Starch derivative biological latex and preparation method and application thereof

A technology of starch derivatives and bio-latex, applied in the field of bio-latex, can solve the problems of high-concentration starch paste with high viscosity, low bonding strength, and poor fluidity, and achieve easy operation, high solid content, suitable particle size and viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

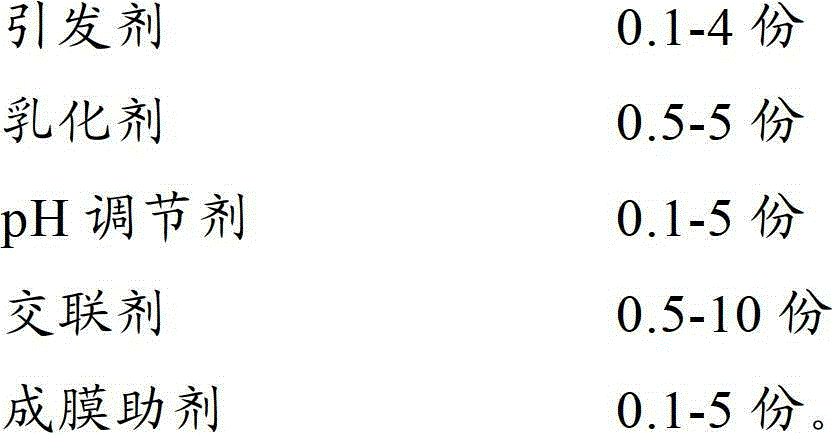

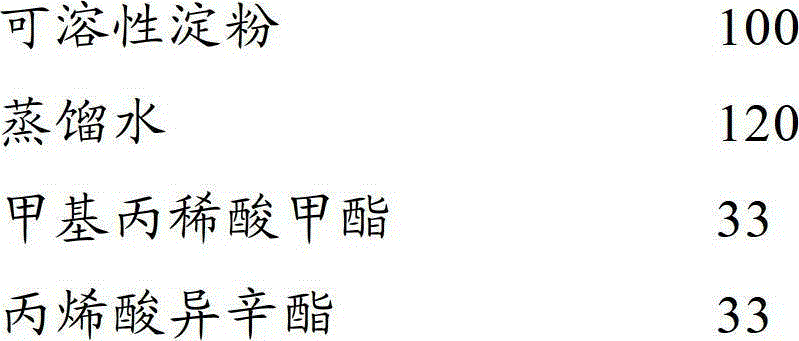

[0024] Formula: (unit g)

[0025]

[0026]

[0027] Preparation Process:

[0028] Add soluble starch and 80% by weight of distilled water to a four-neck flask, heat to 90°C for gelatinization for 30 minutes under nitrogen protection and stirring; cool down to 60°C, add sodium bicarbonate to adjust pH = 7-9; Potassium and sodium dodecylsulfonate are dissolved with 10% by weight of distilled water respectively; ) into the four-neck flask; mix the monomers (ie methyl methacrylate, isooctyl acrylate and ethyl acetate) and the remaining 70% by weight of the initiator solution and divide them into 6 parts evenly, drop every 10 minutes Add once, slowly drop into the reaction kettle, the dropping speed is controlled at about 1 hour; the temperature is controlled at 70°C for grafting reaction for 4 hours, the temperature is lowered to 40°C, and the pH is adjusted to 7-8 to obtain the primary emulsion.

[0029] Heating the primary emulsion prepared above to 55°C, adding sodium t...

Embodiment 2

[0031] Formula: (unit g)

[0032]

[0033] Preparation Process:

[0034] Add soluble starch and 80% by weight of distilled water in a four-neck flask, heat to 85°C for gelatinization for 30 minutes under nitrogen protection and stirring; cool to 70°C, add sodium bicarbonate to adjust pH=7-9; Ammonium sulfate and sodium dodecylsulfonate are dissolved in distilled water with 10% by weight respectively; Add the solution into the four-necked bottle; mix the monomers (ie, methacrylic acid, isooctyl acrylate and methylstyrene) and the remaining 65% by weight of ammonium persulfate solution and divide them into 12 parts, dripping every 10 minutes Add once, slowly drop into the reaction kettle, the dropping speed is controlled at about 2 hours; the temperature is controlled at 70°C for grafting reaction for 4 hours, the temperature is lowered to 45°C, and the pH is adjusted to 7-8 to obtain the primary emulsion.

[0035] Heating the primary emulsion prepared above to 60° C., addi...

Embodiment 3

[0037] Formula: (unit g)

[0038]

[0039] Preparation Process:

[0040] Add maltodextrin and 80% by weight of distilled water to a four-neck flask, heat to 85°C for gelatinization for 30 minutes under nitrogen protection and stirring; cool to 60°C, add sodium bicarbonate to adjust pH=7-9; Ammonium sulfate and OP-10 are dissolved in distilled water with 10% weight respectively; The emulsifier (being OP-10) solution that will configure and the initiator (being ammonium persulfate) solution of 25% weight are added in the four-necked bottle; Monomers (i.e. methacrylic acid, isooctyl acrylate and methyl methacrylate) and the remaining 75% ammonium persulfate solution were mixed and divided into 12 parts on average, added dropwise every 15 minutes, slowly added to In the reaction kettle, the dropping rate is controlled at about 3 hours; the temperature is controlled at 75°C for grafting reaction for 2 hours, the temperature is lowered to 40°C, and the pH is adjusted to 7-8 to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com