Room temperature water-phase synthesis method for zeolite imidazole ester framework material

A technology of zeolite imidazolate and framework materials, applied in cobalt organic compounds, zinc organic compounds, etc., can solve the problems of solvents and by-products, high synthesis temperature, low reaction yield, etc., and achieve high reaction yield and good crystallinity , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Efficient preparation at room temperature of Example 1Zn framework material

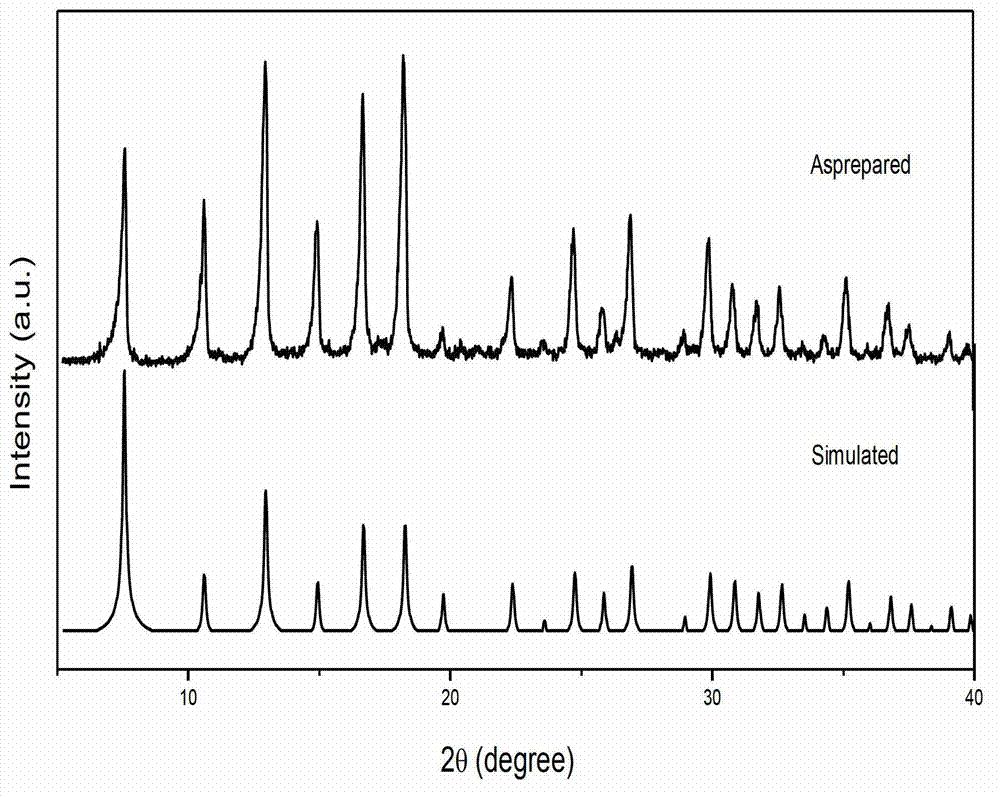

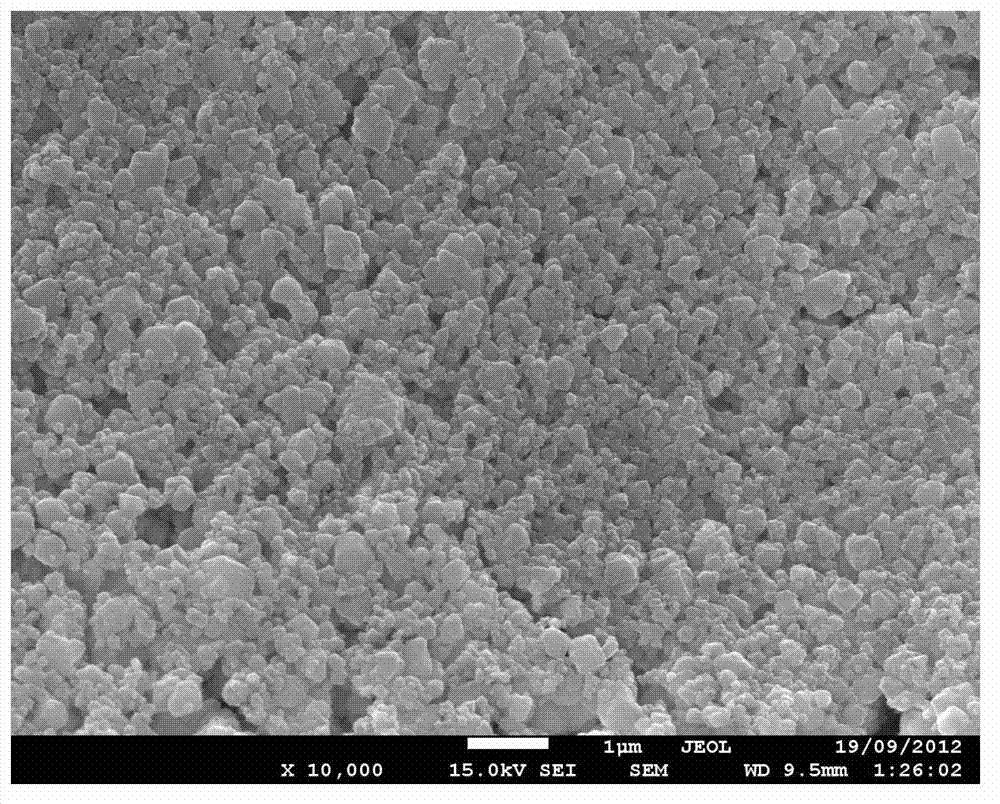

[0031] Into the 250mL beaker, add 1.362gZnCl 2 , 1.64g of 2-methylimidazole, add 100mL of water, 5g of 28%-30% ammonia solution, 0.1g of non-ionic surfactant L64 and 10mL of absolute ethanol solution and stir evenly for ten minutes, then filter and separate, dry at 80°C for 12hr, and get Metal imidazole coordination framework materials. Its X-ray diffraction pattern is shown in figure 1 , according to the comparison of literature (Science, 2008, 319, 939), it can be known that this material corresponds to the Zif-8 sodalite (sod) topology. its microscopic appearance figure 2 Scanning electron micrograph, for nano-sized particles. The nitrogen adsorption isotherm diagram is shown in image 3 , it can be known that it is a microporous material with a BET specific surface area of 1030m 2 / g, pore volume 0.51cm 3 / g.

Embodiment 2

[0032] Efficient preparation at room temperature of embodiment 2Zn framework material

