OLED (Organic Light Emitting Diode) device working under low voltage

A low-voltage, device technology, applied in the field of OLED devices, can solve the problems of device driving voltage increase, restricted mobility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

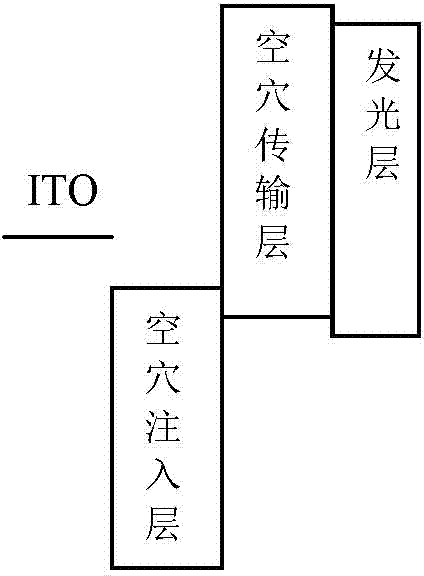

[0070] see image 3 The partial structural diagram of the inverted OLED device of the shown embodiment 1, embodiment 1 is a kind of green light-emitting device, adopts ITO as cathode, Alq 3 Doped cesium carbonate (cesium obtained by thermal decomposition) as electron injection layer, Alq 3 As the electron transport layer, AND doped C545T as the green light-emitting layer; NPB as the hole transport layer; HAT-cn as the hole injection layer. Alq 3 As an electron transport layer; LiF as an electron injection layer; Al as a metal anode layer. The device structure of this embodiment is as follows:

[0071] ITO / Alq 3 :10%Cs 2 CO 3 (20nm) / Alq 3 (5nm) / ADN: 2%C545T(30nm) / NPB(10nm) / HAT-cn(20nm) / Al(150nm) (1).

[0072] The specific preparation method for preparing the organic electroluminescent device with the above structural formula (1) is as follows:

[0073] The glass substrate was cleaned by detergent ultrasonic and deionized water ultrasonic, and dried under an infrared la...

Embodiment 2

[0090] Example 2 (see Figure 7 ):

[0091] Embodiment 2 is a blue light-emitting device of the present invention, using ITO as the cathode, Alq 3 Doped cesium carbonate (cesium obtained by thermal decomposition) as electron injection layer, Alq 3 As the electron transport layer, AND doped TBPe as the blue light-emitting layer; NPB as the hole transport layer; HAT-cn as the hole injection layer. Alq 3As an electron transport layer; LiF as an electron injection layer; Al as a metal anode layer. The device structure of this embodiment is as follows:

[0092] ITO / Alq 3 :10%Cs 2 CO 3 (20nm) / Alq 3 (5nm) / ADN:3%TBPe(30nm) / NPB(10nm) / HAT-cn(20nm) / Al(150nm) (2)

[0093] The preparation process of Example 2 is: using dual-source evaporation to prepare an AND and TBPe doped layer with a thickness of 30 nm and a TBPe doping ratio of 3%.

[0094] Evaporate 10nm thick NPB as a hole injection layer, and cover 20nm HAT-cn as a hole injection layer. Finally, 150 nm of Al was vapor-de...

Embodiment 3

[0104] Embodiment 3 (see Figure 11 ):

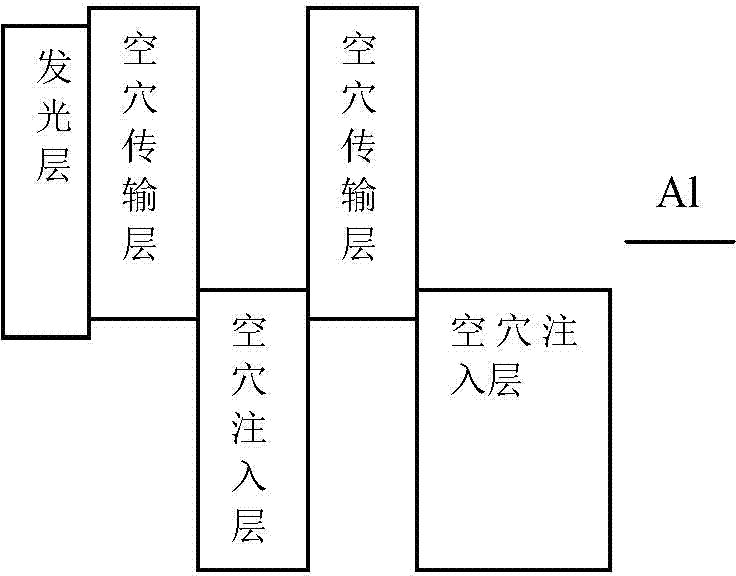

[0105] Embodiment 3 is a blue light-emitting device of the present invention, using ITO as the cathode, Alq 3 Doped cesium carbonate (cesium obtained by thermal decomposition) as electron injection layer, Alq 3 As the electron transport layer, AND doped TBPe as the blue light-emitting layer; NPB as the hole transport layer; HAT-cn as the hole injection layer. Alq 3 As an electron transport layer; LiF as an electron injection layer; Al as a metal anode layer. The device structure of this embodiment is as follows:

[0106] ITO / Alq 3 :10%Cs 2 CO 3 (20nm) / Alq 3 (5nm) / ADN: 3%TBPe(30nm) / NPB(20nm) / HAT-cn(20nm) / NPB(20nm) / HAT-cn(70nm) / Al(150n) (3).

[0107] The preparation process of Example 3 is: using dual-source evaporation to prepare an AND and TBPe doped layer with a thickness of 30 nm and a TBPe doping ratio of 3%.

[0108] Evaporate 20nm thick NPB as the hole injection layer, and at the same time cover 20nm HAT-cn as the hole in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com