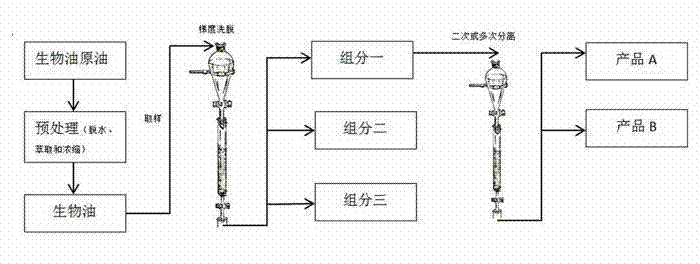

Separating and upgrading method of bio-oil by column chromatography

A technology of bio-oil and column chromatography, which is applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems that cannot be directly used as fuel, low calorific value of bio-oil, poor stability, etc., to achieve faster Study the pace, simplicity of the process, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

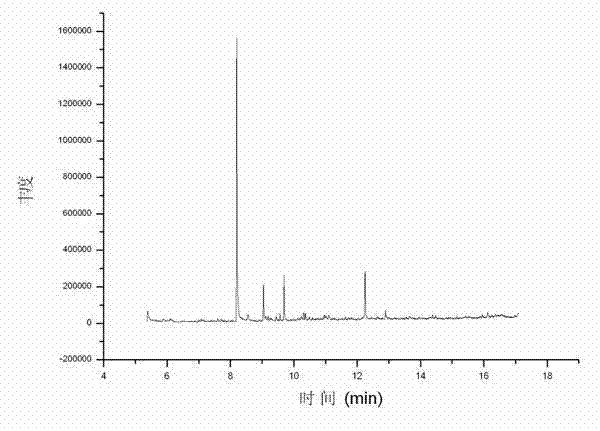

[0020] Extract the bio-oil crude oil produced by hydrothermal liquefaction of Enteromorpha at 280°C with dichloromethane, concentrate it to asphalt state by rotary evaporation, take a sample of 0.982g, dissolve it in 10ml of dichloromethane, add 1g of silica gel, mix well and spin The solvent was removed, and the obtained powder was evenly spread on the top layer of a silica gel chromatography column (25×750mm). After silica gel column chromatography, use n-hexane-dichloromethane-ethyl acetate gradient elution at room temperature, and then use n-hexane and dichloromethane at a volume ratio of 15:1 to elute for 60 minutes, dichloromethane, acetic acid The eluent with a volume ratio of ethyl ester of 10:1 was eluted for 60 minutes, and the eluent with a volume ratio of dichloromethane and ethyl acetate of 1:1 was eluted for 60 minutes. The column pressure is 5 bar, the flow rate of the eluent is 4 cm / min, and the collection is performed every 1 minute. GC-MS analysis shows that ...

Embodiment 2

[0022] Extract the bio-oil crude oil produced by hydrothermally liquefying rice straw at 300°C with ethyl acetate, concentrate it to asphalt state by rotary evaporation, take a sample of 0.993g, dissolve it in 5ml ethyl acetate, add 1g of silica gel, mix well and then spin off solvent, and the obtained powder was evenly spread on the top layer of the silica gel chromatography column (25×750mm). After silica gel column chromatography, use n-hexane-benzene-ethyl acetate gradient elution at room temperature, and then use n-hexane and benzene at a volume ratio of 15:1 to elute for 60 minutes, and benzene and ethyl acetate at a volume ratio of 10 : 1 eluent elution 60min, benzene, ethyl acetate volume ratio 1:1 eluent elution 60min. The column pressure is 5 bar, the flow rate of the eluent is 4 cm / min, and the collection is performed every 1 minute. GC-MS analysis shows that 4-ethyl guaiac is obtained at about 32 min, 72 min, 138 min, and 161 min after the elution starts. Maximum ...

Embodiment 3

[0024] The bio-oil crude oil produced by hydrothermal liquefaction of Salix salix at 280°C was extracted with tetrahydrofuran, concentrated by rotary evaporation to asphalt state, 0.972g was sampled, dissolved in 5ml of tetrahydrofuran, and 1g of silica gel was added, mixed well and then the solvent was rotated to obtain The powder was spread evenly on the top layer of the silica gel chromatography column (25×750mm). After silica gel column chromatography, use n-hexane-benzene-ethyl acetate gradient elution at room temperature, and then use n-hexane and benzene at a volume ratio of 15:1 to elute for 60 minutes, and benzene and ethyl acetate at a volume ratio of 10 : 1 eluent elution 60min, benzene, ethyl acetate volume ratio 1:1 eluent elution 60min. The column pressure was 5 bar, the flow rate of the eluent was 4 cm / min, and the samples were collected every 1 minute. According to GC-MS analysis, 4-ethylhexyl was obtained at about 35 min, 76 min, 122-132 min, and 163 min after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com