Method for removing aluminum from rare earth solution by benzoate precipitation method

A rare earth solution and benzoate technology, applied in the fields of chemical industry, rare earth hydrometallurgy, and chemistry, can solve the problems of large consumption of oxalic acid, high environmental risks, high price of oxalic acid, etc., and achieve full utilization of resources and process operability. The effect of strengthening and eliminating environmental risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

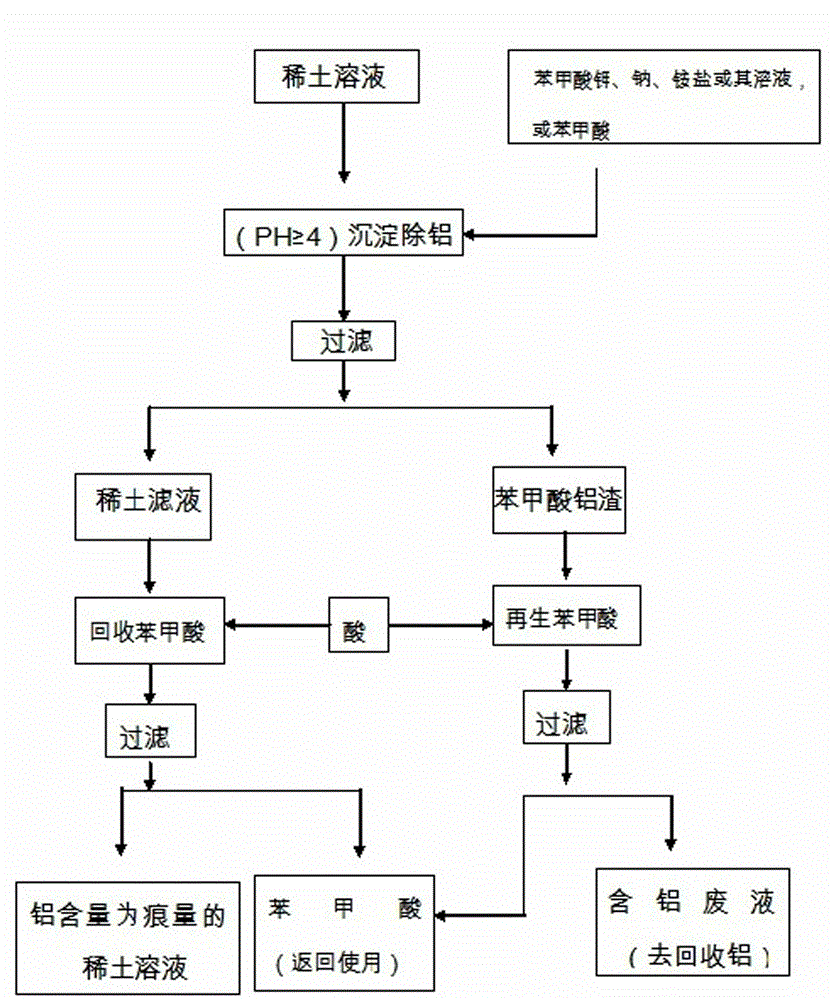

Image

Examples

Embodiment 1

[0030] The embodiment of the present invention 1 benzoate precipitation method from rare earth solution aluminum removal method comprises the following steps:

[0031] (1) Raw material preparation:

[0032] Rare earth solution: praseodymium and neodymium chloride solution produced by extraction and separation: the rare earth content is Pr 6 o 11 +Nd 2 o 3 200g / l, PH4, 20m 3 .

[0033] Precipitating agent: industrial grade sodium benzoate, according to 130% of the theoretical reaction volume, prepare 265kg.

[0034] (2) Aluminum removal by precipitation:

[0035] Under stirring in the rare earth solution, add 265 kg of sodium benzoate, continue to stir for 30 minutes to make the reaction fully, let stand for 1 to 2 hours, separate and filter to obtain aluminum benzoate slag and praseodymium neodymium chloride filtrate with trace amounts of aluminum.

[0036] The obtained praseodymium-neodymium chloride filtrate of embodiment 1 is processed and reclaimed benzoic acid: the...

Embodiment 2

[0039] The embodiment of the present invention 2 benzoate precipitation method from the rare earth solution aluminum removal method comprises the following steps:

[0040] (1) Raw material preparation:

[0041] The rare earth solution is the yttrium chloride solution produced by extraction and separation: the rare earth content Y 2 o 3 180g / l, Al 2 o 3 2g / l, PH4, 10m 3 .

[0042] Precipitant: Prepare 180 kg of benzoic acid according to 120% of the theoretical reaction volume, dissolve 180 kg of benzoic acid with 6% ammonia water to pH 7-8, and wait for complete dissolution to obtain ammonium benzoate solution.

[0043] (2) Aluminum removal by precipitation:

[0044] Under stirring in the yttrium chloride solution, add the ammonium benzoate solution prepared in step (1), stir for 30 minutes to make the reaction fully, stand for 2 hours, separate and filter to obtain aluminum benzoate slag and yttrium chloride rare earth filtrate.

[0045] (3) Recovery of benzoic acid

[0...

Embodiment 3

[0051] The embodiment of the present invention 3 benzoate precipitation method from the rare earth solution aluminum removal method comprises the following steps:

[0052] (1) Raw material preparation:

[0053] The rare earth solution is a neodymium chloride solution produced by extraction and separation: the rare earth content Nd 2 o 3 200g / l, Al 2 o 3 2g / l, PH4, 10m 3 .

[0054] Precipitant: Prepare 180kg of benzoic acid according to 120% of the theoretical reaction volume

[0055] (2) Aluminum removal by precipitation:

[0056] Under stirring in the yttrium chloride solution, slowly add the benzoic acid in step (1), and at the same time add a small amount of ammonia water to adjust the pH to 4.5, continue to stir for 30 minutes to make the reaction fully, stand for 2 hours, separate and filter to obtain aluminum benzoate slag and chlorine Neodymium Rare Earth Filtrate.

[0057] (3) Recovery of benzoic acid

[0058] Add a small amount of hydrochloric acid to the rar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com