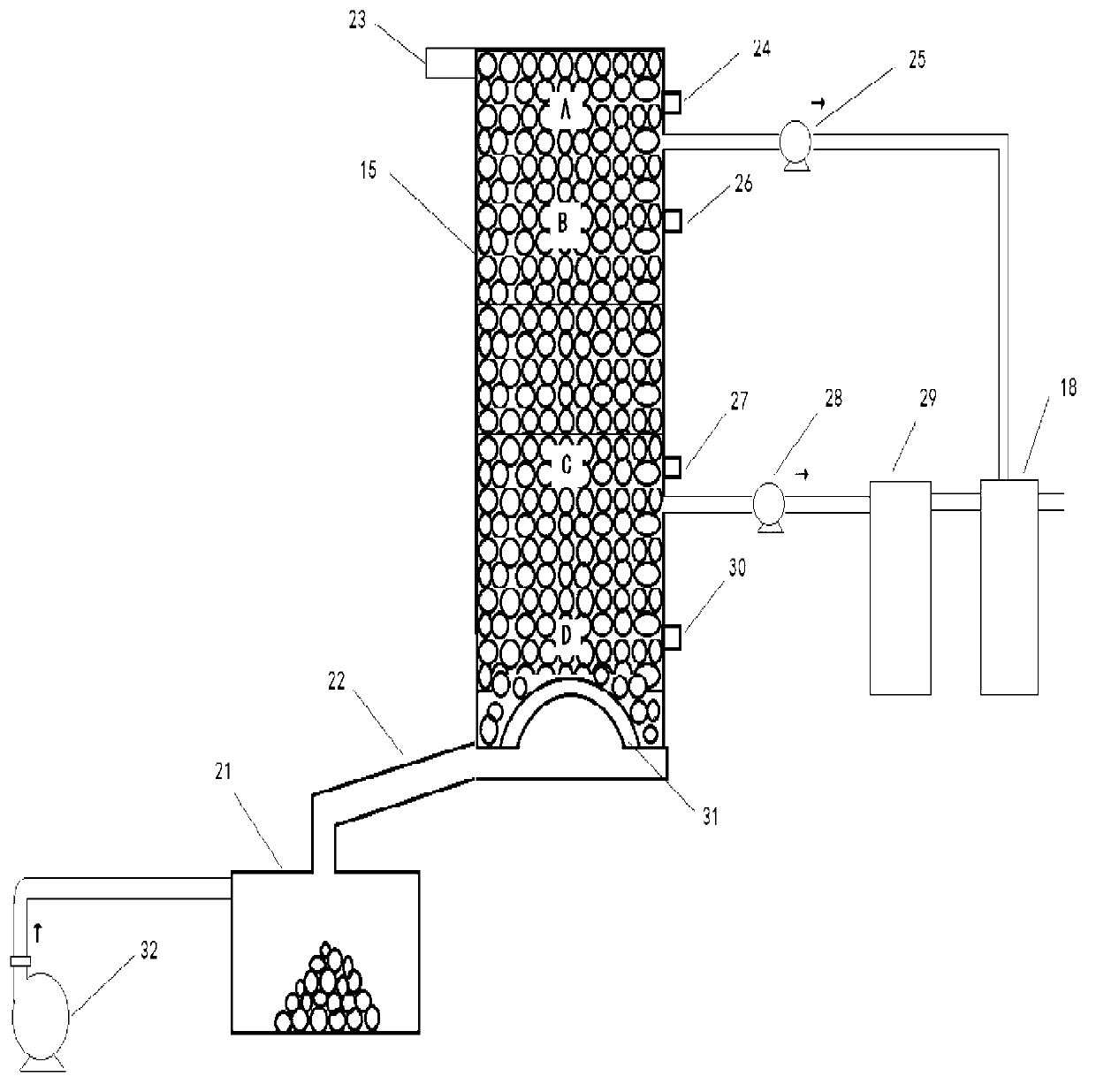

[0027] The inside of the pyrolysis dry distillation gasifier (...

Embodiment 2

[0033] After the urban sludge with a moisture content of 80% to 90% is dehydrated through a filter press to a moisture content of 50-60%, the dewatered sludge: coal powder: cement: fly ash: plant fiber = 80% : The mass ratio of 9%:4%:6%:1% is taken.

[0034] The rest are operated according to Example 1 to obtain light and high-strength ceramsite and recycle combustible gas C m h n 、H 2 and CO, etc.; the waste heat when the ceramsite is cooled is used as the heat when the sludge pellets are dried in the kiln.

Embodiment 3

[0036] After the urban sludge with a moisture content of 80% to 90% is dehydrated through a filter press to a moisture content of 50-60%, the dewatered sludge: coal powder: cement: fly ash: plant fiber = 88% : The mass ratio of 6%:2%:3%:1% is taken.

[0037] The rest are operated according to Example 1 to obtain light and high-strength ceramsite and recycle combustible gas C m h n 、H 2and CO, etc.; the waste heat when the ceramsite is cooled is used as the heat when the sludge pellets are dried in the kiln.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com