Method of loading titanium dioxide nanorod arrays on surface of titanium wire mesh

A nanorod array, titanium dioxide technology, applied in nanotechnology, chemical instruments and methods, nanotechnology and other directions for materials and surface science, to achieve the effect of low cost, simple and easy method, and strong bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Mix hydrofluoric acid with a concentration of 55%, nitric acid with a concentration of 65% and deionized water in a volume ratio of 1:3:6 to obtain a pickling solution;

[0040] 2) Add 0.67 ml of 63% nitric acid and 66.7 mg of hexamethylenetetramine to 50 ml of 20% hydrogen peroxide solution to obtain a reaction solution;

[0041] 3) Set the size to 2.5×2.5×0.01 (cm 3 ) After the metal titanium wire mesh is pickled with the above mixed acid, it is cleaned with deionized water in ultrasonic waves. Then immersed in the reaction solution of step 2), reacted at 80°C for 60 h;

[0042] 4) After the reaction, the titanium screen was washed with deionized water, dried, and placed in 80°C hot water with a pH value of 1.0 adjusted with hydrochloric acid. After reacting for 72 h, it was taken out, washed with deionized water, and dried to obtain a surface-loaded Titanium mesh of titania nanorod arrays.

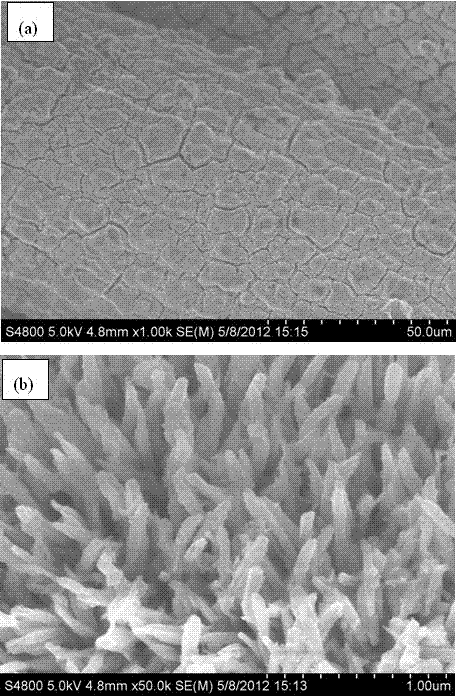

[0043] Response result

[0044] The surface of the titanium mesh is u...

Embodiment 2

[0046] 1) Same as step 1 of Example 1);

[0047] 2) Add 0.80 ml of 63% nitric acid and 75.0 mg of hexamethylenetetramine to 50 ml of 20% hydrogen peroxide solution to obtain a reaction solution;

[0048] 3) Same as Step 3 of Example 1);

[0049] 4) After the reaction, the titanium mesh was washed with deionized water, dried, and placed in hot water at 80°C with a pH value of 2.0 adjusted with hydrochloric acid. After reacting for 60 h, it was taken out, washed with deionized water, and dried to obtain a surface-loaded Titanium mesh of titania nanorod arrays.

