Method for preparing bio-ethanol with suaeda salsa as raw material

A technology of bioethanol and Suaeda salsa, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as inconsistency in the optimum action temperature, achieve short production cycles, improve synchronous saccharification and fermentation efficiency, and ethanol output Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The application of embodiment 1 normal temperature cellulase

[0030] A method for preparing bioethanol with Suaeda salsa as raw material, the specific steps are as follows:

[0031] (1) Pre-treatment of Suaeda salsa stalks: ① Collect dead stalks of Suaeda salsa and remove impurities; ② Dry the stalks after ① removal of impurities; The diameter is 0.45-0.9mm;

[0032] (2) Pretreatment of Suaeda stalk: mix 800g of the treated stalk with 0.7% (w / w) sodium hydroxide solution at a solid-liquid ratio of 1:15 (g / ml), Treat at 110°C for 10 minutes;

[0033] (3) Preparation of Suaeda stalk fermentation medium: Adjust the pH value of the pretreated Suaeda stalk feed liquid to 5.0, and add yeast powder with a final concentration (w / v) of 0.3%, 0.5% peptone, 0.02% urea, 0.4% magnesium sulfate, 0.01% diammonium phosphate;

[0034] (4) Simultaneous saccharification and fermentation to produce ethanol: add 8% high-activity Saccharomyces cerevisiae with a mass ratio of 8% to the f...

Embodiment 2

[0037] Application of embodiment 2 Antarctic low temperature cellulase

[0038] A method for preparing bioethanol with Suaeda salsa as raw material, the specific steps are as follows:

[0039] (1) Pre-treatment of Suaeda stalks: ① Collect dried stalks and remove impurities; ② Dry ① the stalks after removal of impurities; ③ Grind the stalks after treatment to particle size 0.45—0.9mm;

[0040] (2) Pretreatment of Suaeda stalk: mix 800g of the treated stalk with 0.7% (w / w) sodium hydroxide solution at a solid-liquid ratio of 1:15 (g / ml), Treat at 110°C for 10 minutes;

[0041] (3) Preparation of Antarctic low-temperature enzyme: ① Inoculate and activate the Antarctic low-temperature bacterial strain QP7 screened from Antarctic soil samples preserved in the laboratory; In the enzyme medium, the medium consists of (NH4) 2 SO 4 0.5% (g / ml), MgSO 4 0.02% (g / ml), bran 3% (g / ml), cultured on a low-temperature shaker at 150rpm, 15°C for 4 days; ③ Centrifuge the QP7 enzyme-producing...

Embodiment 3

[0046] Example 3 Combined application of low temperature cellulase and normal temperature cellulase

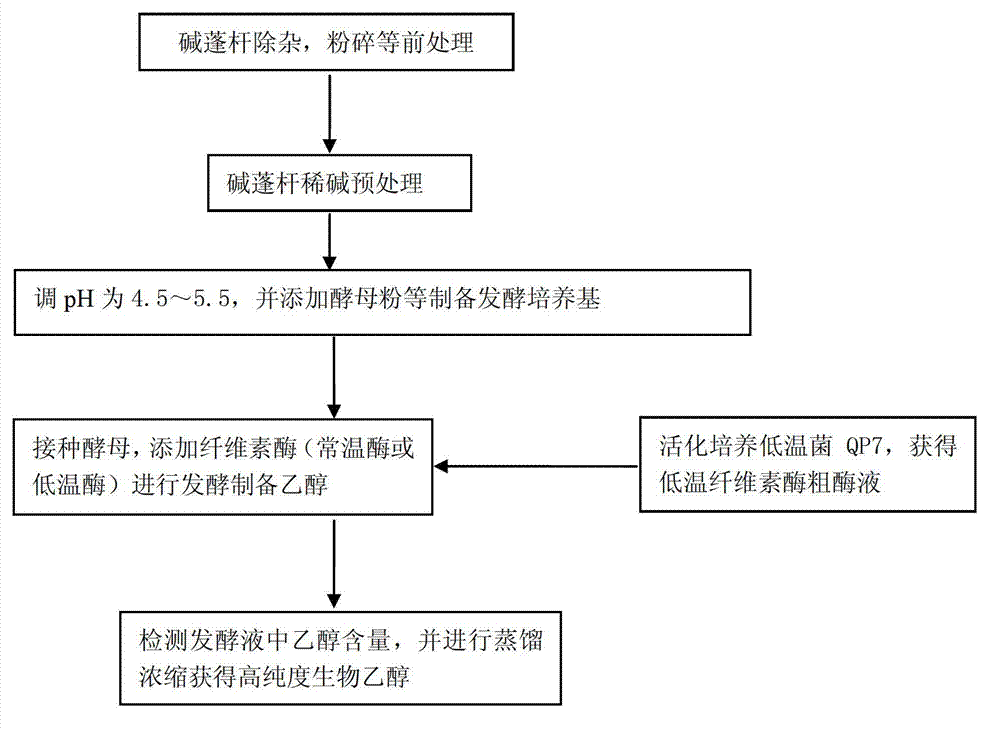

[0047] A method for preparing bioethanol with Suaeda salsa as raw material, its technical process is shown in figure 1 ,Specific steps are as follows:

[0048] (1) Pre-treatment of Suaeda stalks: ①Collect dry stalks and remove impurities; ②Dry the ①Salsa stalks after removal of impurities; 0.45—0.9mm;

[0049] (2) Pretreatment of Suaeda stalk: mix 800g of the treated stalk with 0.7% (w / w) sodium hydroxide solution at a solid-liquid ratio of 1:15 (g / ml), Treat at 110°C for 10 minutes;

[0050] (3) Preparation of Antarctic low-temperature cellulase: ① Inoculate and activate the Antarctic low-temperature bacterial strain QP7 screened from Antarctic soil samples preserved in the laboratory; In the enzyme production medium, the medium consists of (NH4) 2 SO 4 0.5% (g / ml), MgSO 4 0.02% (g / ml), bran 3% (g / ml), cultured on a low-temperature shaker at 150rpm, 15°C for 4 days; ③...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com