Catalyzing system for isoprene polymerization and preparation and application method of catalyzing system

A catalytic system and technology of isoprene, applied in the field of catalytic system for isoprene polymerization and its preparation and application, can solve the problem of polymer molecular weight and wide distribution, high dynamic viscosity of polymerization system, lower production capacity and Efficiency and other issues, to achieve high catalytic activity and homogeneous system stability, small temperature fluctuations, easy to react

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

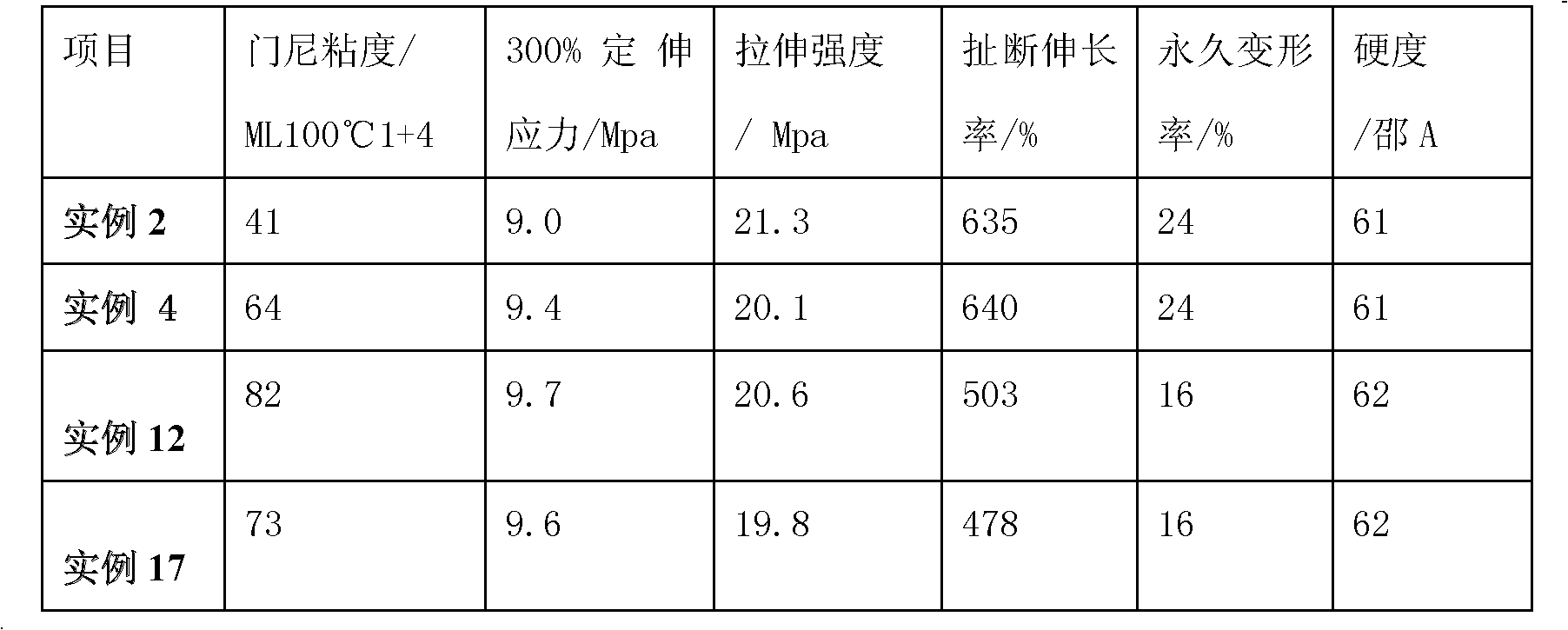

Examples

Embodiment 1

[0042] Under nitrogen protection at 6°C, neodymium isooctanoate (3.5mmol), diisobutylaluminum hydride (35mmol), diethylaluminum chloride (7mmol), ethyl acrylate (5ml, molar weight 42.5mmol) and acetic acid The solution of benzyl ester (8ml, the molar weight is 45.3mmol) was respectively added to clean 250ml horn bottles equipped with hexane, and the concentration of neodymium was prepared to be 0.014mol / L, mixed evenly, and after aging for 3h, a light green transparent homogeneous Prepolymer active center catalytic system solution.

[0043] Under the protection of nitrogen, add 2L of hexane and 300ml of isoprene solution (wherein the monomer mass concentration is 13%) in the polymerization reactor of 2.5 liters at 20 ℃, then add above-mentioned catalytic system solution 25ml, (neodymium / monomer=0.17mmolNd / 100g isoprene) start stirring to carry out polymerization, the initiation time is 3min, after reacting for 3h, add 2,6-di-tert-butyl-p-methylphenol hexane solution containin...

Embodiment 2

[0045] Under nitrogen protection at 45°C, neodymium isooctanoate (3.5mmol), diisobutylaluminum hydride (56mmol), diethylaluminum chloride (10.5mmol), methyl acrylate (10ml, molar weight is 98.8mmol) and A solution of benzyl acetate (15ml, molar weight 85.0mmol) was added to a clean 250ml horn bottle filled with hexane to prepare a neodymium concentration of 0.014mol / L, mixed evenly, and aged for 3 hours to obtain a light yellow-green transparent homogeneous phase of the prepolymer active site catalyst solution.

