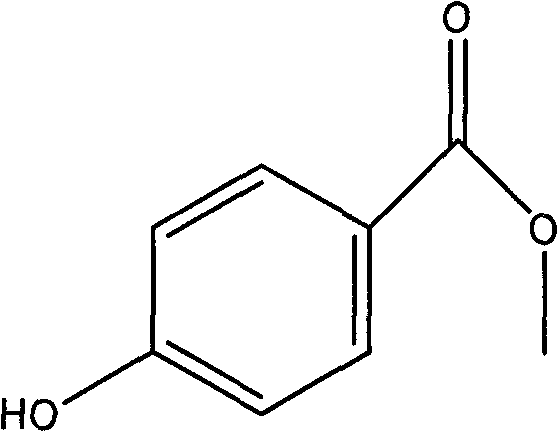

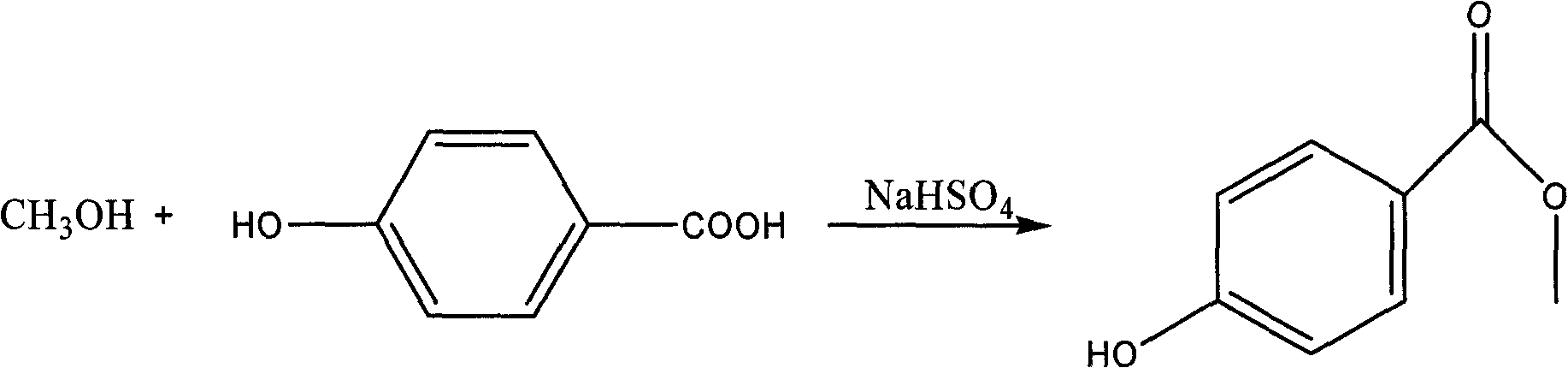

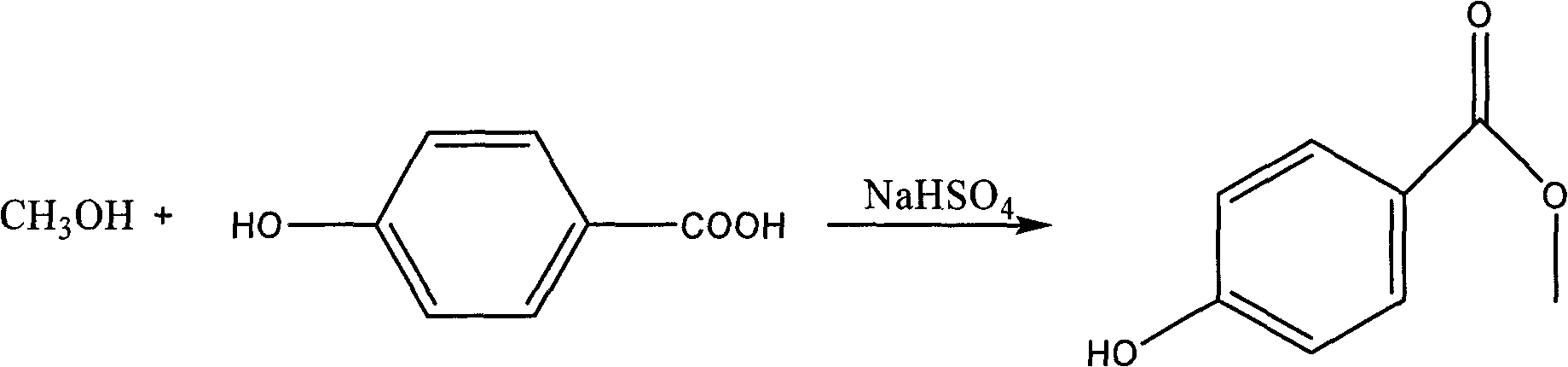

Synthesis process of methylparaben

A technology for the synthesis of methyl paraben esters, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, and organic chemistry. It can solve problems such as poor product quality, long reaction time, and waste liquid corrosion of equipment, and achieve stable properties. , Simple operation, short time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The process steps of the present invention are: adding p-hydroxybenzoic acid and methanol with a molar ratio of 1: 1.5 to 1: 4.0 in a round bottom flask, and then adding 0.1 to 0.6 g / g of catalyst sodium bisulfate; placing the flask in a cavity of a microwave oven In the process, the flask is connected to the external stirring and water separating and condensing device through the three-port connecting pipe placed at the hole on the top of the microwave oven; preheat to dissolve the raw materials, and after the dissolution, adjust the microwave output power to 450W to continue heating. When the water separator starts Start timing when the distillate appears; after reacting for 3 to 18 minutes, pour out the reaction solution, and the catalyst remains in the flask as a solid; distill the reaction solution to remove excess methanol, and pour 5% sodium bicarbonate into it while it is hot Aqueous solution, the ester is separated from the water; the crude ester is obtained by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com