Method for extracting sulfur and inorganic salt from wet-desulfurization waste sulfur paste

A sulfur paste, sulfur technology, applied in chemical instruments and methods, thiosulfate/dithionite/polythionate, inorganic chemistry, etc., can solve the need for sewage discharge, large equipment investment, complex operation, etc. problem, to achieve the effect of strong fluctuation adaptability, high purity and high extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

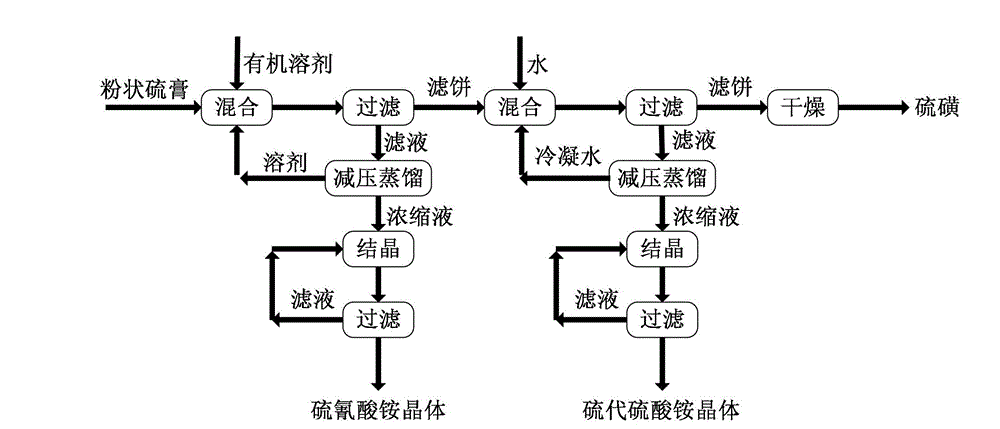

Image

Examples

Embodiment 1

[0020] A method for extracting sulfur and inorganic salts from wet desulfurization waste sulfur paste, comprising the steps of:

[0021] (1) Take 100g of powdered sulfur paste obtained by spray drying (containing about 24.8% sulfur, about 43.6% ammonium thiosulfate, about 31.6% ammonium thiocyanate) into a 500ml three-necked bottle, add methanol and acetone Mixed solution 100g (wherein the mass fraction of methanol is 85%, the mass fraction of acetone is 15%), stir at room temperature for 1h, filter and wash the filter cake with 20g of the above organic solvent, filter, the obtained filtrate is ammonium thiocyanate solution, filter cake It is a mixture of sulfur, ammonium thiosulfate and other insoluble impurities. After the filtrate is decolorized and distilled under reduced pressure, the temperature is controlled below 80°C, the distillation pressure is controlled below 10kPa (absolute pressure), and 100g of solvent is evaporated to obtain a concentrated solution. 98%, the ...

Embodiment 2

[0026] A method for extracting sulfur and inorganic salts from wet desulfurization waste sulfur paste, comprising the steps of:

[0027] (1) Take 200g of spray-dried powdered sulfur paste (containing about 22.5% sulfur, about 45.2% ammonium thiosulfate, and about 32.3% ammonium thiocyanate) into a 1000ml three-necked bottle, add 250g methanol, and stir at room temperature 45min, filter and wash the filter cake with 40g methanol, filter, the filtrate obtained is the methanol solution of ammonium thiocyanate, the filter cake is the mixture of sulfur, ammonium thiosulfate and other insoluble impurities, the filtrate is distilled under reduced pressure, and the temperature is controlled at 80 Below ℃, the distillation pressure is controlled below 10kPa (absolute pressure), and 200g of solvent is distilled to obtain a concentrated solution. The concentrated solution is cooled and crystallized, and 65.4g of ammonium thiocyanate crystals are obtained by filtration, with a content of 9...

Embodiment 3

[0031] A method for extracting sulfur and inorganic salts from wet desulfurization waste sulfur paste, comprising the steps of:

[0032] (1) Extract ammonium thiocyanate: Mix 100g of dried powdered sulfur paste with 90g of methanol and acetone mixed solution (85% by mass of methanol and 15% by mass of acetone), and stir at room temperature for 0.5 h, filter, wash the solid with 20g of the above solvent, filter to obtain the filtrate and filter cake, combine the filtrate, decolorize the filtrate, distill under reduced pressure below 80°C, distill 90 parts by mass of organic solvent to obtain a concentrated solution, and the concentrated solution crystallizes on cooling , filtered to obtain ammonium thiocyanate crystals (29.5g, content of 97.5%) and mother liquor, the mother liquor was reused in the crystallization process;

[0033] (2) Separation of sulfur and ammonium thiosulfate: dry the filter cake, mix with water equivalent to 90% of the mass of the filter cake, stir at roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com