Anhydrous piperazine preparation method

An anhydrous piperazine and a part of the technology, which is applied in the field of preparation of anhydrous piperazine by catalytic hydrogenation of iminodiacetonitrile, can solve the problems of loss of active components of the catalyst, fast deactivation and short life, and achieve the goal of not being easily deactivated , less by-products, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation of vector

[0041] Carrier 1: Preparation of Mo-ZSM-5 molecular sieve

[0042] Weigh 40g of dried ZSM-5 molecular sieve (silicon-aluminum ratio 30-40); weigh 1.2g of ammonium molybdate, dissolve it in 60ml of pure water, and prepare an ammonium molybdate solution, and pour the solution into the above-mentioned ZSM-5 In molecular sieves, after stirring evenly, let stand for 12 hours, dry at 120°C, and activate at 550°C for 4 hours to obtain modified Mo-ZSM-5 molecular sieves. Through the analysis of the method described above, the highest acid strength on the surface of Mo-ZSM-5 molecular sieve is shown in Table 1.

[0043] Carrier 2: Preparation of Fe-ZSM-5 molecular sieve

[0044] Weigh 40g of dried ZSM-5 molecular sieve (silicon-aluminum ratio 30-40); weigh 4.25g of ferric nitrate nonahydrate, dissolve it in 60ml of pure water, and prepare ferric nitrate impregnation solution, and slowly pour the solution into the above drying In the ZSM-5 molecular sie...

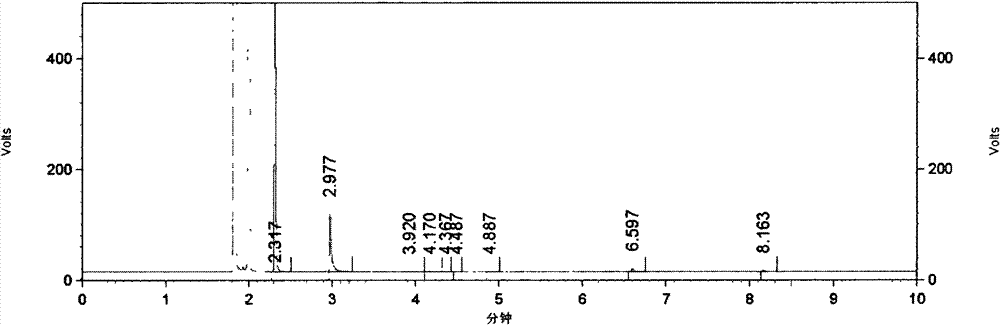

Embodiment 1

[0057] The hydrogenation reactor is a φ25mm×1500mm stainless steel tubular reactor, and the upper part of the reaction tube is filled with 80ml of catalyst 1 with a particle size of 0.6-1mm. The catalyst was reduced at 600° C. for 3 hours with a mixture of hydrogen and nitrogen (volume ratio 1:10) under normal pressure before use.

[0058] Get an appropriate amount of iminodiacetonitrile (IDAN) and 2760ml of tetrahydrofuran (THF) with a water content of 1000ppm and mix them with heat to dissolve. After the measurement, the concentration of IDAN is 22wt%, and it is sent into the reactor at a set speed from the top to keep the addition of IDAN. The amount is 9g / h, and another pipeline is provided to supply 42 standard liters / h of hydrogen. After the raw material is mixed with hydrogen, it enters the bed layer containing the catalyst for hydrogenation-cyclization reaction. The reaction temperature is 75°C, the reaction pressure is 6Mpa, the reaction liquid is collected from the d...

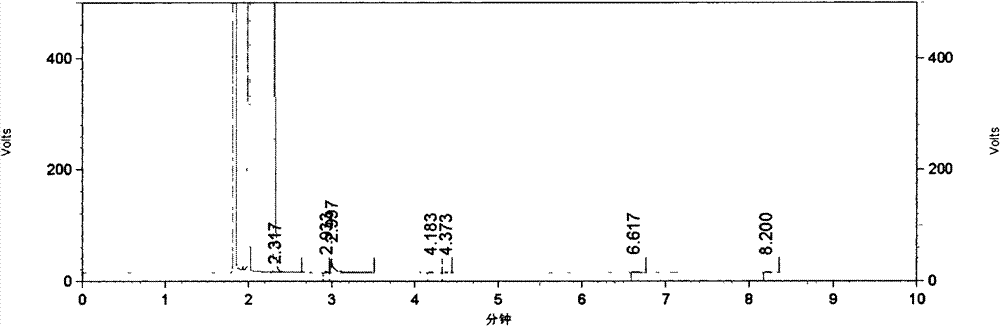

Embodiment 2

[0060] The hydrogenation reactor is a stainless steel tubular reactor with a diameter of φ25mm×1500mm. Take 80ml of catalyst III with a particle size of 0.6-1mm, and fill the bottom of the reaction tube with inert quartz sand. The catalyst was reduced at 600° C. for 3 hours with a mixture of hydrogen and nitrogen (volume ratio 1:10) under normal pressure before use.

[0061] Take an appropriate amount of iminodiacetonitrile (IDAN) and 5500ml of water content is 1% tetrahydrofuran (THF) mixed and then heated to dissolve, IDAN concentration after measurement is 15%, sent into the reactor from the top at a set speed, keep the addition of IDAN The amount is 15g / h, and another pipeline is provided to supply 50.5 standard liters / h of hydrogen. After the raw material is mixed with hydrogen, it enters the bed layer containing the catalyst for hydrogenation-cyclization reaction. The reaction temperature is 90°C, the reaction pressure is 4Mpa, and the reaction liquid is collected from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com