Weaning sow premix and producing method thereof

A premix and sow technology, applied in animal feed, animal feed, application, etc., can solve the problems of high transportation cost and complicated production process, and achieve the goal of enhancing ovarian function, increasing feed intake, and enhancing disease resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

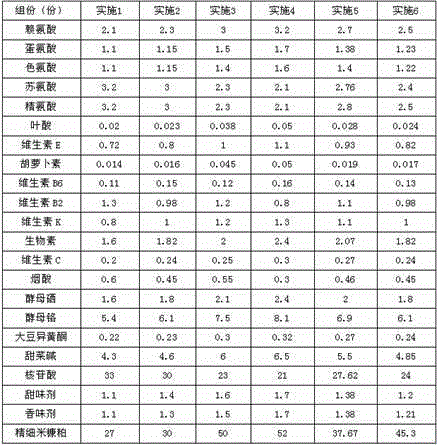

Examples

Embodiment 7

[0036] Corn 20.04g, soybean meal (43%) 15.7g, wheat 45g, corn distiller's grains 5g, puffed soybean 5g, rice bran meal 2.6g, imported fish meal 1.5g, soybean oil 1g, stone powder 1g, calcium hydrogen phosphate 1.25g, salt 0.35g , lysine sulfate (54%) 0.37g, threonine (98.5%), choline chloride (50%) 0.37g, phytase 0.01g, weaning sow health care premix 0.7g, trace elements Additive 0.2g, multivitamin 0.12g.

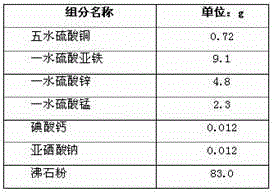

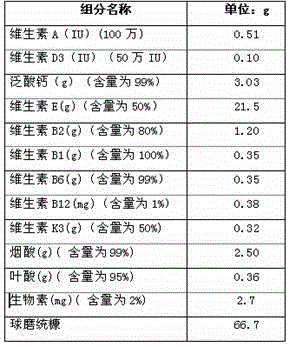

[0037] Each component in the weaned sow premix is prepared according to Example 5, the trace element additive is made of the components in Table 1, and the multivitamin is made of the components in Table 2:

[0038] Table 2

[0039]

[0040] table 3

[0041]

[0042]The specific preparation process is as follows: the corn and wheat are passed through a three-layer cylinder primary cleaning sieve, and the parameters are: the inner sieve is 18.0-20.0mm, the middle sieve is 5.5mm, and the outer sieve is 2.5mm. The sieved corn, soybean meal a...

Embodiment 8

[0044] Corn 19.42g, wheat 55.37g, soybean meal (43%) 16.43g, soybean oil 1.88g, puffed soybean 2g, imported fish meal 1g, resame sweet 0.01g, calcium powder 0.78g, calcium hydrogen phosphate 1.45g, salt 0.04g, Phytase 0.01g, choline chloride (50%) 0.1g, lysine sulfate (65%) 0.45g, weaning sow premix 0.6g, trace element additive 0.4g, multivitamin 0.06g. Wherein, each component in the premix for weaned sows is prepared according to Example 6, the trace element additive is composed of the components in Table 3, and the composite microorganism is composed of the components in Table 4.

[0045] Table 4

[0046]

[0047] table 5

[0048]

[0049] The specific preparation process is as follows: the corn and wheat are passed through a three-layer cylinder primary cleaning sieve, and its parameters are: the inner sieve is 18.0-20.0mm, the middle sieve is 5.5mm, and the outer sieve is 2.5mm. After sieving, the corn and soybean meal are crushed ...

Embodiment 9

[0051] Corn 28.41g, soybean meal (43%) 13.56g, corn distillers grains 4.7g, wheat 38.44g, rice bran meal 2.9g, puffed soybean 5.1g, imported fish meal 1.4g, soybean oil 1g, stone powder 1.12g, calcium hydrogen phosphate 1.13 g, salt 0.4g, lysine sulfate (54%) 0.35g, choline chloride (50%) 0.1g, phytase 0.01g, threonine 0.08g, weaning sow premix 0.8g, Trace element additive 0.45g, multivitamin 0.05g.

[0052] Each component in the weaned sow premix is prepared by embodiment 1, and the trace element additive is made of table 5 components, and multivitamin is made of table 6 components:

[0053] Table 6

[0054]

[0055] Table 7

[0056]

[0057] The specific preparation process is as follows: the corn and wheat are passed through a three-layer cylinder primary cleaning sieve, and its parameters are: the inner sieve is 18.0-20.0mm, the middle sieve is 5.5mm, and the outer sieve is 2.5mm. The sieved corn, soybean meal and rice bran meal are crush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com