Clean type hydrocarbon steam pre-conversion catalyst and preparation method thereof

A catalyst and pre-conversion technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high production cost, achieve high mechanical strength and good activity , structural stability and good activity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

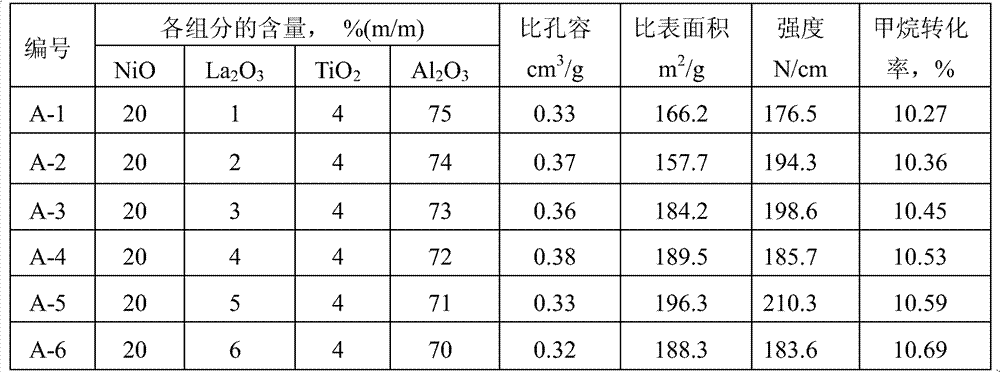

Embodiment 1

[0026] Weigh 500.0g of aluminum rubber powder, add 50.0g of titanium dioxide, 2.6g of turnip powder and 3.4g of polyvinyl alcohol, and 280mL of water, 20mL of oxalic acid, fully knead, and shape it into an outer diameter Φ5.0mm, length 5.0mm Flaky, calcined at 950°C to obtain an alumina carrier; prepare a lanthanum acetate impregnation solution with a concentration of 0.01mol / L, soak the carrier in the solution for 140min, take it out and drain it, and dry it at a temperature of 120°C 180min, then roasted and decomposed at 900°C for 180min to obtain a modified carrier; prepare a nickel acetate active solution with a concentration of 1.50mol / L, immerse the modified carrier in the active solution for 140min, take it out and drain it, and dry it at a temperature of 120°C 180min, then calcined and decomposed at 400°C for 180min, then impregnated with nickel acetate solution, dried and calcined repeatedly to obtain catalyst A-1. The content, pore structure data, strength data and e...

Embodiment 2

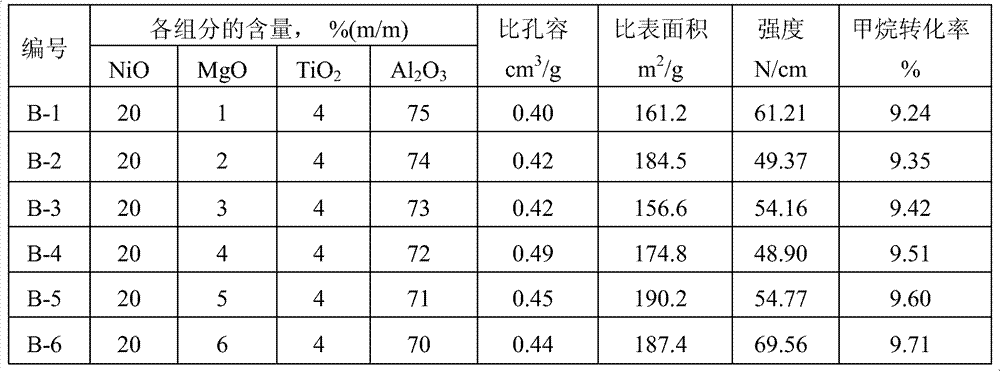

[0031] Weigh 500.0g of pseudo-boehmite, add 50.0g of titanium dioxide, 4.5g of acetic acid, 3.2g of scallop powder, 300mL of water, 20mL of citric acid, fully knead, and shape it into an outer diameter of Φ4.5mm and a length of 4.0mm The Raschig cyclic shape is calcined at 860°C to obtain an alumina carrier; prepare a mixed impregnation solution of nickel and magnesium oxalate, the concentration of nickel oxalate is 1.00mol / L, the concentration of magnesium oxalate is 0.01mol / L, and the carrier Immerse in the mixed impregnating solution for 140 minutes, take it out and drain, dry at 130°C for 180 minutes, and roast and decompose at 400°C for 180 minutes, repeat dipping, drying, and roasting once to obtain catalyst B-1. The content of each component, pore structure data, strength data and evaluation data in catalyst B-1 are shown in Table 2.

[0032] Change the addition amount of each component in the above-mentioned preparation process, make catalyst B-2, B-3, B-4, B-5, B-6 re...

Embodiment 3

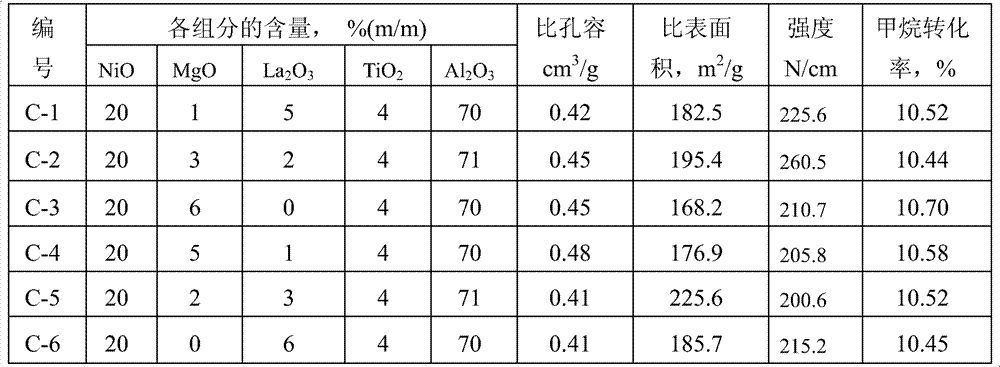

[0036] Weigh 500.0g of alumina powder, add 5.2g of citric acid and 8.6g of turnip powder, add 320mL of water, 20mL of oxalic acid, fully knead, and shape it into a four-leaf clover with an inner diameter of Φ2.0mm and a length of 4.5mm, and roast it at 800°C , to obtain alumina carrier; prepare nickel, lanthanum, magnesium acetate mixed impregnation solution, nickel acetate concentration 1.50mol / L, lanthanum acetate concentration 0.01mol / L, magnesium acetate concentration 0.05mol / L, carrier in the mixed impregnation solution Immerse in water for 140min, take it out and drain, dry at 120°C for 120min, roast and decompose at 400°C for 180min, repeat dipping, drying, and roasting once to obtain catalyst C-1. The content of each component, pore structure data, strength data and evaluation data in catalyst C-1 are shown in Table 3.

[0037] Change the addition amount of each component in the above-mentioned preparation process, make catalyst C-2, C-3, C-4, C-5, C-6 respectively, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com