P/N-type laminated resistive random access memory for growing metal nano crystal particles spontaneously

A metal nanocrystal, resistive memory technology, applied in electrical components and other directions, can solve the problems of large randomness of nanocrystals, conductive channel size, number instability, difficult control of the number and size of nanocrystals, etc. control the fluctuation of device voltage and current, the effect of uniformity and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

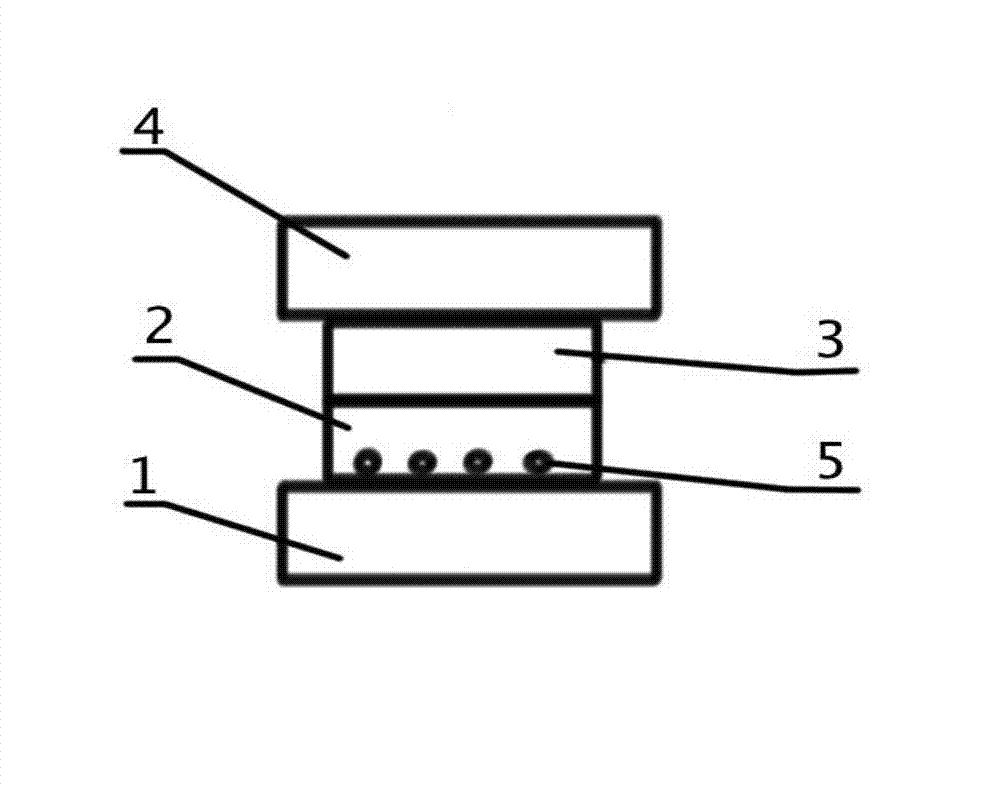

[0021] The resistive variable memory, as shown in the accompanying drawing, includes a lower electrode 1, an induction layer I2, an induction layer II3, an upper electrode 4, and an induction layer I2 in which metal nanocrystalline particles 5 are spontaneously formed; the lower electrode is made of 50nm copper metal, and the induction layer I use 100nm silicon dioxide doped with 3% phosphorus, and the induction layer II uses 100nm silicon dioxide doped with 3% boron; the upper electrode uses 50nm platinum metal.

[0022] The preparation steps of the resistive variable memory are as follows:

[0023] 1) Use PVD (physical vapor deposition) to deposit the lower electrode, which is 50nm thick metal copper;

[0024] 2) Use PVD (physical vapor deposition) to deposit induction layer I with silicon dioxide doped with 3% phosphorus, and its thickness is 100nm;

[0025] 3) Use PVD (physical vapor deposition) to deposit induction layer II silicon dioxide doped with 3% boron, with a thi...

Embodiment 2

[0029] The resistive variable memory, as shown in the accompanying drawing, includes a lower electrode 1, an induction layer I2, an induction layer II3, an upper electrode 4, and an induction layer I2 in which metal nanocrystalline particles 5 are spontaneously formed; the lower electrode is made of 50nm copper metal, and the induction layer 100nm titanium oxide is used for I, 100nm nickel oxide is used for the induction layer II; 50nm platinum metal is used for the upper electrode.

[0030] The preparation steps of the resistive variable memory are as follows:

[0031] 1) Use PVD (physical vapor deposition) to deposit the lower electrode, which is 50nm thick metallic copper;

[0032] 2) The induction layer I titanium oxide is deposited by DC magnetron sputtering method, the process parameters are 100W power, the working pressure is 1Pa, the oxygen partial pressure is 5%, the temperature is 300K, and its thickness is 100nm;

[0033] 3) The induction layer II nickel oxide is d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com