Fischer-Tropsch synthesis cobalt-based catalyst and preparation method thereof

A technology of cobalt-based catalysts and Fischer-Tropsch synthesis, which is applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., can solve problems such as difficult product concentration, insufficient CO conversion rate, and increased costs, and achieve The effect of stabilizing catalyst activity, improving product distribution and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

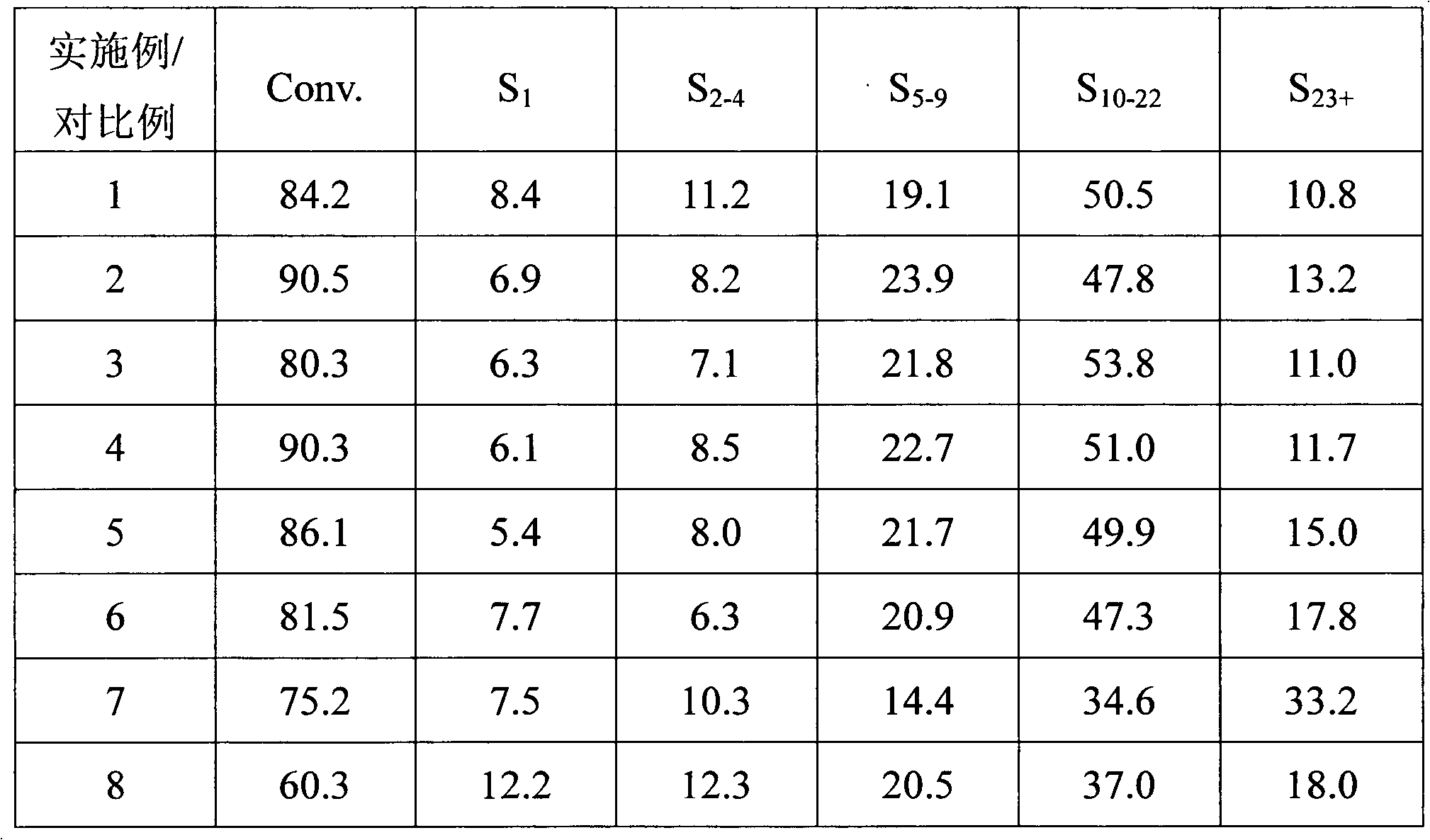

Examples

Embodiment 1

[0046] Weigh 40.0g aluminum nitrate (Al(NO 3 ) 3 9H 2 O 375.13), add 400.0g absolute ethanol, stir to dissolve, then add 30.0g silica gel (calculated as silicon dioxide) and 0.5g polyethylene glycol, continue to stir for 1h; Add 20wt% ammonium carbonate dropwise under constant stirring Solution, adjust the pH value to 9.0; adjust the temperature to 90°C, stir and reflux for 3h, move the obtained solid-liquid mixture to an oven and dry at 100°C for 10h, then move to a muffle furnace and bake at 450°C for 4h; Get 2.0g of 3-aminopropyltriethoxysilane, add 100.0g of absolute ethanol, then add the above-mentioned roasted sample, adjust the temperature to 100°C, reflux and stir for 3h; take by weighing 5.0g of boric acid (H 3 BO 3 61.81), add to the above mixed solution, continue to reflux and stir for 6h; filter the obtained solid-liquid mixture, move the obtained filter cake to an oven and dry at 100°C for 15h, then move to a muffle furnace and roast at 450°C for 5h, The obtai...

Embodiment 2

[0050] Weigh 2.18g niobium chloride (NbCl 5 270.17), add a certain amount of deionized water to make a solution with a concentration of 1.0wt%, and stir for 1h; weigh 15.0g of SiO obtained in Example 1 according to the proportioning ratio 2 -Al 2 o 3 -B 2 o 3 Add it into the above solution, stir for 10 hours, and then stand still for 4 hours; evaporate the obtained solid-liquid mixture to dryness at 80°C, and then dry it in vacuum at 70°C for 15 hours; weigh 21.17g of cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O 291.05), add a certain amount of deionized water to make a 5.0wt% solution, stir for 1h; take by weighing 3.79g manganese nitrate (Mn(NO 3 ) 2 4H 2 O 250.94), added to the above solution, and stirred for 0.5h; the sample obtained after vacuum drying was added to the above solution, stirred for 10h, and left standing for 10h; the obtained solid-liquid mixture was evaporated to dryness at 100°C, and then Vacuum drying at ℃ for 24 hours; fully grind the dried solid for 1...

Embodiment 3

[0053] Weigh 40.0g aluminum chloride (AlCl 3 ·6H 2 (241.34), add 400.0g absolute ethanol, stir and dissolve, then add 30.0g fumed silicon dioxide and 1.5g polyvinyl alcohol, continue to stir for 1h; add 10wt% ammonium carbonate solution drop by drop under constant stirring, adjust the pH value 9.0; adjust the temperature to 90°C, stir and reflux for 3h, move the obtained solid-liquid mixture to an oven and dry at 100°C for 10h, then move to a muffle furnace and roast at 450°C for 4h; weigh 4.0g of 3- Aminopropyltriethoxysilane, add 100.0g of absolute ethanol, then add the above-mentioned roasted sample, adjust the temperature to 100°C, reflux and stir for 3h; weigh 8.0g boric acid (H 3 BO 3 61.81), add to the above mixed solution, continue to reflux and stir for 6h; filter the obtained solid-liquid mixture, move the obtained filter cake to an oven and dry at 100°C for 15h, then move to a muffle furnace and roast at 450°C for 5h, The obtained sample is ground into SiO 2 -A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com