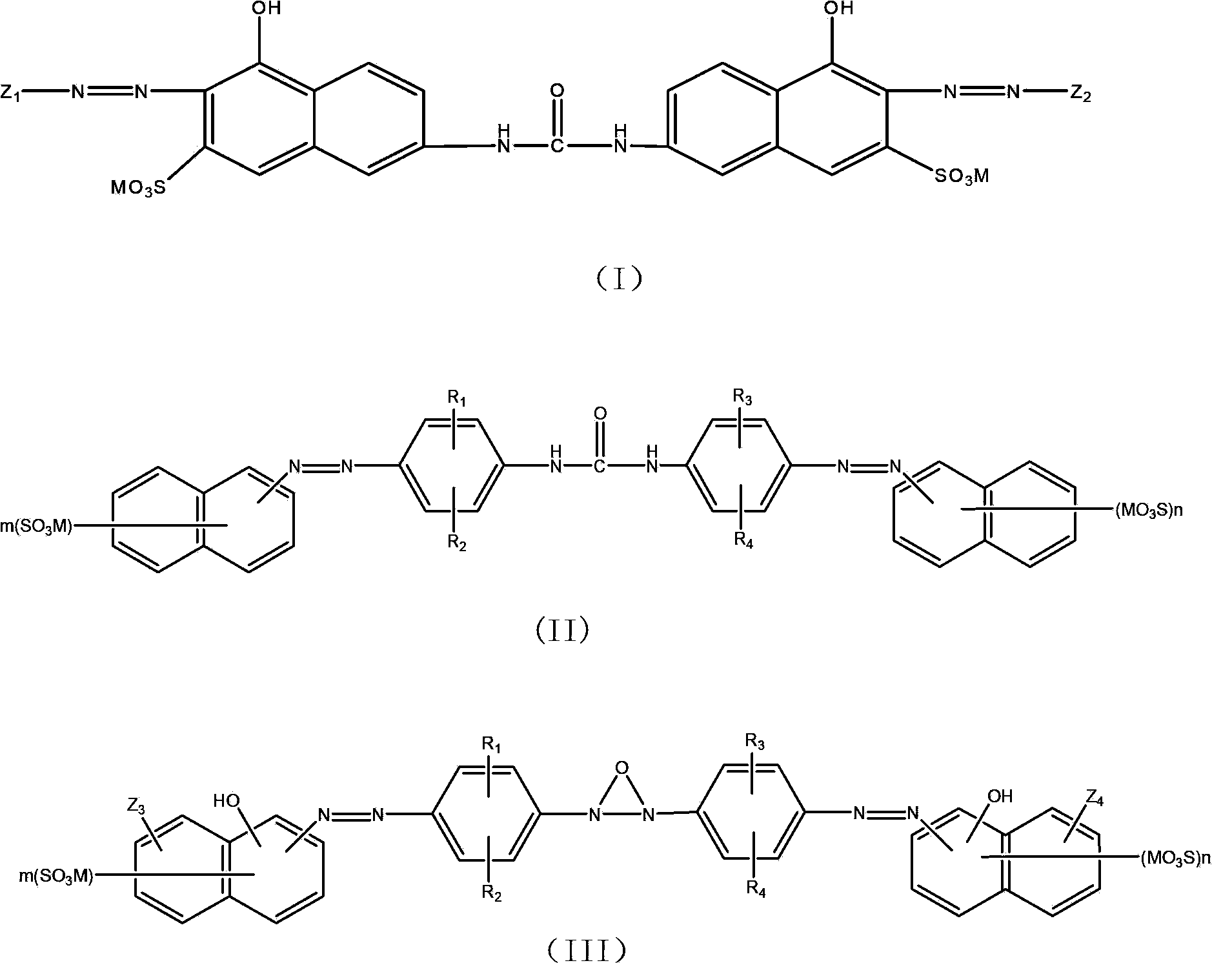

Water-based disazo dye mixture, and preparation method and application thereof

A disazo dye and disazo technology, applied in dyeing, organic dyes, textiles and papermaking, etc., can solve the problems affecting the storage stability of black liquid mixture, poor sunlight durability, poor water fastness, etc., and achieve excellent Long-term storage stability, good light resistance, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

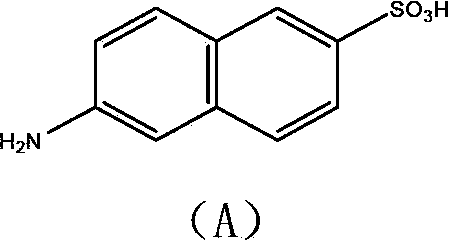

[0053] The present invention relates to the synthesis of a dye (I-1), comprising the following steps:

[0054]

[0055] Step 1: Dissolve 23.8g (99%) neopentyl glycol in 20g water, add 20g ice and 31.64g (99%) sodium nitrite, stir evenly, then slowly add 55.6g of 30% hydrochloric acid, temperature control Stirring was continued for 30 minutes below 5°C, poured into a separatory funnel, and allowed to stand for layers to obtain 36.5 g (98% of theoretical value) of neopentyl glycol dinitrite in the organic layer. RfnD22=1.4070;

[0056] Step 2: Disperse 47.8g of Gamma Acid in 100g of water, stir slowly at room temperature, cool down to below 5°C, add 36.5g of neopentyl glycol dinitrite dropwise, the dropwise addition ends in 2 hours, and the temperature is always controlled at 5°C Below ℃, keep warm for 2 hours, measure the end point with potassium iodide test paper, and remove excess nitrite with sulfamic acid;

[0057] Step 3: Disperse 54.8g of J-Acid urea in 800g of water, ...

