Sound insulation noise reduction wall paper and preparation method thereof

A technology of noise reduction and wallpaper, applied in ceramic products, other household appliances, applications, etc., can solve the problems of dust pollution, reduced sound absorption effect, poor adhesion of sound absorption media, etc., and achieve excellent broadband sound absorption and noise reduction, high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

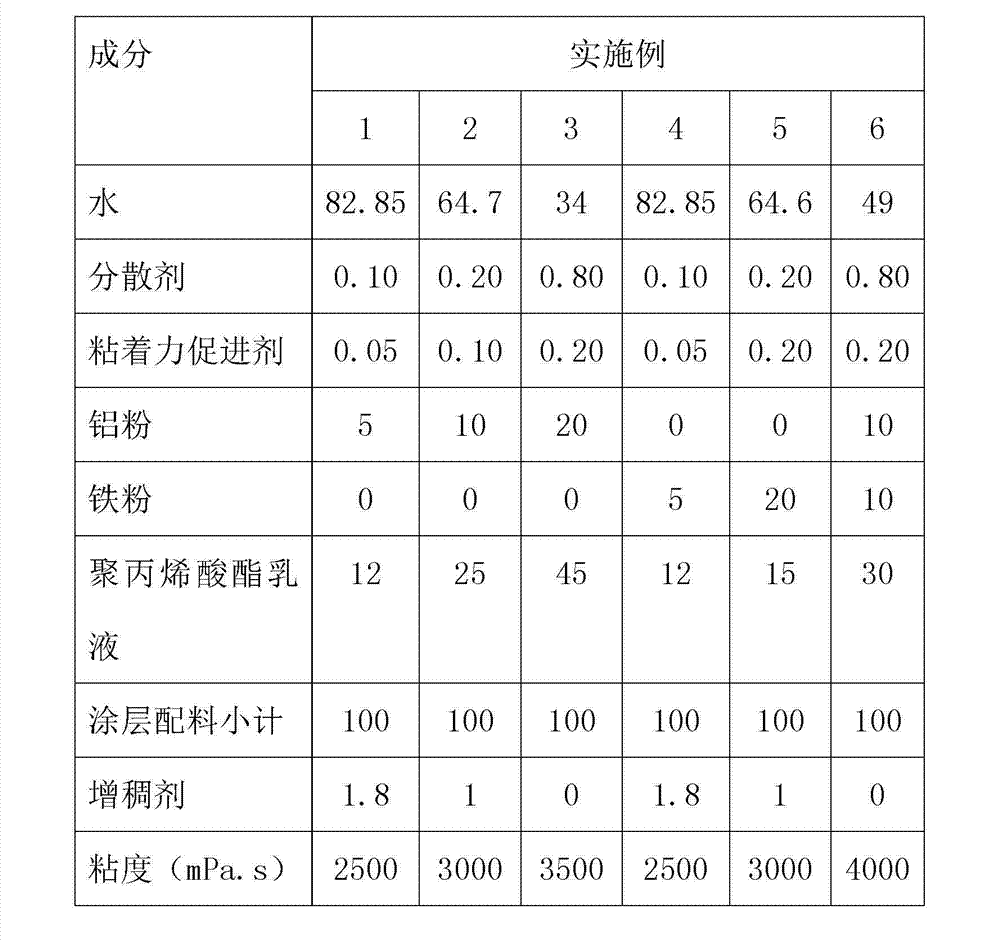

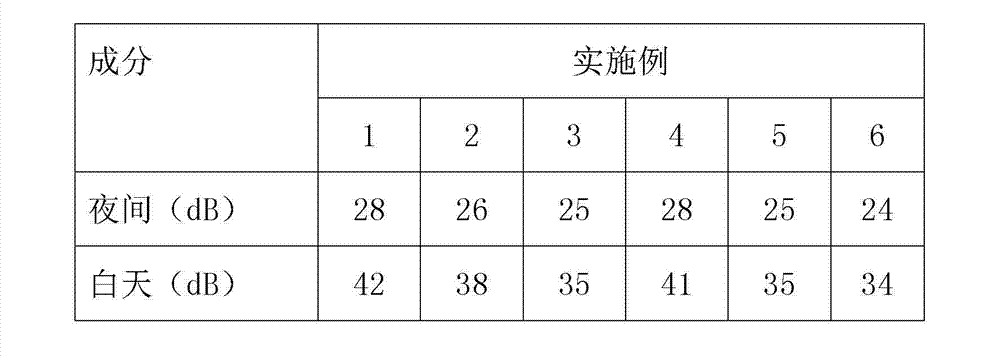

Embodiment 1

[0032] A sound-insulating and noise-reducing wallpaper comprises a base material, a sound-insulating and noise-reducing coating on the base material, and a printing layer printed on the sound-insulating and noise-reducing coating.

[0033]The base material can be: "a modified polyolefin paper without plant fiber" applied by our company, Chinese patent, ZL200810190942.5). The characteristics of the substrate are: calcium carbonate content 75% and polyethylene content 25%, the thickness is 100 microns, the width is 500 mm, and the specific gravity is 0.85 g / cm 3 , the whiteness is 65.

[0034] The sound-insulating and noise-reducing coating includes 12% water-based latex, 0.1% dispersant, 0.05% adhesion promoter, 5% aluminum powder and 82.85% deionized water.

[0035] The thickener is polyurethane thickener SN-612, and the thickener is 1.8% of the mass of the sound insulation and noise reduction coating.

[0036] The water-based latex is polyacrylate emulsion.

[0037] The di...

Embodiment 2

[0048] A sound-proof and noise-reducing wallpaper, which differs from Embodiment 1 in that:

[0049] The sound-insulating and noise-reducing coating includes 25% water-based latex, 0.20% dispersant, 0.10% adhesion promoter, 10% aluminum powder and 64.7% deionized water.

[0050] The thickener is polyurethane thickener DT-105, and the thickener is 1% of the mass of the sound insulation and noise reduction coating.

[0051] The water-based emulsion in the sound-insulating and noise-reducing coating is polyacrylate emulsion.

[0052] The dispersant is sodium hexametaphosphate.

[0053] The adhesion promoter is TECH adhesion promoter Adhesion Promoters (Shanghai Tiger Polymer Technology Co., Ltd.).

[0054] The aluminum powder is 2000 mesh.

[0055] A preparation method for sound-proof and noise-reducing wallpaper, comprising the following steps:

[0056] The first step is to select the base material, "a modified polyolefin paper without plant fiber".

[0057] In the second s...

Embodiment 3

[0062] A sound-insulating and noise-reducing wallpaper comprises a base material, a sound-insulating and noise-reducing coating on the base material, and a printing layer printed on the sound-insulating and noise-reducing coating.

[0063] The base material can be "inorganic powder highly filled polyolefin decorative paper and its manufacturing method" (Chinese patent, CN102085736 A). The characteristics of the substrate are: calcium carbonate content 85%, calcium silicate content 5% and polyethylene content 10%, thickness 400 microns, width 2500 mm, specific gravity 1.5 g / cm 3 , the whiteness is 95.

[0064] The sound-insulating and noise-reducing coating comprises 45% of water-based latex, 0.8% of dispersant, 0.2% of adhesion promoter, 20% of aluminum powder and 34% of deionized water.

[0065] The water-based emulsion in the sound-insulating and noise-reducing coating is polyacrylate emulsion.

[0066] The dispersant is sodium pyrophosphate.

[0067] The adhesion promote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com