Method for degrading octyl phenol by utilizing laccase

A technology of octylphenol and laccase, which is applied in the field of bioengineering and environmental pollutant treatment, can solve the problems of low degradation efficiency, long treatment time, secondary pollution, etc., achieve high removal efficiency, reduce reaction time, and reduce usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation of embodiment 1 laccase

[0052] 1.1 Preparation of recombinant laccases Lcc1 and Lcc2 from Coriolus versicolor

[0053] 1.1.1 Cultivation of Coriolus versicolor

[0054] Versicolor versicolor (Coriolus versicolor, the microorganism can be screened from nature, can also be purchased from commercial channels (for example, can be purchased from the China Industrial Microbiology Culture Collection Management Center)) medium is PDA: glucose 20g / L, Potato juice 20%wt, inoculated with fresh Versicolor versicolor mycelium, cultured at 180rpm at 28°C for 3-4 days and collected by filtration.

[0055] 1.1.2 Extraction of total RNA from Coriolus versicolor

[0056] The collected mycelia of Coriolus versicolor (Coriolus versicolor) was washed once with PBS buffer solution, ground the mycelium under liquid nitrogen to powder, collected into a 2mL centrifuge tube, added 1mL Trizol and shaken vigorously, 4 Centrifuge at 12000g at 12000g for 10min at ℃, transfer the...

Embodiment 2

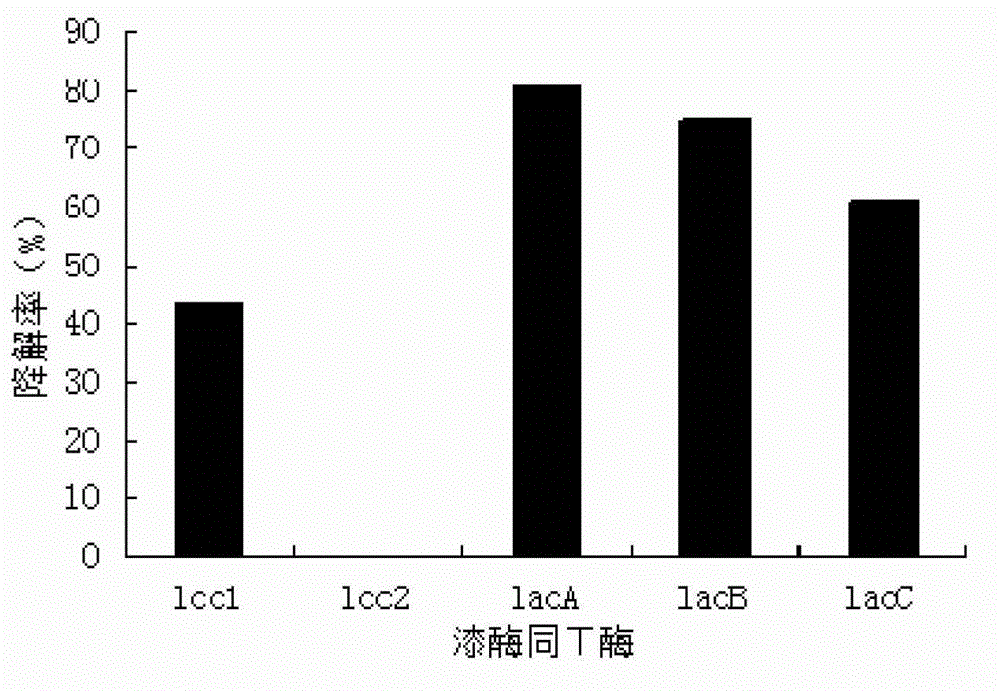

[0106] Example 2 Specificity of different recombinant laccase isoenzymes to octylphenol

