Olive tea and preparation process thereof

A production process and olive tea technology, applied in the field of drinking tea processing, can solve the problems of difficulty in fully exerting the health-care effect of olive leaves, damage to the nutrition of olive leaves, olive tea is not high-quality pure natural olive tea, etc. Benefits, unique effects of crafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

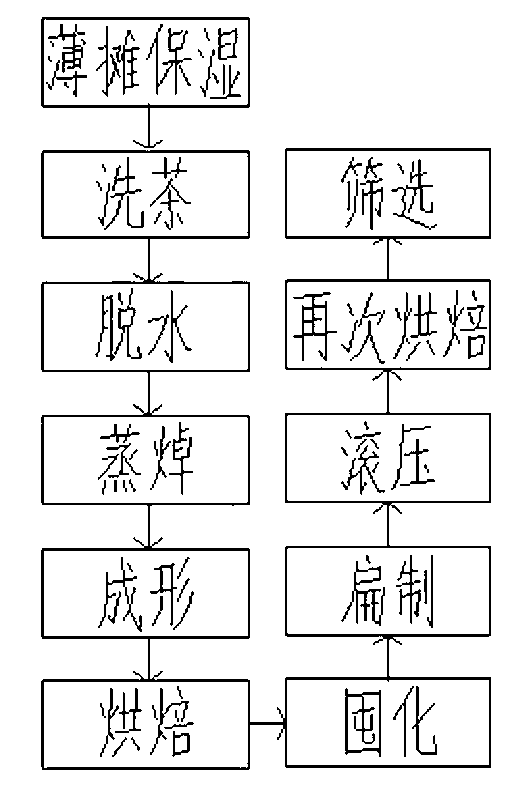

Image

Examples

Embodiment 1

[0029] The old leaves are selected from the pruned olive branches as raw materials, and the old leaves refer to the leaves with a growth period of 6 to 12 months, and the color is dark green; thinly spread and moisturizing, because a large number of old leaves are stacked, the internal leaves will be moldy and hot, and the appearance will be mildewed. The moisture of the leaves will be lost, the color will turn yellow and black, and a lot of nutrients will be lost. Therefore, it should be spread out and placed in a cool place, and the surface should be covered with a film to keep it fresh. The thickness of the old leaves is 8cm; The leaves are stained with some dust during the growth process. In order to ensure food hygiene, the old leaves need to be washed with clean water. There is a lot of water attached to the surface of the middle and old leaves. Use a drying machine to remove the water with a weight ratio of 80% on the surface of the old leaves, and retain 20% of the wate...

Embodiment 2

[0031] The young leaves are selected from the trimmed olive branches as raw materials, and the young leaves refer to the leaves with a growth period of 1 to 3 months, and the color is emerald green; The surface is covered with a film for moisturizing and fresh-keeping, and the thickness of the tender leaves is 5cm; for tea washing, the tender leaves are washed with water, and the number of cleanings is 4 times; dehydration, during the cleaning process, a lot of water is attached to the surface of the tender leaves. The dryer throws off the water with a weight ratio of 80% attached to the surface of the young leaves, and retains 20% of the water to adapt to the next step; steaming, in a high temperature environment with sufficient water vapor, steam the leaves with the heat of water , to achieve the effect of leaf preservation enzymatic, the steaming step uses a greening machine, the processing capacity of the greening machine is 10-25 kg / hour, and the greening machine has a sma...

Embodiment 3

[0033] The buds are selected from the pruned olive branches as raw materials, and the buds refer to the olive bud slices with a growth period of 15 to 20 days and a bright green color; thinly spread the moisturizing, spread the buds and place them in the shade, and place them in the shade. The surface is covered with a film for moisturizing and fresh-keeping, and the thickness of the sprouts is 3cm; for tea washing, the sprouts are washed with clean water, and the number of cleanings is 3 times; dehydration, during the cleaning process, a lot of water is attached to the surface of the sprouts. The drying machine throws off the water with a weight ratio of 80% attached to the surface of the tender leaves, and retains 20% of the water to adapt to the next step; steaming, in a high temperature environment with sufficient water vapor, the leaves are steamed with the heat of water vapor. Blanching, to achieve the effect of leaf greening enzymatic, the steaming step uses a greening mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com