Method for preparing tanshinone IIA sodium sulfonate preparation by using hydrotropic defoaming solvent

A technology of sodium sulfonate and tanshinone, which is applied in the field of preparation of tanshinone IIA sodium sulfonate injection, can solve the problems of uneven appearance of freeze-dried preparations, impossibility of industrial production, and difficult elimination of air bubbles, etc., to improve sublimation rate, facilitate sublimation, and low toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

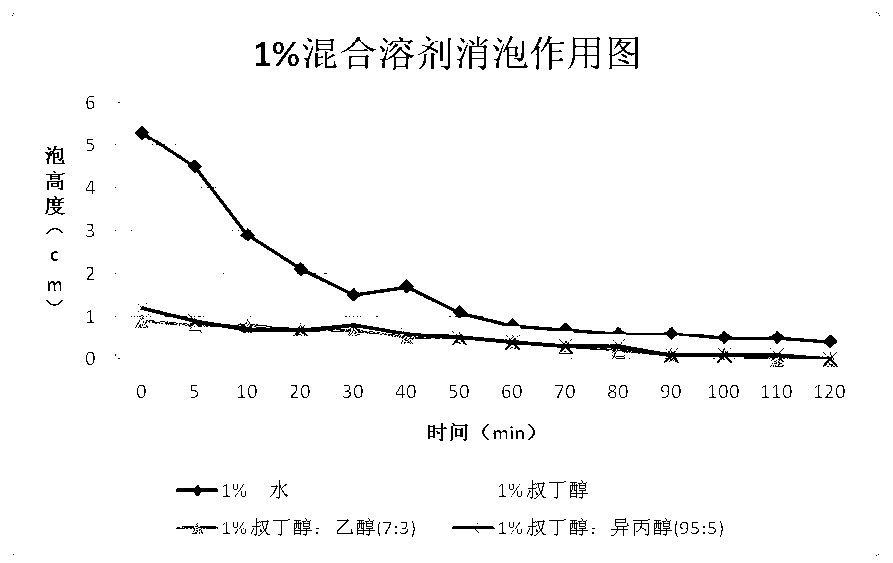

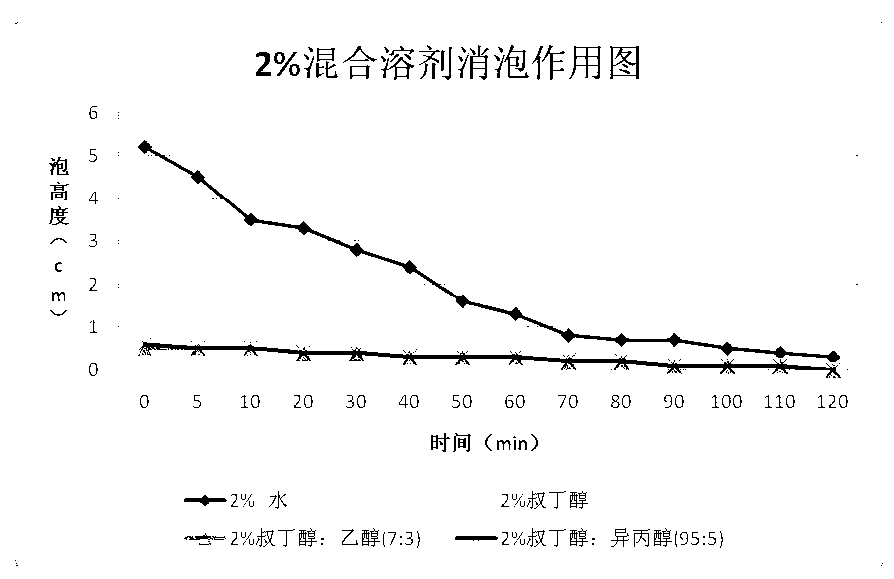

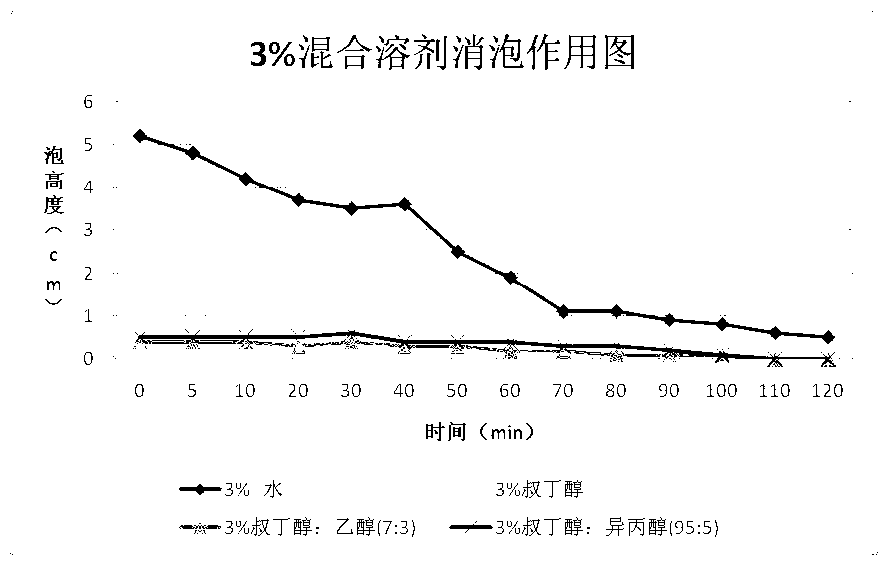

Image

Examples

Embodiment 1

[0022] Embodiment one: provide a kind of method that adopts solvent to prepare tanshinone IIA sodium sulfonate injection, Measure 50ml of tert-butanol: isopropanol as a 95:5 mixed solvent and measure 4L of water for injection (room temperature) into the batching tank, stir and dissolve for 10 minutes, add 20g of sodium tanshinone ⅡA sulfonate under dark conditions, and stir until completely dissolved;

[0023] Add 250g of mannitol, stir to dissolve completely, add water for injection to 5L;

[0024] Add activated carbon of 0.05% (W / V) volume of the liquid medicine and stir for 15 minutes, and decarbonize the titanium filter rod;

[0025] Use 0.05mol / L hydrochloric acid solution or 0.05mol / L sodium hydroxide solution to adjust the pH to be between 5.0 and 6.5, and no adjustment is required within this range;

[0026] Detect the intermediate, and filter it with a 0.22 μm microporous membrane after passing the test;

[0027] Filling into antibiotic bottles;

[0028...

Embodiment 2