Embodiment 2

[0059] The present invention relates to the synthesis of a dye (II-1), comprising the following steps:

[0060]

[0061] Step 1: Add 86.5g (0.2mol, 70.1%) of amino acid C, 300g of water and 53g of 31% concentrated hydrochloric acid to a 500ml three-neck flask equipped with a stirring, thermometer and dropping funnel, stir, and dropwise add A solution composed of 50g (30%, mass ratio) of NaNO2 aqueous solution. After the dropwise addition, react at 5°C for two hours, and urea decomposes excess nitrous acid. Adjust the pH value of the reaction solution to 5-6, add 22 g (0.2 mol) of m-aminotoluene dropwise, and react at 5-10° C. for 0.5 hour after the dropwise addition to obtain a monoazo dye.

[0062] Step 2: Add the monoazo dye obtained in Step 1 to 200ml of buffer solution of disodium hydrogen phosphate with pH=6.5, 1ml of catalyst triethylamine, stir, add 15g of triphosgene in batches, and react at 30°C. During the reaction, 10% NaOH continuously adjusted the pH value to...

Embodiment 3

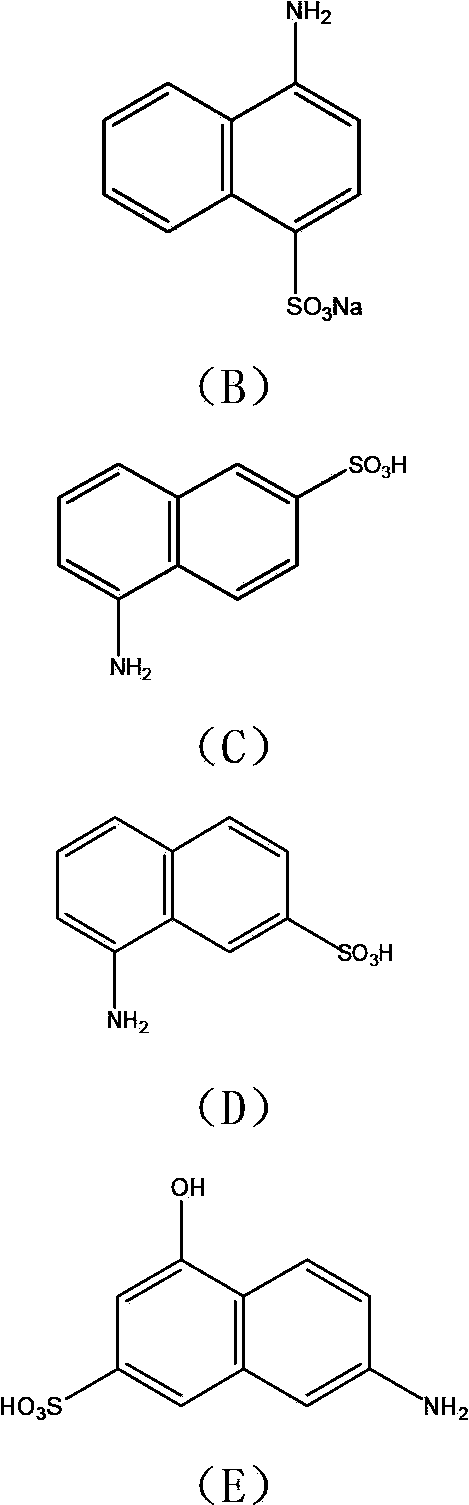

[0064] The present invention relates to the synthesis of a dye (III-1), comprising the following steps:

[0065]

[0066] Step 1: Disperse 30.4g (0.1mol) of 1-naphthol-3,6-disulfonic acid in 600g of water, adjust the pH of the above solution to 2.5 with 32% hydrochloric acid, and stir to form a uniform suspension. After cooling to 5°C, 54g of ethyl chloroformate was slowly added dropwise within 1 hour, at this time the temperature rose slowly to 32°C, and then 30% sodium hydroxide solution was added to maintain the pH at 2.5. The temperature was maintained at 35°C until there was no change in pH.

[0067] Step 2: In another flask, add 16.8g (0.1mol) 2-amino-5-nitroanisole, 100g water, 35g 30% hydrochloric acid, cool down to about 0°C, add dropwise 14g (50%, mass than) NaNO2 aqueous solution for diazotization reaction, after the dropwise addition, keep warm at 0-5°C for 1 hour, and sulfamic acid removes excess sodium. Then slowly add the diazonium salt into the above solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com