Leadless brass alloy and preparation method thereof

A lead-free brass and alloy technology, applied in the direction of improving process efficiency, can solve the problems of limited resources, low yield and high production cost, achieve good cutting performance and corrosion resistance, low alloy preparation cost, and improve processing. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

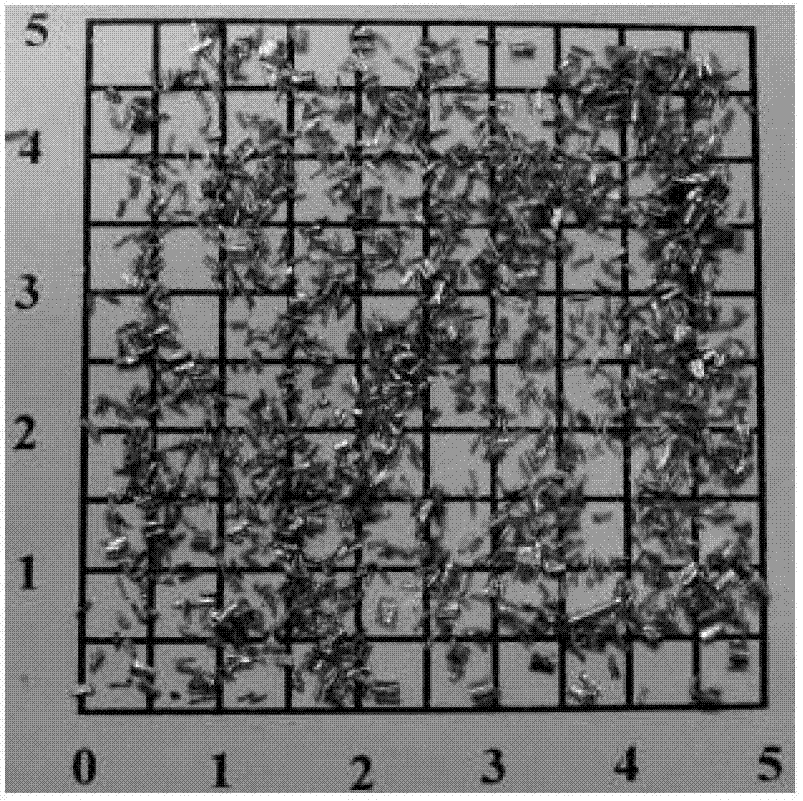

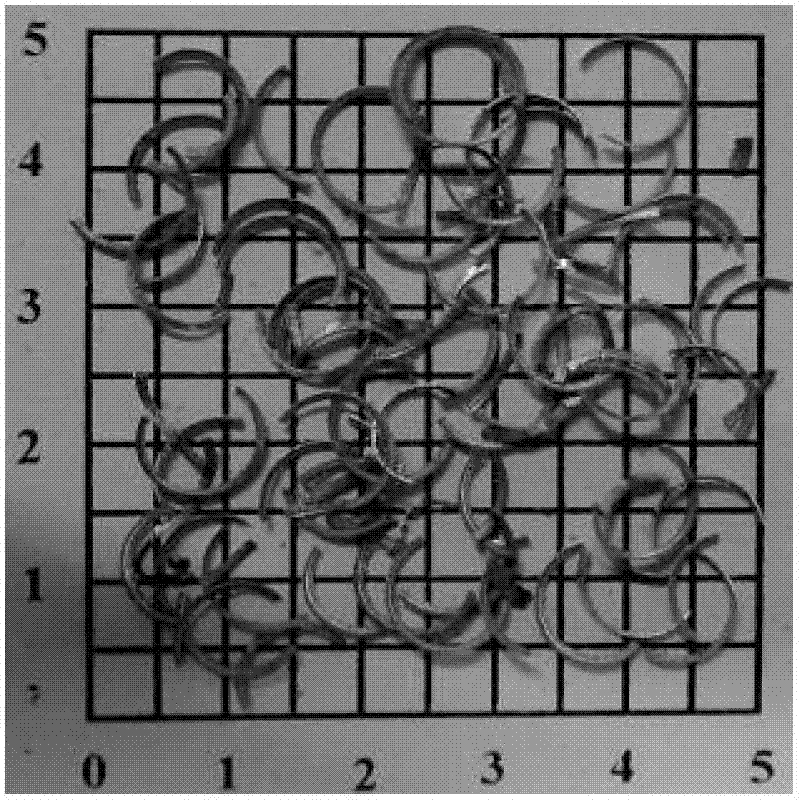

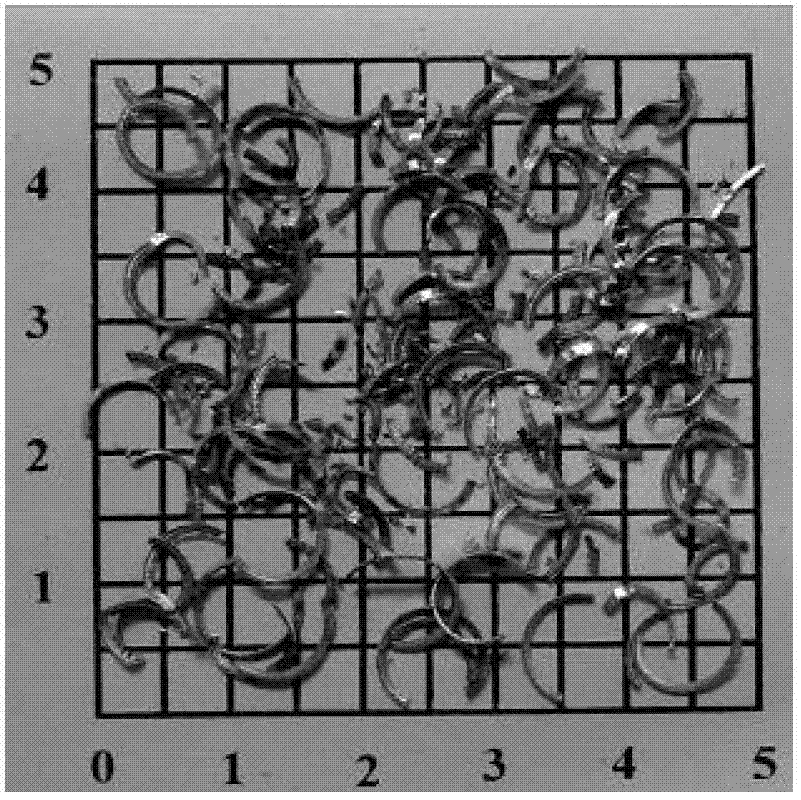

Image

Examples

Embodiment Construction

[0024] The preparation method of lead-free brass alloy of the present invention, comprises the steps:

[0025] 1. Raw material pretreatment: grading, sorting, and pretreatment (oil removal, dust removal, and water removal) for the recycled brass, zinc white copper, and tin phosphor bronze waste materials;

[0026] 2. Alloy preparation: according to the composition of the alloy described in Table 1, calculate the alloy ingredients and prepare the charge;

[0027] Alloy batching method: Proportion according to the total weight of copper in the alloy, 75-85% of brass, 10-15% of tin phosphor green, 5-10% of zinc white copper, and the rest of the alloys are analyzed according to the composition of the old materials after melting the old materials. Ingredient weight percentage ingredients;

[0028] 3. Alloy smelting: when smelting, first add recycled brass, zinc white copper, and tin phosphor bronze waste materials, and then add other alloys; Wait);

[0029] 4. Alloy refining: Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com