Catalyst for purifying automobile exhaust

A technology for purifying catalysts and automobile exhaust gas, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low pollutant conversion rate, high price, deactivation, etc. environment, the effect of avoiding churn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

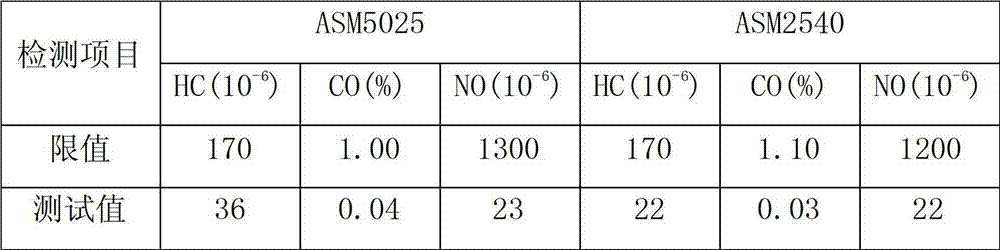

Embodiment 1

[0014] 1. Preparation of mesoporous catalysts: Cu, Al, Cr, and Ag were respectively loaded onto the inner channel surface of mesoporous molecular sieve SBA-15 with a pore size of 30-50 nm by impregnation method to obtain a mesoporous catalyst Cu-Al / SBA -15, Cr / SBA-15 and Ag / SBA-15; among them, the mass fraction of Cu and Al in Cu-Al / SBA-15 is 13.7%, and the mass ratio of Cu and Al is 1:2; Cr / SBA- The mass fraction of Cr in 15 is 7.0%; the mass content of Ag in Ag / SBA-15 is 5.5%;

[0015] 2. The first layer of coating: coating the alumina and additive slurry on the cyanite honeycomb carrier and drying it; the mass ratio of alumina and additives is 5:1; the additives are lanthanum oxide and cerium oxide , its mass ratio is 1:1;

[0016] 3. Mix the Cu-Al / SBA-15, Cr / SBA-15, and Ag / SBA-15 prepared in step 1 in a mass ratio of 2:2:1 and add them to a ball mill to effectively grind and mix them, and mix them Finally, it is a mesoporous material, and then it is evenly stirred with a...

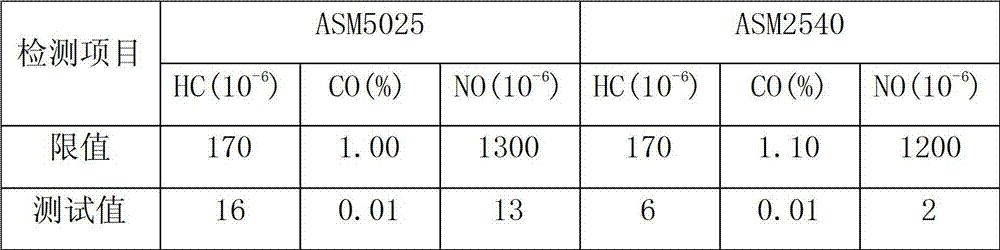

Embodiment 2

[0022] 1. Preparation of mesoporous catalyst: Al / SBA-15 was prepared by in situ synthesis method, then Fe-Al / SBA-15 was obtained by impregnation method, and Cr / SBA-15, Mn / SBA-15 were directly prepared by impregnation method , that is, Fe, Al, Cr, and Mn are loaded onto the surface of the inner channel of mesoporous molecular sieve SBA-15 with a pore size of 5-20 nm; wherein, the mass fraction of Fe and Al in Fe-Al / SBA-15 is 12.3%, and Fe The mass ratio of Al and Al is 1:3; the mass fraction of Cr in Cr / SBA-15 is 8.4%; the mass content of Mn in Mn / SBA-15 is 6.1%;

[0023] 2. The first layer of coating: coating the alumina and additive slurry on the aluminum alloy honeycomb carrier and drying it; the mass ratio of alumina and additive is 10:3; the additive is neodymium oxide and zirconium oxide , its mass ratio is 2:1;

[0024] 3. Mix Fe-Al / SBA-15, Cr / SBA-15, and Mn / SBA-15 prepared in step 1 in a mass ratio of 2:1:1 and add them to a ball mill for effective grinding and mixing....

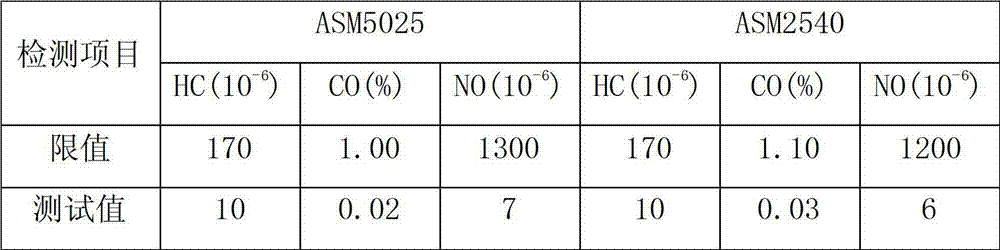

Embodiment 3

[0030] 1. Preparation of mesoporous catalysts: V / SBA-15 was prepared by in situ synthesis method, and Co / SBA-15 was prepared by impregnation method, that is, V and Co were respectively loaded onto mesoporous molecular sieve SBA- The surface of the inner channel of 15; wherein, the mass fraction of V in V / SBA-15 is 8.6%; the mass fraction of Co in Co / SBA-15 is 7.4%;

[0031] 2. The first layer of coating: Coat the alumina and additive slurry on the cyanite honeycomb carrier and dry it; the mass ratio of alumina and additive is 3:1; the additive is titanium oxide and molybdenum oxide , its mass ratio is 1:2;

[0032] 3. Mix the V / SBA-15 and Co / SBA-15 prepared in step 1 in a mass ratio of 1:1 and add them into a ball mill to grind and mix them effectively. After mixing, they will become mesoporous materials, and then mix them with Alumina, auxiliary agent slurry is stirred evenly, is coated on the first layer of coating prepared in step 2, and described auxiliary agent is titani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com