[0033] In a suitable capacity beaker, add 21.9g Zn(Ac) 2 and 250mL of water, add 16.4g of 2-methylimidazole, 250mL of water, 50g of 28%-30% ammonia solution, 2.5g of nonionic surfactant F127 into another beaker, stir evenly for 20 minutes, filter and separate, and dry at 60°C After 24 hours, the metal imidazole coordination framework material was obtained. Its X-ray diffraction pattern is shown in image 3 , according to the comparison of literature (Science, 2008, 319, 939), it can be known that this material corresponds to the Zif-8 sodalite (sod) topology. its microscopic appearance Figure 4 Scanning electron micrograph, for nano-sized particles.

Embodiment 3

[0034] Efficient preparation at room temperature of embodiment 3Zn framework material

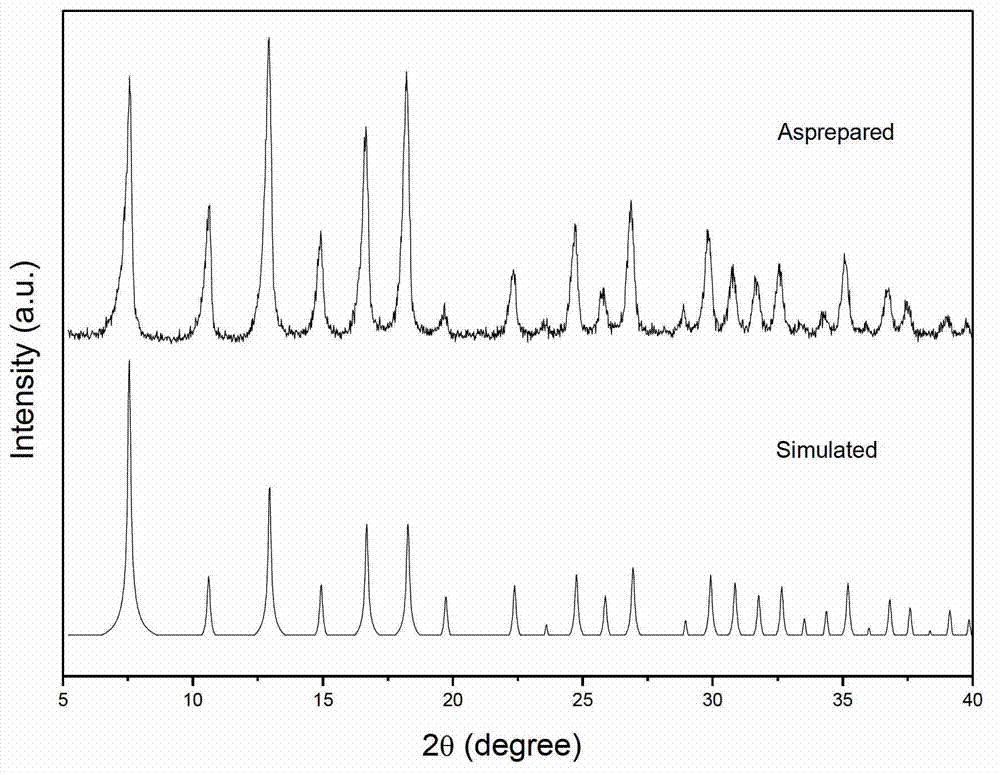

[0035] In a suitable capacity beaker, add 29.7g Zn(NO 3 ) 2 , 500mL water and 12g non-ionic surfactant P123, another beaker was added 23.6g benzimidazole, 500mL water, 200g 28%-30% ammonia solution and 200mL anhydrous methanol solution, stirred evenly for 30 minutes, filtered and separated, Dry at 90°C for 12 hours to obtain a metal imidazole coordination framework material. Its X-ray diffraction pattern is shown in Figure 5 , according to the comparison of literature (Science, 2008, 319, 939), it can be seen that this material corresponds to the Zif-67 sodalite (sod) topology. its microscopic appearance Image 6 Scanning electron micrograph, for nano-sized particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com