High-temperature-resistant soft double-shield instrument cable for maritime oil and gas engineering and manufacturing method thereof

A technology for instrument cables and high temperature resistance, which is applied in the direction of cable/conductor manufacturing, insulated cables, and bendable cables, etc. Corrosion, not suitable for insulating materials and other problems, to achieve excellent anti-seawater corrosion performance, avoid melting dripping, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

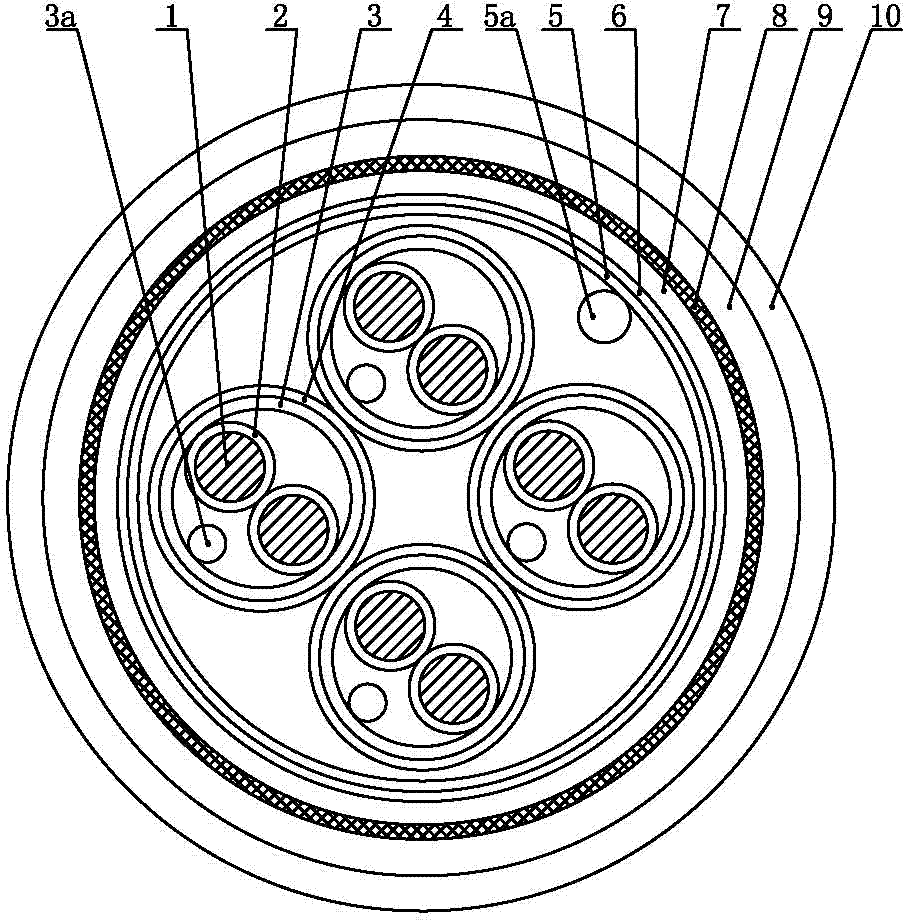

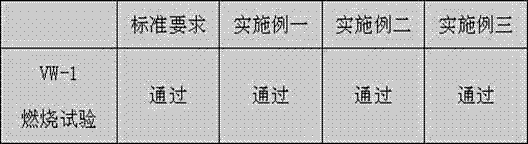

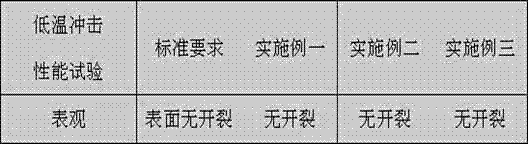

[0023] Such as figure 1 As shown, the high-temperature-resistant soft double-shielded instrument cable for offshore oil and gas engineering of the present invention is manufactured according to the following steps: extruding a chemically cross-linked polyolefin insulating layer 2 on the periphery of a tinned annealed stranded copper conductor 1 of 0.35 mm to form an insulating core , the insulated wire cores are twisted in pairs to form a pair of twisted wires, the twisted pitch of each pair of twisted wires is not greater than 120mm and all pairs of twisted wires use different twisted pitches; each pair of twisted wires The outer circumference of the wrapped wire core copper foil polyester composite tape shielding layer 3 and the copper foil faces inward, the inner side of the core copper foil polyester composite tape shielding layer 3 is provided with a core tinned stranded copper wire drainage wire 3a, the wire core is plated Tin stranded copper wire drainage wire 3a runs t...

Embodiment 2

[0029] The high-temperature-resistant soft double-shielded instrument cable for offshore oil and gas engineering of the present invention is manufactured according to the following steps: a chemically cross-linked polyolefin insulating layer 2 is extruded on the outer periphery of a tinned annealed stranded copper conductor 1 of 1.25mm2 to form an insulating core, and an insulating wire The cores are twisted in pairs to form a pair of twisted wires. The twisted pitch of each pair of twisted wires is not greater than 120mm and all pairs of twisted wires adopt different twisted pitches; the outer circumference of each pair of twisted wires is wound Covered wire core copper foil polyester composite tape shielding layer 3 and the copper foil faces inward, the inner side of the wire core copper foil polyester composite tape shielding layer 3 is provided with a tinned stranded copper wire drain wire 3a, the wire core is tinned and stranded The copper wire drainage wire 3a runs throug...

Embodiment 3

[0035] The high-temperature-resistant soft double-shielded instrument cable for offshore oil and gas engineering of the present invention is manufactured according to the following steps: extruding a chemically cross-linked polyolefin insulating layer 2 on the outer periphery of a tinned annealed stranded copper conductor 1 of 2.5mm2 to form an insulating core, an insulating wire The cores are twisted in pairs to form a pair of twisted wires. The twisted pitch of each pair of twisted wires is not greater than 120mm and all pairs of twisted wires adopt different twisted pitches; the outer circumference of each pair of twisted wires is wound Covered wire core copper foil polyester composite tape shielding layer 3 and the copper foil faces inward, the inner side of the wire core copper foil polyester composite tape shielding layer 3 is provided with a tinned stranded copper wire drain wire 3a, the wire core is tinned and stranded The copper wire drainage wire 3a runs through the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com