Precise molding method of biomimetic micro-channel system based on plant veins

A micro-channel and leaf-vein technology, which is applied in the field of precise forming of bionic micro-channel systems based on plant leaf veins, can solve the problems of affecting the structural performance of the micro-channel system, expensive, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

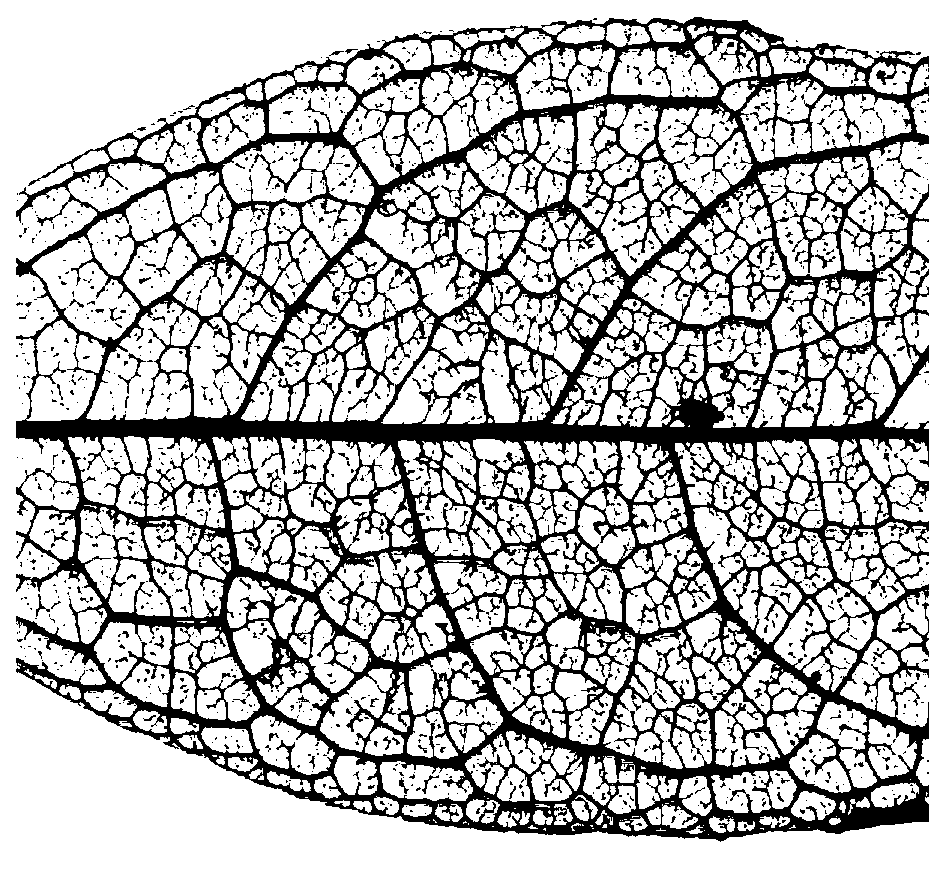

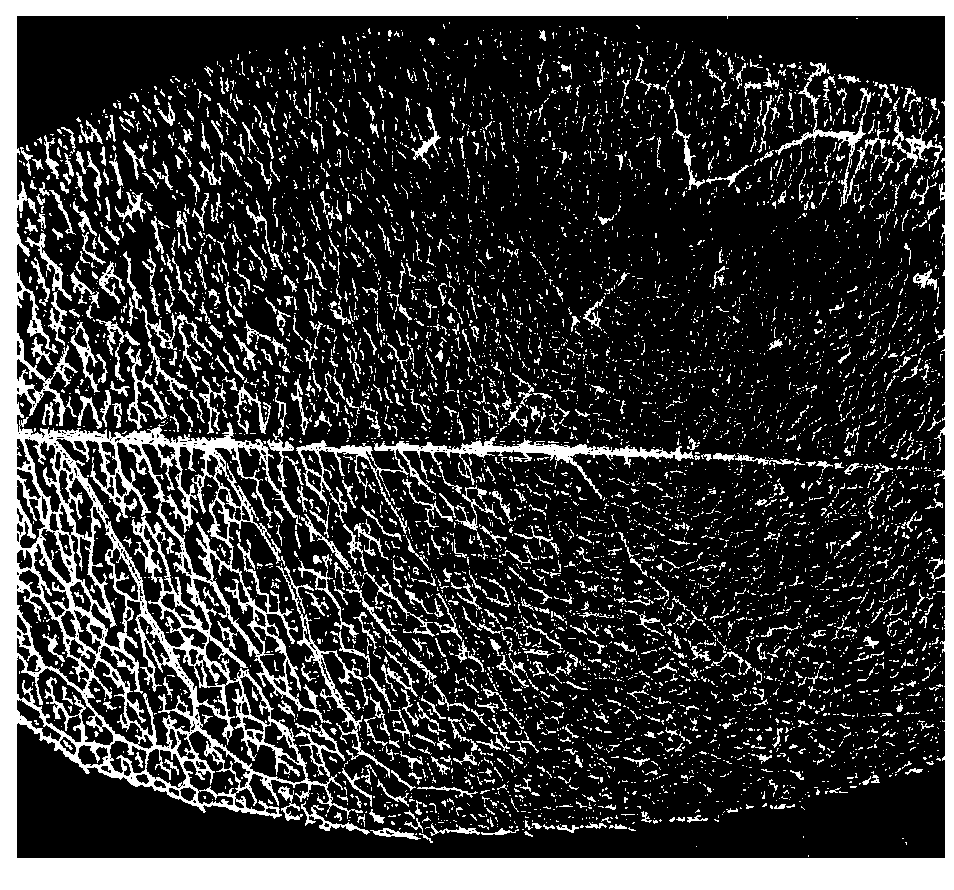

[0022] A method for precisely forming a bionic microfluidic channel system based on plant leaf veins, comprising the following steps:

[0023] 1) Prepare 7% sodium hydroxide aqueous solution and 5% sodium bicarbonate aqueous solution respectively, mix the two solutions evenly according to the volume ratio of 1:1, and pick fresh laurel leaves with hard leaves and clear veins , put the leaves of osmanthus osmanthus into the mixed solution and heat it to boiling, take it out after 15 minutes and wash it in water, and use a brush to completely peel off the mesophyll part, flatten and dry in an oven at 50°C to obtain a complete leaf vein structure, and then remove the leaf veins sputtering a layer of the first metal chromium film with a thickness of 400 nanometers on the surface of the structure to obtain a vein mask;

[0024] 2) Add the hexamethyldisilazane tackifier dropwise on the surface of the silicon wafer, spin coat it at a speed of 1000 rpm for 10 seconds, let it stand at 9...

Embodiment 2

[0032] A method for precisely forming a bionic microfluidic channel system based on plant leaf veins, comprising the following steps:

[0033] 1) Prepare 7% sodium hydroxide aqueous solution and 5% sodium bicarbonate aqueous solution respectively, mix the two solutions evenly according to the volume ratio of 1:1, and pick fresh mulberry leaves with hard leaves and clear veins, Put the mulberry leaves into the mixed solution and heat it to boiling. After 10 minutes, take it out and wash it in water, and use a brush to completely peel off the mesophyll. After flattening and drying at room temperature, a complete leaf vein structure is obtained, and then sputter on the surface of the leaf vein structure A first metal chromium thin film with a thickness of 300 nanometers to obtain a vein mask;

[0034] 2) Add the hexamethyldisilazane tackifier dropwise on the surface of the transparent glass sheet, spin coat it at a speed of 1000 rpm for 10 seconds, let it stand at 95°C for 15 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com