Water-based fireproof paint

A fire-resistant coating, water-based technology, applied in the direction of fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of loss, building casualties, economics, etc., and achieve low cost, beautiful and glossy film formation, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

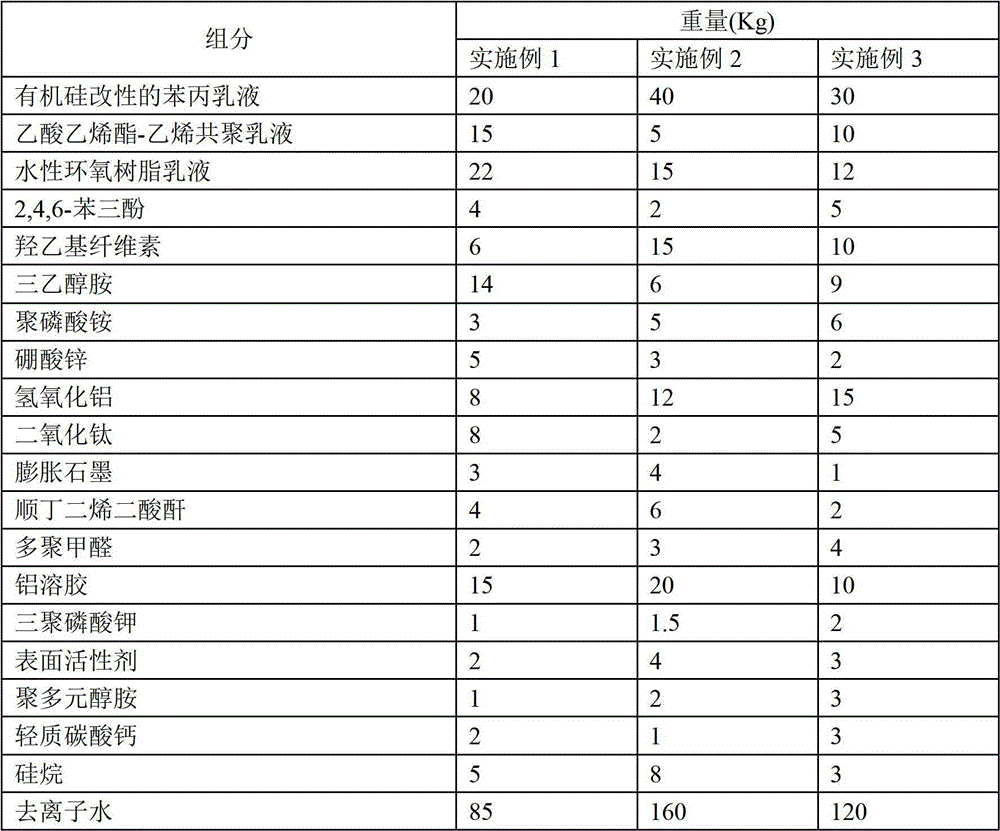

[0013] The weight proportion of table 1 embodiment 1~embodiment 3

[0014]

[0015] The concentration of the above-mentioned aluminum sol is 10%.

[0016] The above-mentioned silane adopts methyltriethoxysilane.

[0017] The preparation method of each embodiment is:

[0018] S1 Silicone-modified styrene-acrylic emulsion, vinyl acetate-ethylene copolymer emulsion, water-based epoxy resin emulsion, 2,4,6-glucinol, hydroxyethyl cellulose, triethanolamine, ammonium polyphosphate, zinc borate , aluminum hydroxide, titanium dioxide, expanded graphite, maleic anhydride, paraformaldehyde, surfactant and some deionized water are added to the stirring tank, and the components are stirred evenly at a stirring speed of 200r / min .

[0019] S2 Put the slurry obtained in S1 into a ball mill tank, and use alumina ceramic balls as the ball mill medium for ball milling, and the ball milling time is 2 to 4 hours.

[0020] S3 Add aluminum sol, potassium tripolyphosphate, polypolyolamine, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com