Epoxy resin nano composite adhesive film and preparation method thereof

An epoxy resin and nano-composite technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of poor heat resistance, low strength, inconvenient use, etc., and achieve excellent thermal stability and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 450g of epoxy resin, 450g of acrylate rubber, and 100g of curing agent into the acetone solvent, and completely dissolve to obtain a blended solution; use a professional coating tool to coat the blended solution on the PTFE film substrate to control the finished product. The thickness of the adhesive film is 80um; it is placed at room temperature for 24 hours, and then volatilized at room temperature and vacuum for 12 hours to completely remove the acetone and peel off from the substrate to obtain the finished product of the adhesive film.

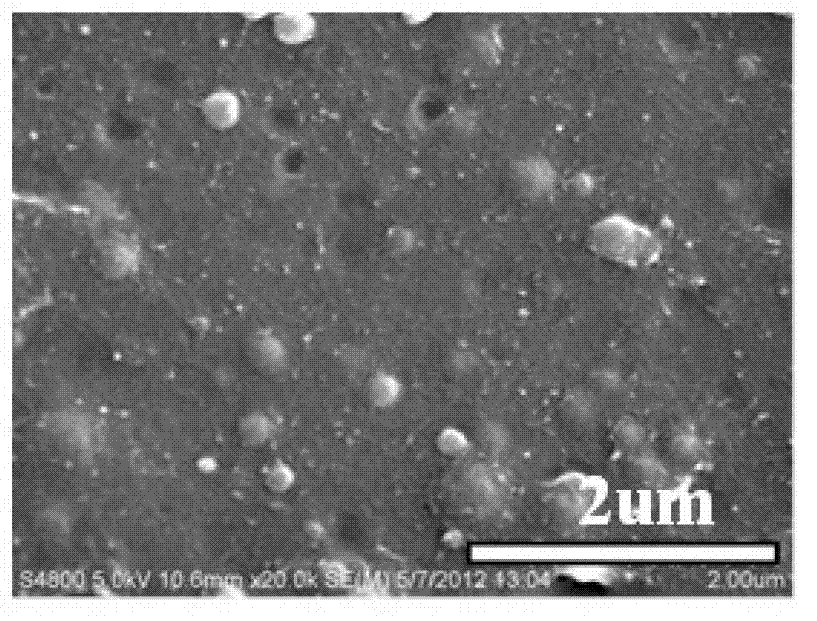

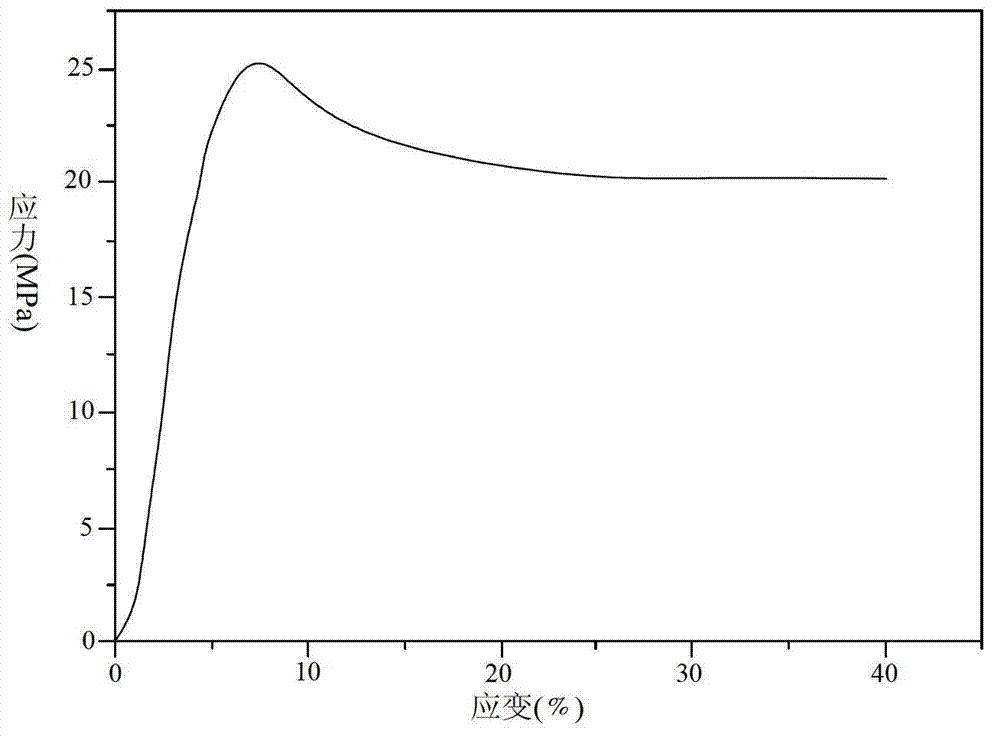

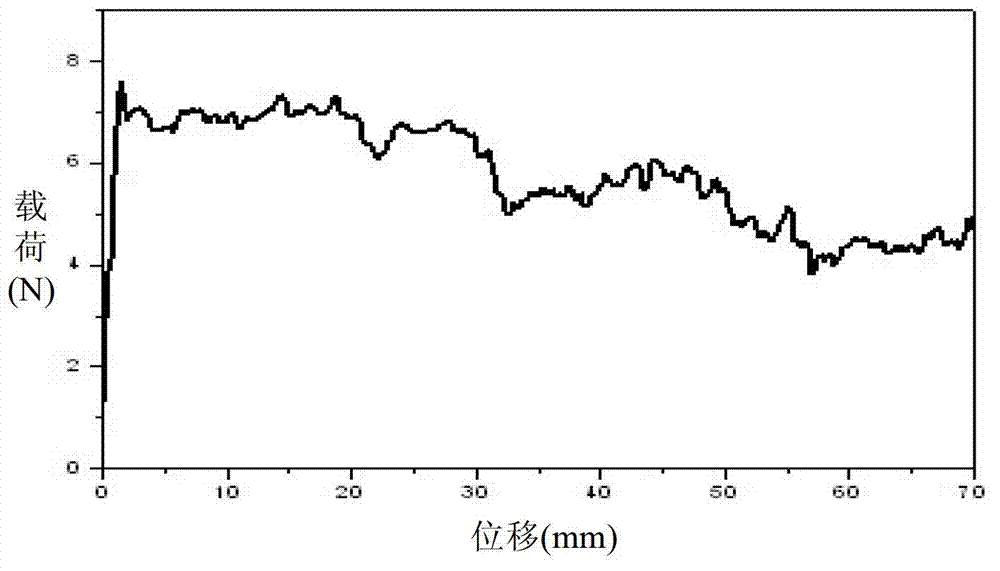

[0030] The adhesive film was cross-linked and cured in a vacuum environment at 120°C for 4 hours, quenched in a liquid nitrogen environment, and observed with a scanning electron microscope after spraying gold. The fracture surface morphology was as follows: Picture 1-1 As shown, the average diameter of the dispersed phase (epoxy resin-rich phase) is as high as 410 nm. The Young's modulus of the bonding film is 460 MPa, and the ...

Embodiment 2