[0030] Embodiment two: provide a kind of method that adopts solvent to prepare tanshinone IIA sodium sulfonate injection, Measure 50ml of tert-butanol:ethanol mixed solvent of 70:30 and 8L water for injection (room temperature) into the batching tank, stir and dissolve for 10 minutes, add 40g of sodium tanshinone ⅡA sulfonate under dark conditions, stir until dissolved completely;

[0031] Add 500g of mannitol, stir to dissolve completely, add water for injection to 10L;

[0032] Add activated carbon of 0.05% (W / V) volume of the liquid medicine and stir for 15 minutes, and decarbonize the titanium filter rod;

[0033] Use 0.05mol / L hydrochloric acid solution or 0.05mol / L sodium hydroxide solution to adjust the pH between 5.0 and 6.5;

[0034] Detect the intermediate, and filter it with a 0.22 μm microporous membrane after passing the test;

[0035] Filling into antibiotic bottles;

[0036] Place the sample in a freeze dryer, pre-freeze, sublimate, keep warm, a...

Embodiment 3

[0038] Embodiment three: provide a kind of method that adopts solvent to prepare tanshinone IIA sodium sulfonate injection, comprise the steps:

[0039] Measure 40-50ml of a single tert-butanol solvent and 8L of water for injection (at room temperature) into the batching tank, stir and dissolve for 10 minutes, add 40g of sodium tanshinone IIA sulfonate under dark conditions, and stir until completely dissolved;

[0040] Add 500g of mannitol, stir to dissolve completely, add water for injection to 10L;

[0041] Add activated carbon of 0.05% (W / V) volume of the liquid medicine and stir for 15 minutes, and decarbonize the titanium filter rod;

[0042] Use 0.05mol / L hydrochloric acid solution or 0.05mol / L sodium hydroxide solution to adjust the pH between 5.0 and 6.5;

[0043] Detect the intermediate, and filter it with a 0.22 μm microporous membrane after passing the test;

[0044] Filling into antibiotic bottles;

[0045] Place the sample in a freeze dryer, pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com