Dried lumbrukinase powder preparation method

A technology of lumbrokinase dry powder and earthworm, which is applied in the directions of biochemical equipment and methods, enzymes, hydrolase, etc., can solve the problems of low quality standard of lumbrokinase, frequent regeneration, high pressure on environmental protection, etc. Scale, the effect of improving work capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

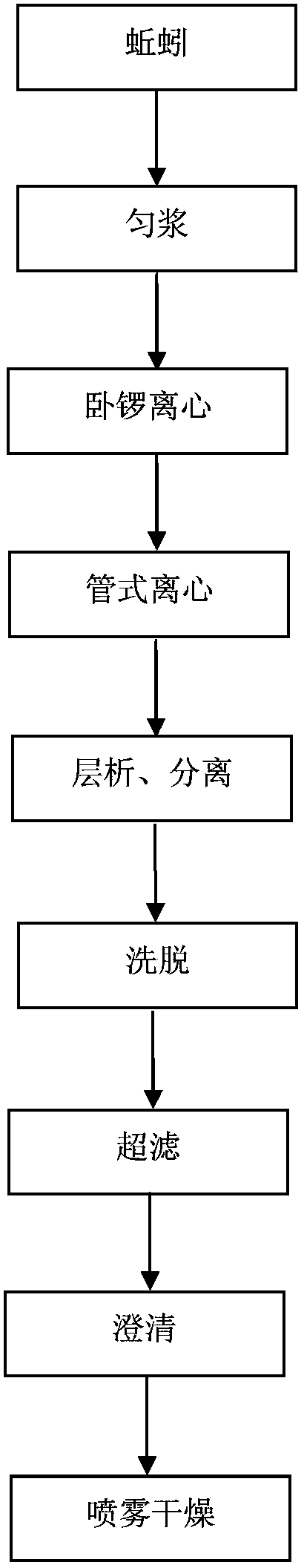

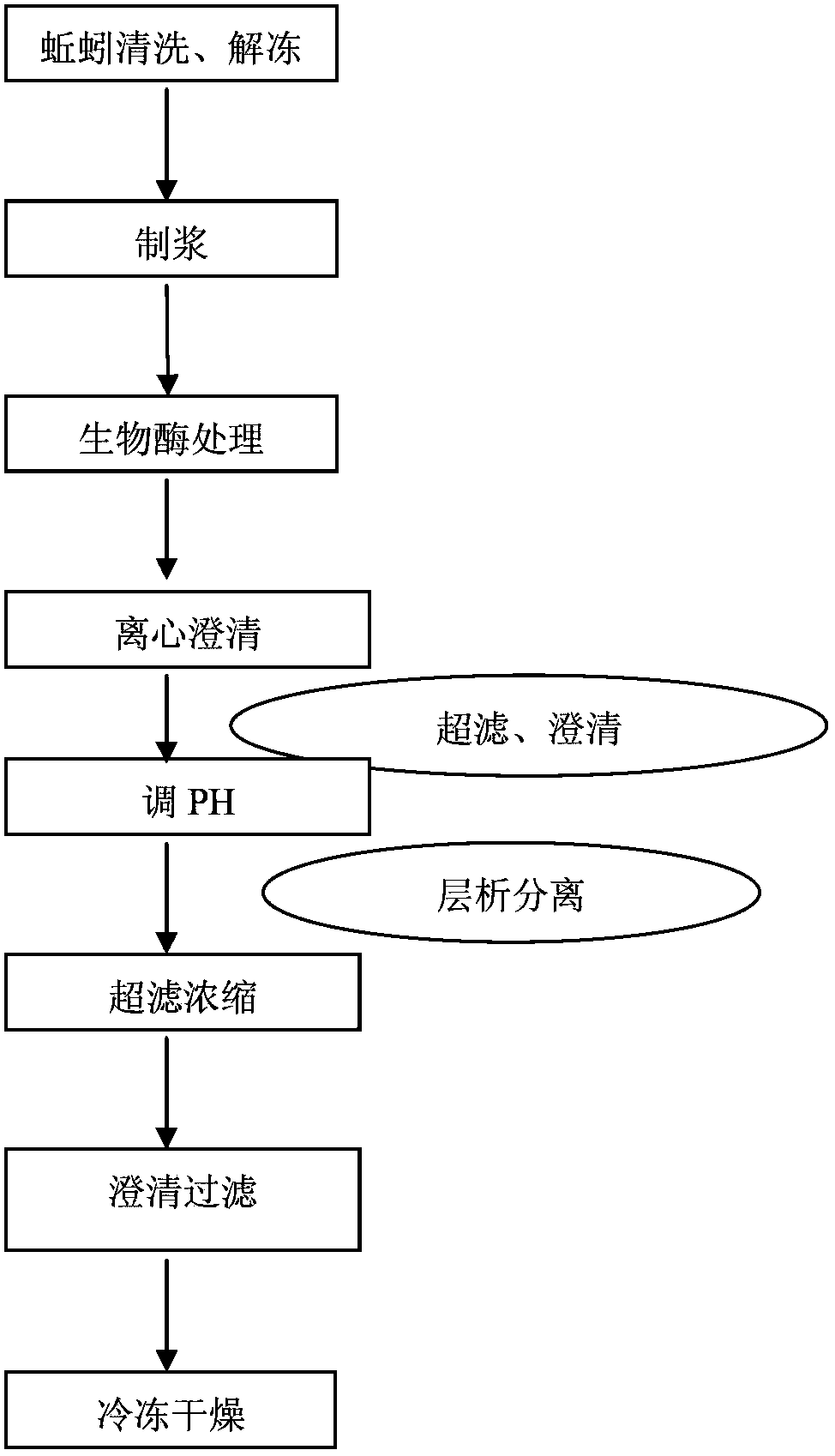

Method used

Image

Examples

Embodiment 1

[0034] 1) Cleaning and thawing of earthworms: wash fresh earthworms with water, wash away sludge and sticky matter, and then store them in a cold storage for later use; place 800kg of frozen earthworms at room temperature to thaw naturally;

[0035] 2) Pulp making: add water 1.0 times the volume of the earthworms in the homogenization tank, pour the completely thawed earthworms, crush the earthworms with a homogenizer, and homogenize for 2.0 hours to form a homogenate;

[0036] 3) Biological enzyme treatment: add serrapeptase in an amount of 0.1% of the weight of earthworms to the homogenate in step 2), control the temperature at 35°C, and keep the temperature for 6 hours;

[0037] 4) Centrifugation: the homogenate in step 3) is quantitatively diluted with water, and the final volume is set to 2.5 tons, and the coarse slag is removed by a butterfly centrifuge;

[0038] 5) clarification: after step 4) the centrifugate after slag removal is input into the membrane filtration sys...

Embodiment 2

[0047]1) Cleaning and thawing of earthworms: wash fresh earthworms with water, wash away sludge and sticky matter, and then store them in a cold storage for later use; place 800kg of frozen earthworms at room temperature to thaw naturally;