[0032] Add 425g of epoxy resin, 425g of acrylate rubber, and 50g of curing agent into the acetone solvent, and obtain a blended solution after completely dissolving; add 100g of nano-silica filler into the blended solution, and disperse for 10 minutes to obtain a uniformly dispersed solution; The uniformly dispersed solution is coated on the PTFE film substrate with a professional coating tool, and the thickness of the finished adhesive film is controlled to be 100um; placed at room temperature for 30 hours, and then volatilized at room temperature and vacuum for 15 hours to completely remove acetone and peel off from the substrate Finally, the finished adhesive film is obtained.

[0033] The adhesive film was cross-linked and cured in a vacuum environment at 120°C for 4 h, quenched in a liquid nitrogen environment, and observed by scanning electron microscope after spraying gold. The fracture surface morphology was as follows: diagram 2-1 As shown, the diameter of the disper...

Embodiment 3

[0035] Add 300g of epoxy resin, 600g of acrylate rubber, and 75g of curing agent into the acetone solvent, and obtain a blended solution after completely dissolving; add 25g of nano-silica filler into the blended solution, and disperse for 5 minutes to obtain a uniformly dispersed solution ; Coat the evenly dispersed solution on the polytetrafluoroethylene film substrate with a professional coating tool, and control the thickness of the finished adhesive film to 50um; place it at room temperature for 24 hours, and then volatilize it at room temperature and vacuum for 24 hours to completely remove acetone, from the substrate After peeling off the sheet, the finished adhesive film was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com