Conjugated polymer gelling agent poly(phenylene ethynylene) and preparation method thereof

A technology of conjugated polymers and polyphenylene acetylene, applied in the field of supramolecular self-assembly and gel materials, can solve problems such as not too clear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

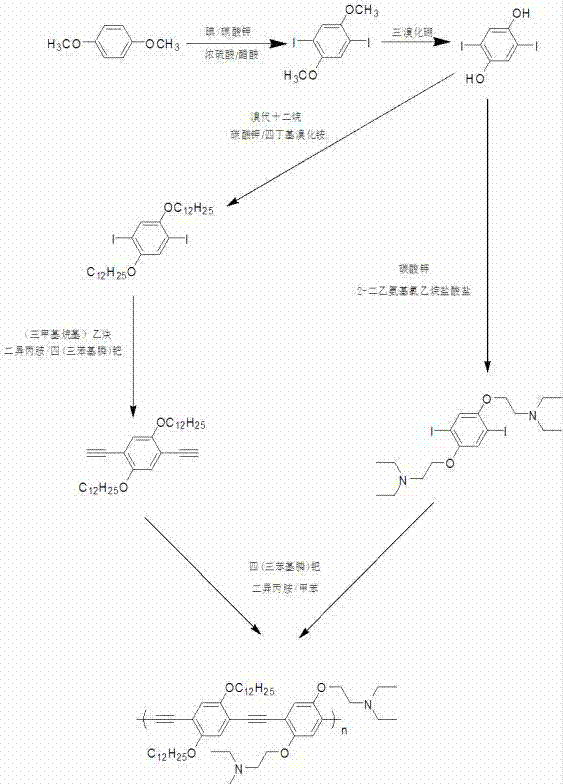

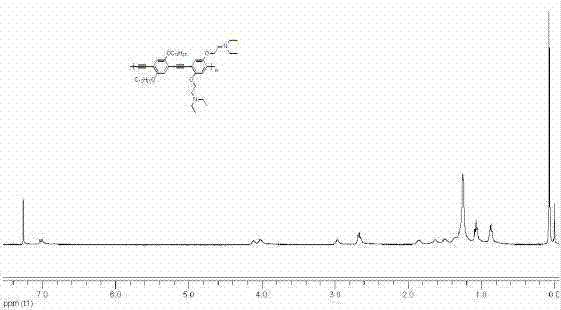

[0034] Embodiment 1, the synthesis of novel conjugated polymer gelling agent polyphenylene acetylene, synthetic route diagram is as follows figure 1 shown.

[0035]

[0036] (1) Synthesis of 1,4-diiodo-2,5-benzenediol:

[0037] Synthesis of 1,4-dimethoxy-2,5-diiodobenzene: 13.9 g (100.7 mmol) of 1,4-dimethoxybenzene, 8.8 g (8 mmol) of potassium iodate and 28.3 g of iodine ( 112.3 mmol) was dissolved in 500 ml of pure acetic acid, then 50 ml of water and 5 ml of concentrated sulfuric acid were added, and stirred at 85 °C for 24 hours, and the reaction was protected from light, and precipitation occurred during the reaction. After cooling to room temperature, the precipitate was collected by suction filtration, and the solid was neutralized by washing with a large amount of potassium carbonate solution and water to obtain a brown solid primary product, which was then dissolved with a large amount of dichloromethane and extracted with aqueous sodium bisulfite solution. Afte...

Embodiment 2

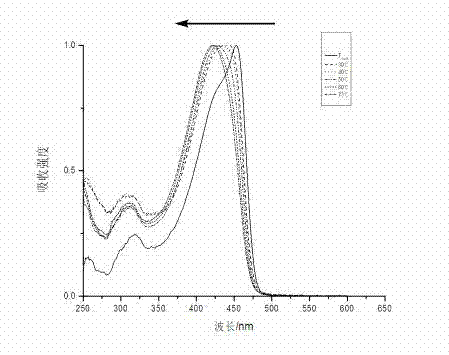

[0057] Embodiment 2, the method for preparing gel by novel conjugated polymer gelling agent polyphenylene acetylene

[0058] Generally, the preparation of gels generally adopts the "heating-cooling method", and is generally temperature-sensitive and reproducible. Unlike common preparation methods, the preparation of the gel does not require heating, and a good solvent and a poor solvent are directly mixed to prepare the gel. The gel is soluble in acetic acid, dichloromethane, tetrahydrofuran and other organic solvents, and insoluble in water, methanol, acetone and other solvents. Mix acetic acid and water in a certain volume ratio, put a certain amount of gel, and stand at room temperature. More than 12 hours, without heating, the formation of gel can be found. The experiment found that the volume ratio of acetic acid and water is between 1 / 2 and 1 / 2.5, the limit gel concentration is about 9mg / ml, and the gel-solution conversion The temperature is about 52°C.

[0059] Mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com