[0107] Add five kinds of laccases to 2U / mL in the reaction system containing octylphenol 50mg / L; adjust the pH to 4.5 with citric acid buffer, control the temperature at 40°C; react in a water bath shaker at a speed of 100rpm After 24h, the residual amount of octylphenol was detected. Specific results such as figure 1 As shown, the degradation rates of octylphenol by the five laccases Lcc1, Lcc2, LacA, LacB, and LacC after 24 hours of reaction were 43.6%, 0%, 80.7%, 75.3%, and 61.1%, respectively. It indicated that laccase Lcc2 could not act on octylphenol, while laccase LacA had the best degradation effect on octylphenol. They are 1.9, 1.1, and 1.3 times of Lcc1, LacB, and LacC, respectively.

[0108] The detection method of octylphenol is as follows: first, add an equal volume of petroleum ether to the 10mL reaction system for liquid-liquid extraction, and extract each sample three t...

Embodiment 3

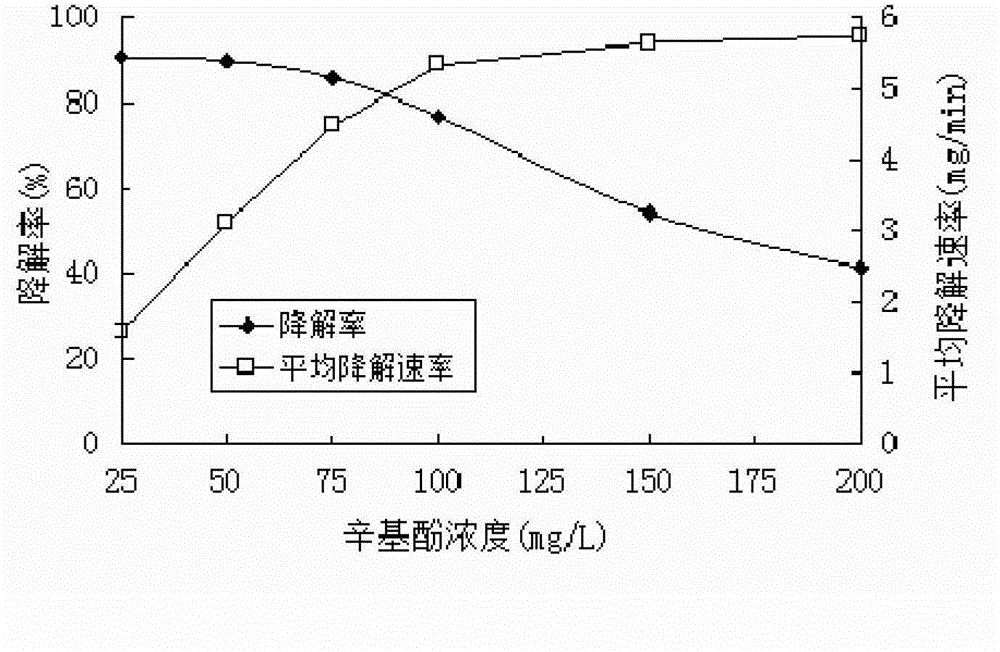

[0111] Example 3 Effect of laccase LacA on degrading octylphenol pollutants under different octylphenol concentrations

[0112] The concentration of octylphenol in the reaction system is 25mg / L, 50mg / L, 75mg / L, 100mg / L, 150mg / L, 200mg / L, add laccase LacA to a concentration of 2U / mL, and use citrate buffer Adjust the pH to 4.5, control the temperature at 40° C., and detect the residual amount of octylphenol after reacting in a water-bath shaker at a speed of 100 rpm for 24 hours. Test results such as figure 2 Shown: degradation rate decreases gradually along with the increase of octylphenol concentration; When the concentration of octylphenol was lower than 100mg / L, the average degradation rate of octylphenol showed a linear growth trend, and when the concentration continued to increase, octylphenol The upward trend of the average degradation rate of phenol is slow. Therefore, the substrate concentration should be controlled within a certain range (octylphenol concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com