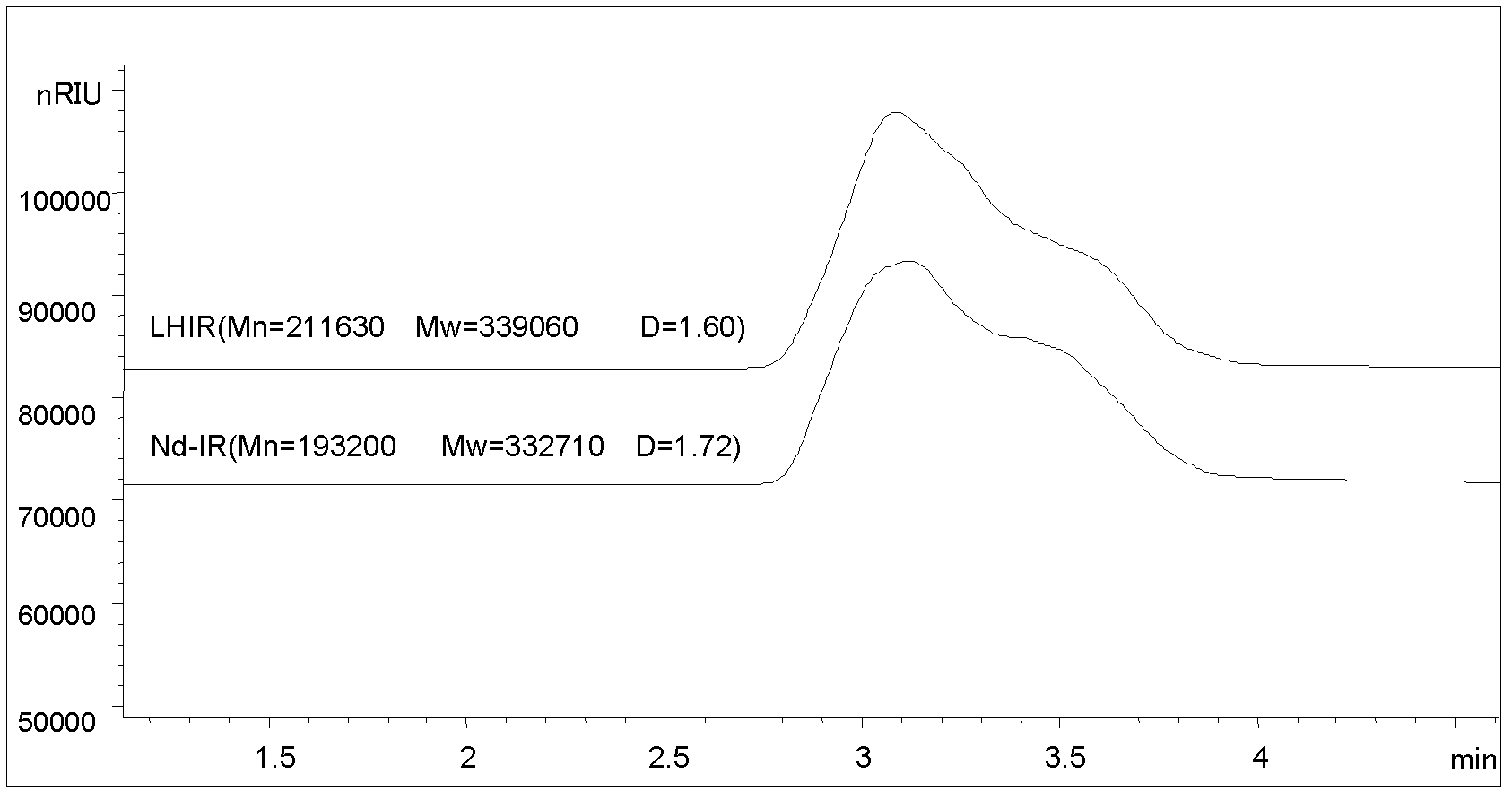

[0046] Under nitrogen protection, add 1.5L of hexane / cyclohexane mixed solvent and 400ml of isoprene solution (wherein hexane / cyclohexane=1:1, monomer mass concentration 21%), then add 35ml of the above catalyst solution, (neodymium / monomer = 0.18mmolNd / 100g isoprene) start stirring to polymerize, the initiation time is 4min, after 3h of reaction, add the catalyst solution containing 0.5% mass fraction A solution of 2,6-di-tert-butyl-p-methylphenol in hexane terminat...

Embodiment 3

[0054] Under nitrogen protection at 20°C, neodymium isooctanoate (3.5mmol), diisobutylaluminum hydride (40mmol), triisobutylaluminum (12.5ml), diethylaluminum chloride (9.8mmol), methacrylic acid The solutions of methyl ester (10ml, molar weight 88.0mmol) and benzyl formate (27ml, molar weight 174.8mmol) were respectively added to a clean 250ml horn bottle filled with hexane, and the concentration of neodymium was prepared to be 0.014mol / L, and mixed evenly , After aging for 3h, a light green transparent homogeneous prepolymer catalyst solution was obtained.

[0055] Under nitrogen protection, add the hexane solvent of 1.3L and the isoprene of 400ml (wherein the mass concentration of monomer is 23.5%) in the polymerization reactor of 2.5 liters at 60 ℃, then add above-mentioned catalyst solution 30ml (Nd / monomer=0.15mmolNd / 100g isoprene), start stirring to carry out polymerization, the initiation time is 3min, after reacting for 3h, add a hexane solution containing 0.5% by ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com