[0048] 2) Pulp making: add water 1.0 times the volume of the earthworms in the homogenization tank, pour the completely thawed earthworms, crush the earthworms with a homogenizer, and homogenize for 2.0 hours to form a homogenate;

[0049] 3) Biological enzyme treatment: in the homogenate in step 2), add bromelain in an amount of 0.1% of the weight of the earthworm, control it at 35° C., and keep it for 6 hours;

[0050] 4) Centrifugation: the homogenate in step 3) is quantitatively diluted with water, and the final volume is set to 2.5 tons, and the coarse slag is removed by a butterfly centrifuge;

[0051] 5) clarification: after step 4) the centrifugate after slag removal is input into the membrane filtration system, add water to wash, ...

Embodiment 3

[0060] 1) Cleaning and thawing of earthworms: wash fresh earthworms with water, wash away sludge and sticky matter, and then store them in a cold storage for later use; place 800kg of frozen earthworms at room temperature to thaw naturally;

[0061] 2) Pulp making: add water 1.0 times the volume of the earthworms in the homogenization tank, pour the completely thawed earthworms, crush the earthworms with a homogenizer, and homogenize for 2.0 hours to form a homogenate;

[0062] 3) Biological enzyme treatment: in the homogenate in step 2), add papain in an amount of 0.1% of the weight of earthworms, control at 35° C., and keep the temperature for 6 hours;

[0063] 4) Centrifugation: the homogenate in step 3) is quantitatively diluted with water, and the final volume is set to 2.5 tons, and the coarse slag is removed by a butterfly centrifuge;

[0064] 5) clarification: after step 4) the centrifugate after slag removal is input into the membrane filtration system, add water to w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com