Preparation method and process for antibacterial modification of ceramic whiskers

A ceramic whisker and modification technology, which can be applied in the direction of local antibacterial agents, resistance to vector-borne diseases, medical preparations containing active ingredients, etc., can solve the problems of insignificant enhancement and inability to increase material strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation method of the present invention:

[0030] A. Dissolve the zinc salt and complex compound with a mass ratio of 1:0 to 4:1 in absolute ethanol with stirring at 70°C to make a clear solution with a concentration of 0.04 to 0.08mol / L. This product is I;

[0031] B. The hydroxyapatite whiskers are evenly dispersed in the ethanol solution by ultrasonic vibration, and the product is II;

[0032] C. Under stirring, slowly add the product I dropwise to the product II, adjust the pH value to 4.8-8.2 with ammonia water, react at a constant temperature of 37°C-70°C for 4-8 hours, and then sonicate for 10-60 seconds; heat up to Evaporate the solvent to dryness at 78°C to 80°C, and place it in a thermostat to dry completely. The product is III;

[0033] D. Put the product III in an airtight container to roast, raise the temperature to 800°C-900°C at a rate of 2-5°C / min and keep it warm for 0.5-2 hours, then slowly cool down to room temperature with the container to obtai...

Embodiment 1

[0038] A. Dissolve zinc acetate in absolute ethanol with stirring at 70°C to make a clear solution with a concentration of 0.06mol / L;

[0039] B. Hydroxyapatite whiskers are evenly dispersed in ethanol solution by ultrasonic vibration;

[0040] C. Under stirring, slowly add the clear solution formed in step A into the dispersion formed in step B, adjust the pH to 4.8 with ammonia water, react at a constant temperature of 37°C for 6 hours, then ultrasonicate for 15 seconds, and raise the temperature to 78°C-80°C Evaporate the solvent to dryness at ℃, and place it in a constant temperature box to dry completely; put the product in a closed container and roast at a heating rate of 2°C to 5°C to 800°C and keep it warm for 1 hour, then slowly cool down to room temperature with the container, and a well-modified product is obtained. ZnO-hydroxyapatite whiskers.

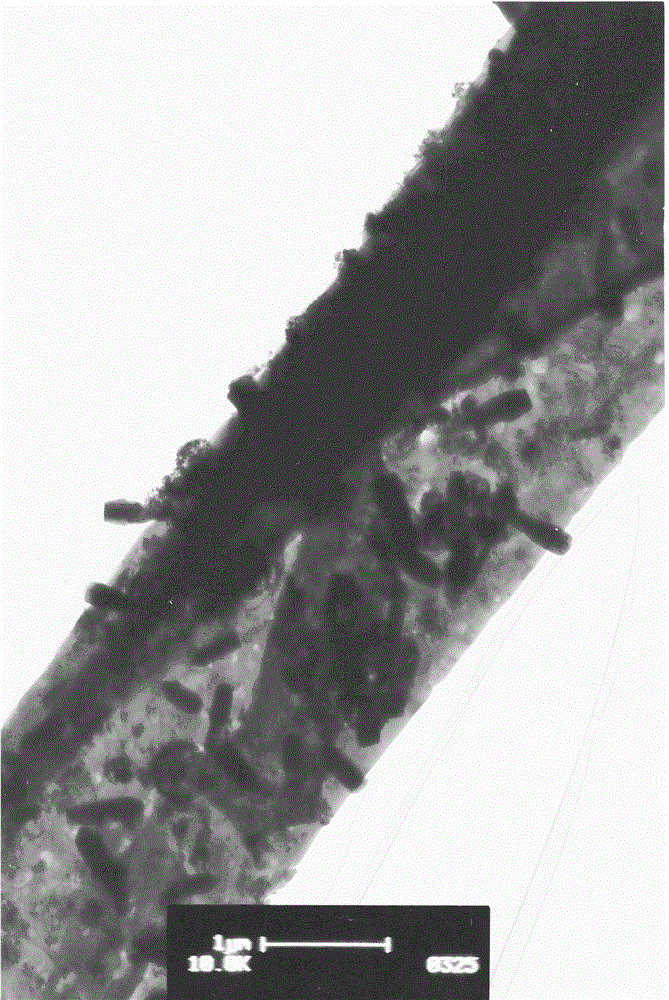

[0041] The results of transmission electron microscopy analysis are shown in figure 1 , a small amount of zinc oxide ba...

Embodiment 2

[0043] A. Dissolve zinc acetate in absolute ethanol with stirring at 70°C to make a clear solution with a concentration of 0.06mol / L;

[0044] B. Hydroxyapatite whiskers are evenly dispersed in ethanol solution by ultrasonic vibration;

[0045] C. Under stirring, slowly drop the clear liquid formed in step A into the dispersion liquid formed in step B, adjust the pH to 6.4 with ammonia water, react at a constant temperature of 37°C for 6 hours, then ultrasonicate for 15 seconds, and raise the temperature to 78°C-80°C Evaporate the solvent to dryness at ℃, and place it in a constant temperature box to dry completely; put the product in a closed container and roast at a heating rate of 2°C to 5°C to 800°C and keep it warm for 1 hour, then slowly cool down to room temperature with the container, and a well-modified product is obtained. ZnO-hydroxyapatite whiskers.

[0046] The results of transmission electron microscopy analysis are shown in figure 2 , the measured diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com