Method for preparing marine environment-friendly calcium citrate hard tissue repair material

A technology of calcium citrate and repair materials, which is applied in carboxylate preparation, medical science, prosthesis, etc. It can solve the problems of difficult biodegradation or absorption, high price, and application limitations, etc., and achieves prolonged degradation time and good mechanical strength , the effect of extensive application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

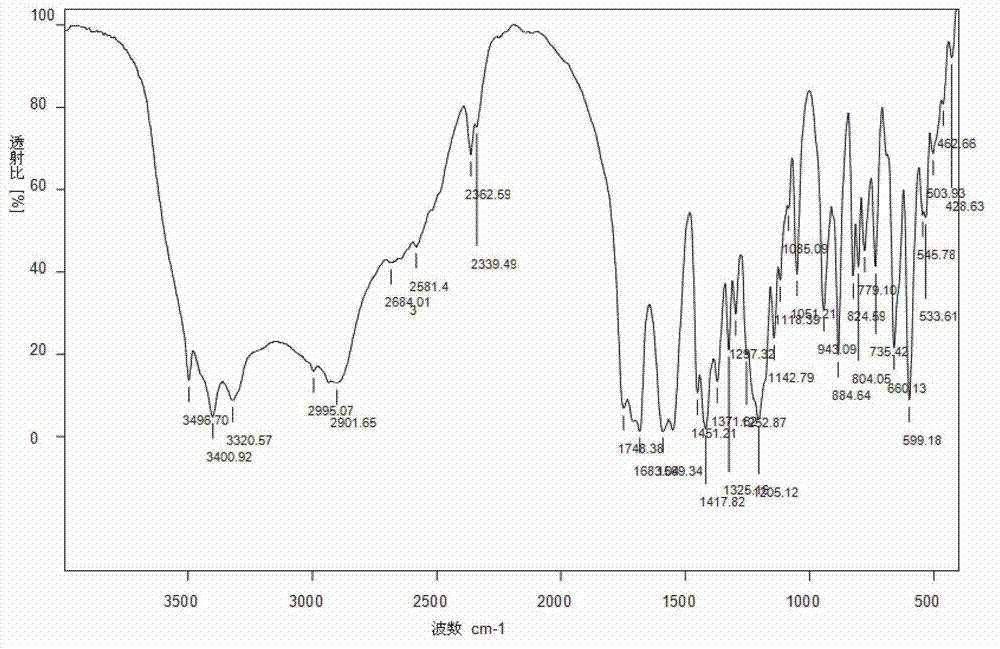

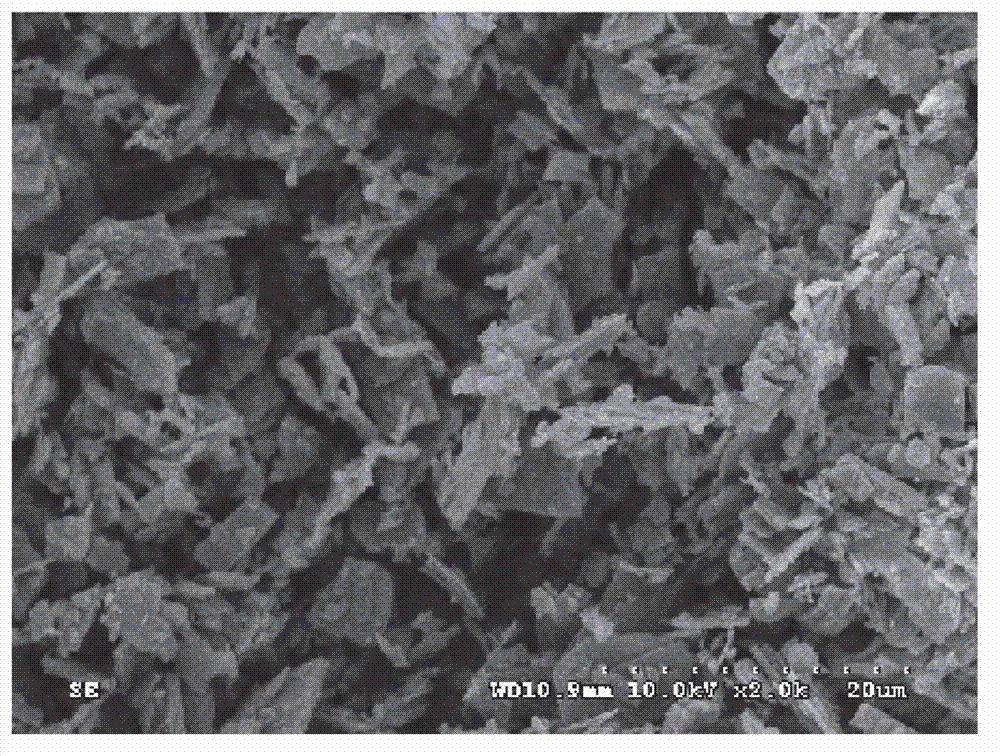

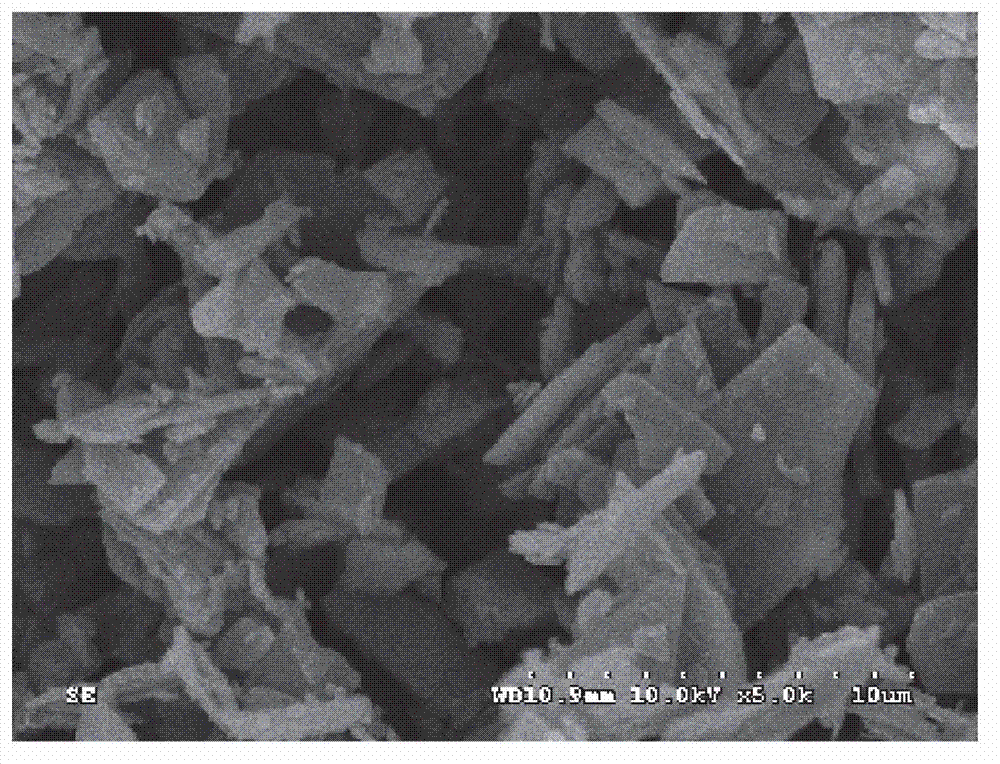

Embodiment 1

[0020] Choose fresh oyster shells from non-polluted sea areas, soak them in tap water for 4-5 hours, soak them in 40% acetic acid for 2 hours, soak them in deionized water until they are neutral, clean the dried oyster shells with ultrasonic waves in water medium, frequency 20KWz, Ultrasound of 40W / L solution was used to clean oyster shells. After ultrasonic cleaning, put them into blast drying oven for 24 hours to dry at a temperature of 60 o c. The clean oyster shells are pulverized into granules by a pulverizer, and passed through a 200-mesh sieve to obtain oyster shell powder. Gradually add a small amount of oyster shell powder to the analytically pure supersaturated citric acid solution, and shake the reaction vessel after fully reacting. When no bubbles overflow, no foam is generated, and the amount of sediment has no obvious increase or decrease, centrifuge at a centrifugal speed of 16000r / min for 20 minutes, take the precipitate, and dry it for 24 hours to obtain calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com