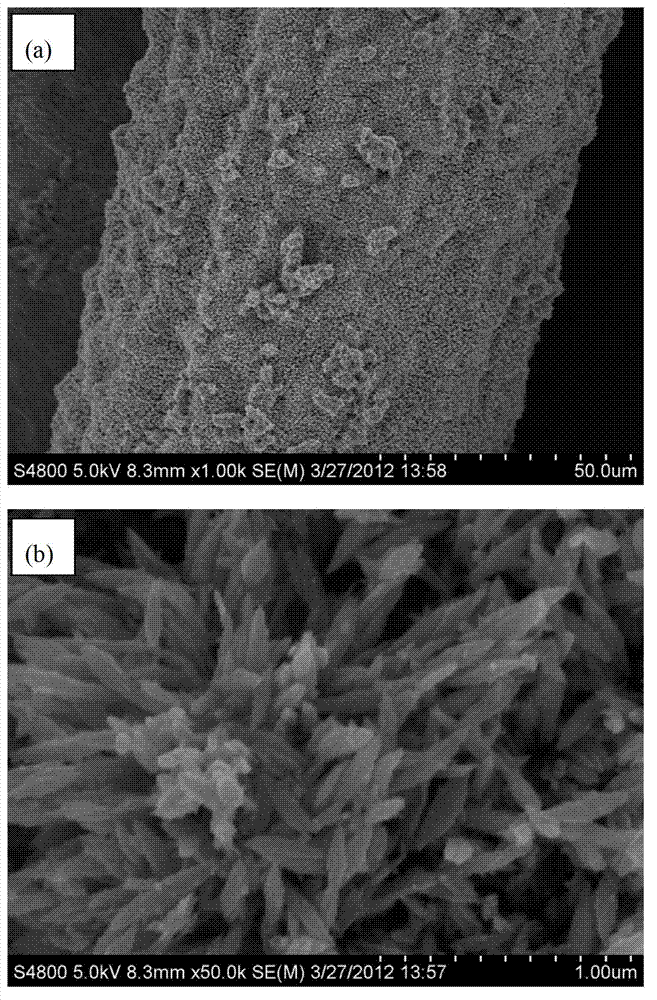

[0050] Response result

[0051] The surface of the titanium mesh is uniformly generated as figure 2 For the titania nanorod array shown, the nanorods have an average length of about 600 nm and an average diameter of 120 nm. The results of X-ray diffraction showed that the crystal structure of aligned titania nanorods supported on the surface of the titanium mesh was a mixed crystal phase of rutile and anatase (see ...

Embodiment 3

[0053] 1) Same as step 1 of Example 1);

[0054] 2) Same as Step 2 of Example 1);

[0055] 3) Same as Step 3 of Example 1);

[0056] 4) After the reaction, the titanium mesh was washed with deionized water, dried, and placed in hot water at 80°C with a pH value of 3.0 adjusted with hydrochloric acid. After reacting for 72 h, it was taken out, washed with deionized water, and dried to obtain a surface-loaded Titanium mesh of titania nanorod arrays.

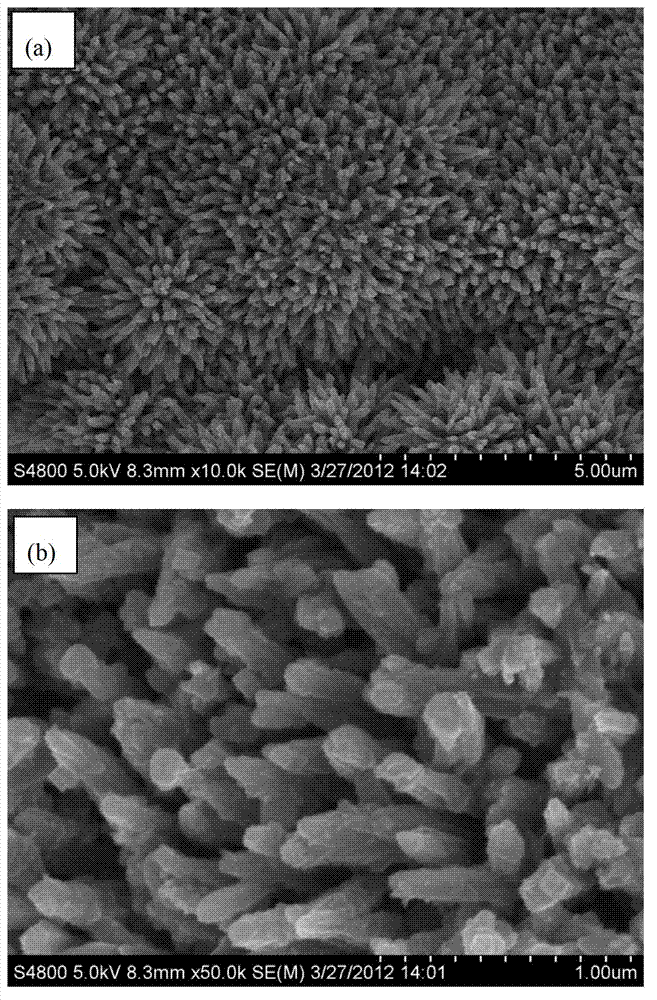

[0057] Response result

[0058] The surface of the titanium mesh is uniformly generated as Figure 4 TiO2 nanorod array shown, the average diameter of the nanorods is 120 nm. The crystal structure of the aligned titanium dioxide nanorods supported on the surface of the titanium mesh is a mixed crystal phase of rutile and anatase (see Figure 5 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com