Fried peas with low breakage rate and high sensory quality and production process thereof

A technology of production process and crushing rate, applied in the field of fried peas and its production process, can solve the problems of reducing economic benefit, influence of appearance and taste sensory quality, crushing, etc., and achieves simple production process, good comprehensive sensory quality, and finished product. high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

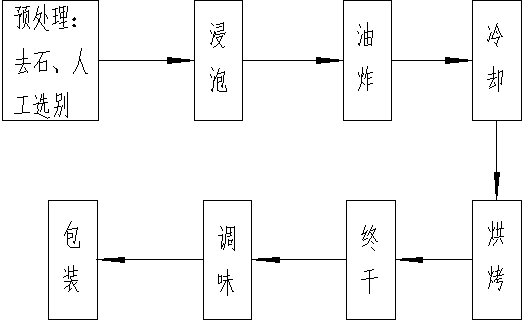

[0025] A production process of fried peas with low broken rate and good sensory quality, such as figure 1 shown, including the following steps:

[0026] (1) Pre-treatment: Peas are stone-removed and manually sorted to select peas with full grains, uniform size, no mildew, no damage, no insects, diseases, spots, yellow skin, old beans, and shriveled beans.

[0027] (2) Soaking: Weigh 1000g of the pre-treated peas with an electronic balance, put them in a constant temperature incubator and soak them in water at 20°C for 8 hours, so that the peas can fully absorb water and swell, and the water content in the peas can reach 55% by weight.

[0028] (2) Frying: Put the soaked peas above into a fryer with edible oil and fry them at a temperature of 165°C, a feeding frequency of 339.0Hz, and a time of 480s, so that the water content of the peas is reduced to a minimum by weight fraction. at 2.5%.

[0029] (3) Post-processing: The above-mentioned fried peas are subjected to the follo...

Embodiment 2

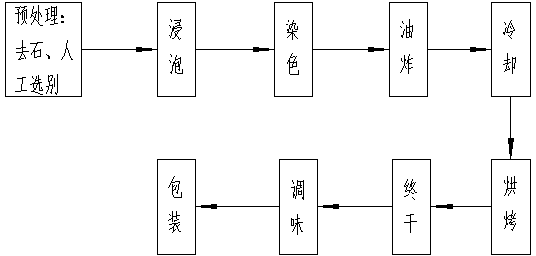

[0043] A production process of fried peas with low broken rate and good sensory quality, such as figure 2 As shown, the difference from Example 1 is that the peas are dyed with a dyeing agent after the soaking step and before the frying step. Since the bright green color of peas produced in soaking will be altered in frying, losing the covering of high concentration of chlorophyll, the green color will be covered by yellow or orange pigment, and the peas will take on an olive green appearance, so by proper dyeing to give peas better appearance. During the dyeing process, it is necessary to check the dyeing situation in due course. The method is: split the peas. If the inside and outside of the peas are observed to have the same color and no hard core, it can be considered that the dyeing is complete. It is also very important to judge the dyeing uniformity of peas. The inventor’s judgment on the dyeing uniformity in the production process is based on: extract 500g of dyed pe...

Embodiment 3

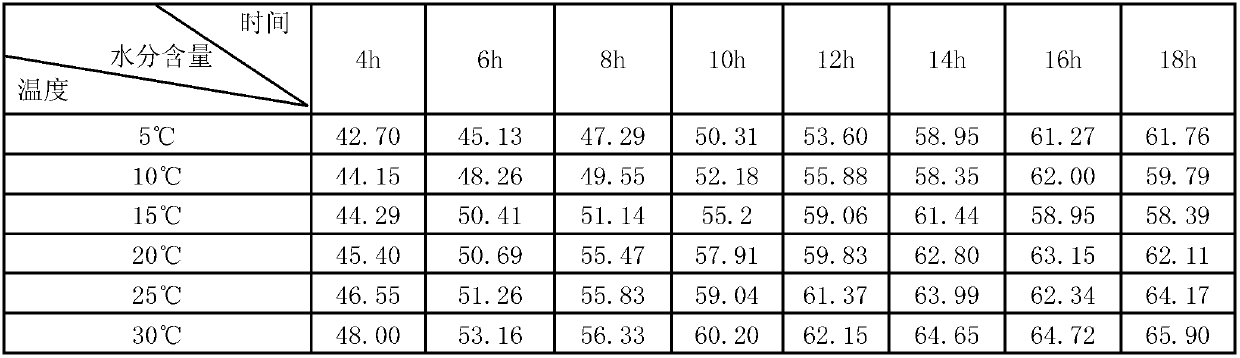

[0050] A production process of fried peas with low breakage rate and good sensory quality, the difference from Example 1 lies in: soaking temperature, soaking time, moisture content, frying temperature and feeding frequency, see Table 5 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com