Preparation method of hollow fiber dispersion and dialysis alkali recycling membrane

A diffusion dialysis and hollow technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of small membrane area and small processing capacity, and achieve large processing capacity, small footprint and economic benefits significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

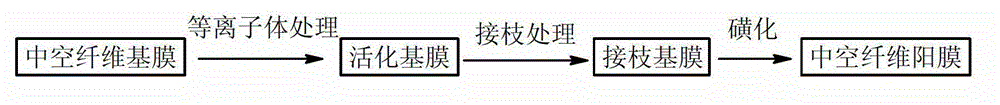

[0027] The polypropylene hollow fiber ultrafiltration commercial membrane is selected as the hollow fiber base membrane. The inner diameter of the hollow fiber base membrane is 0.45mm, the wall thickness is 0.2mm, and the membrane pore size is 0.1 micron. The hollow fiber base membrane is placed in a plasma chamber for plasma activation, the vibration frequency is 40MC, the purity of oxygen used is 99.5%, and the activation time is 30 minutes. The activated hollow fiber base membrane was immersed in a mixed solution of 85% styrene, 14.5% divinylbenzene and 0.5% benzoyl peroxide to carry out functional group grafting.

[0028] The grafted base membrane is sulfonated with silver sulfate as a catalyst and concentrated sulfuric acid as a sulfonating agent at 45°C for 8 hours. After cooling, separating and taking out, a hollow fiber diffusion dialysis alkali recovery membrane can be obtained. The ion exchange capacity is 0.7 meq / g film.

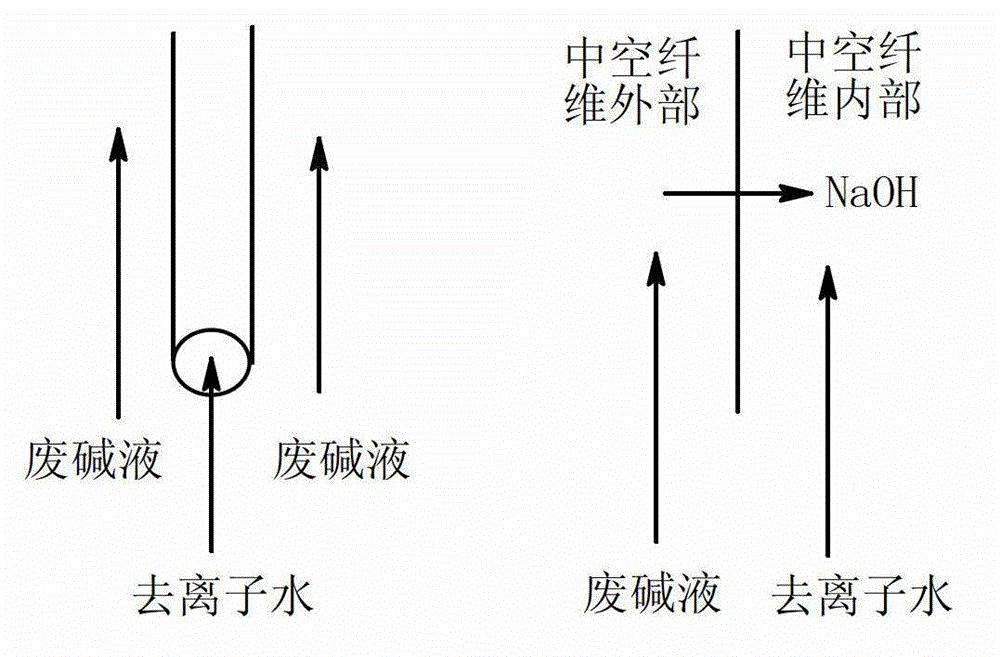

[0029] In this embodiment, the schematic d...

Embodiment 2

[0031] The polyacrylonitrile hollow fiber ultrafiltration commercial membrane is selected as the hollow fiber base membrane. The inner diameter of the hollow fiber base membrane is 0.6 mm, the wall thickness is 0.3 mm, and the membrane pore size is 0.15 microns. The hollow fiber base membrane is placed in a plasma chamber for plasma activation, the vibration frequency is 50MC, the purity of oxygen used is 99.8%, and the activation time is 40 minutes. The activated hollow fiber base membrane was soaked in a mixed solution of 75% styrene, 24% divinylbenzene and 1% benzoyl peroxide to carry out functional group grafting.

[0032] The grafted base membrane is sulfonated with silver sulfate as a catalyst and concentrated sulfuric acid as a sulfonating agent at 50°C for 6 hours. After cooling, separating and taking out, a hollow fiber diffusion dialysis alkali recovery membrane can be obtained. The ion exchange capacity is 0.6 meq / g film.

Embodiment 3

[0034] The nylon hollow fiber ultrafiltration commercial membrane is selected as the hollow fiber base membrane. The inner diameter of the hollow fiber base membrane is 0.7mm, the wall thickness is 0.4mm, and the membrane pore size is 0.1 micron. The hollow fiber base membrane is placed in a plasma chamber for plasma activation, the vibration frequency is 45MC, the purity of oxygen used is 99.5%, and the activation time is 50 minutes. The activated hollow fiber base membrane was immersed in a mixed solution of 80% styrene, 20% divinylbenzene and 1% benzoyl peroxide to carry out functional group grafting.

[0035] The grafted base membrane is sulfonated with silver sulfate as a catalyst and concentrated sulfuric acid as a sulfonating agent at 50°C for 7 hours. After cooling, separation and removal, a hollow fiber diffusion dialysis alkali recovery membrane can be obtained. The ion exchange capacity is 0.7 meq / g film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com