Preparation method and application of zinc oxide visible-light-induced photocatalyst sensitized by squarylium cyanine

A dye sensitization, zinc oxide technology, applied in the field of photocatalysis, can solve problems such as no substantial breakthrough, and achieve the effects of easy control, simple process and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

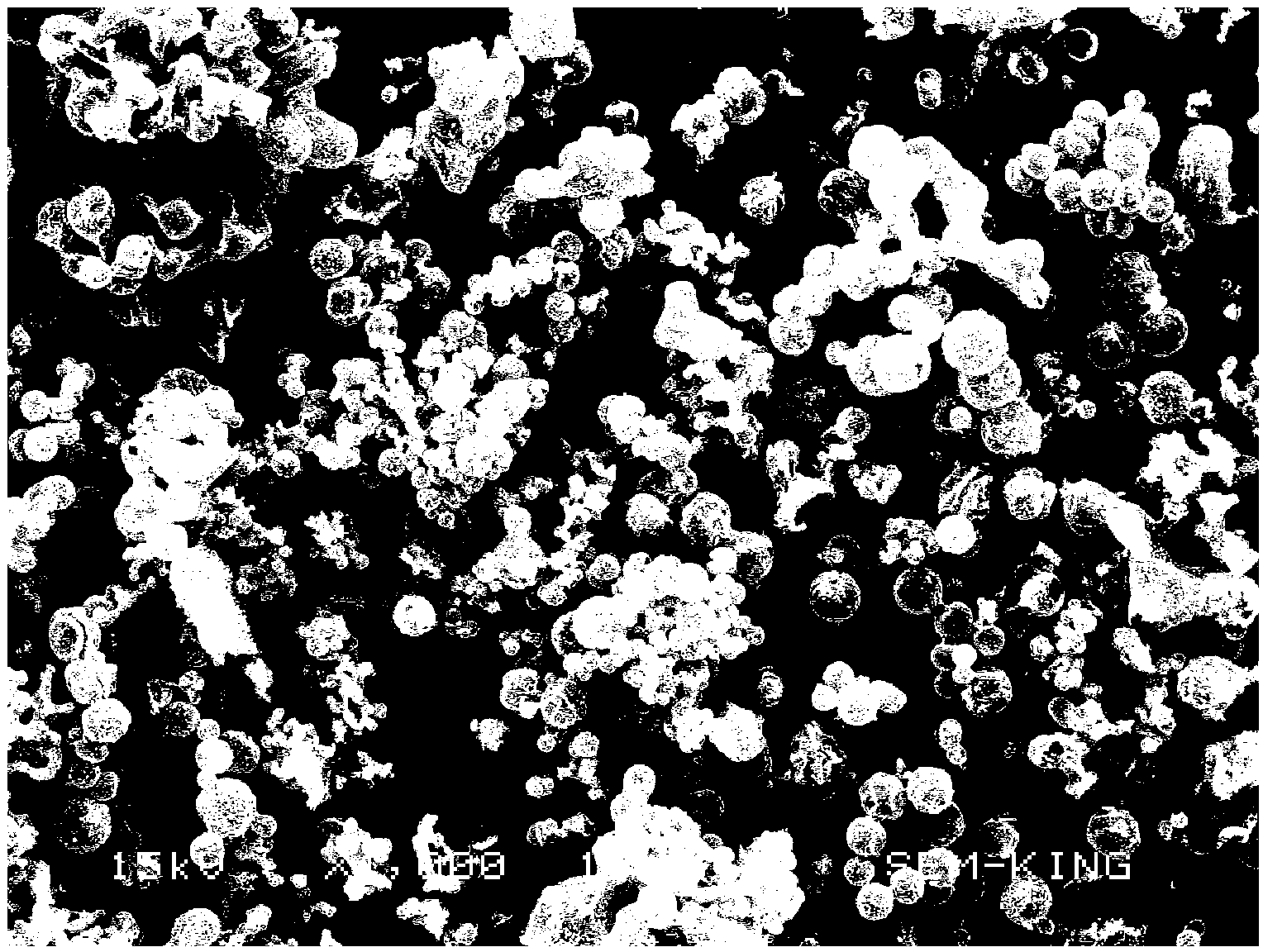

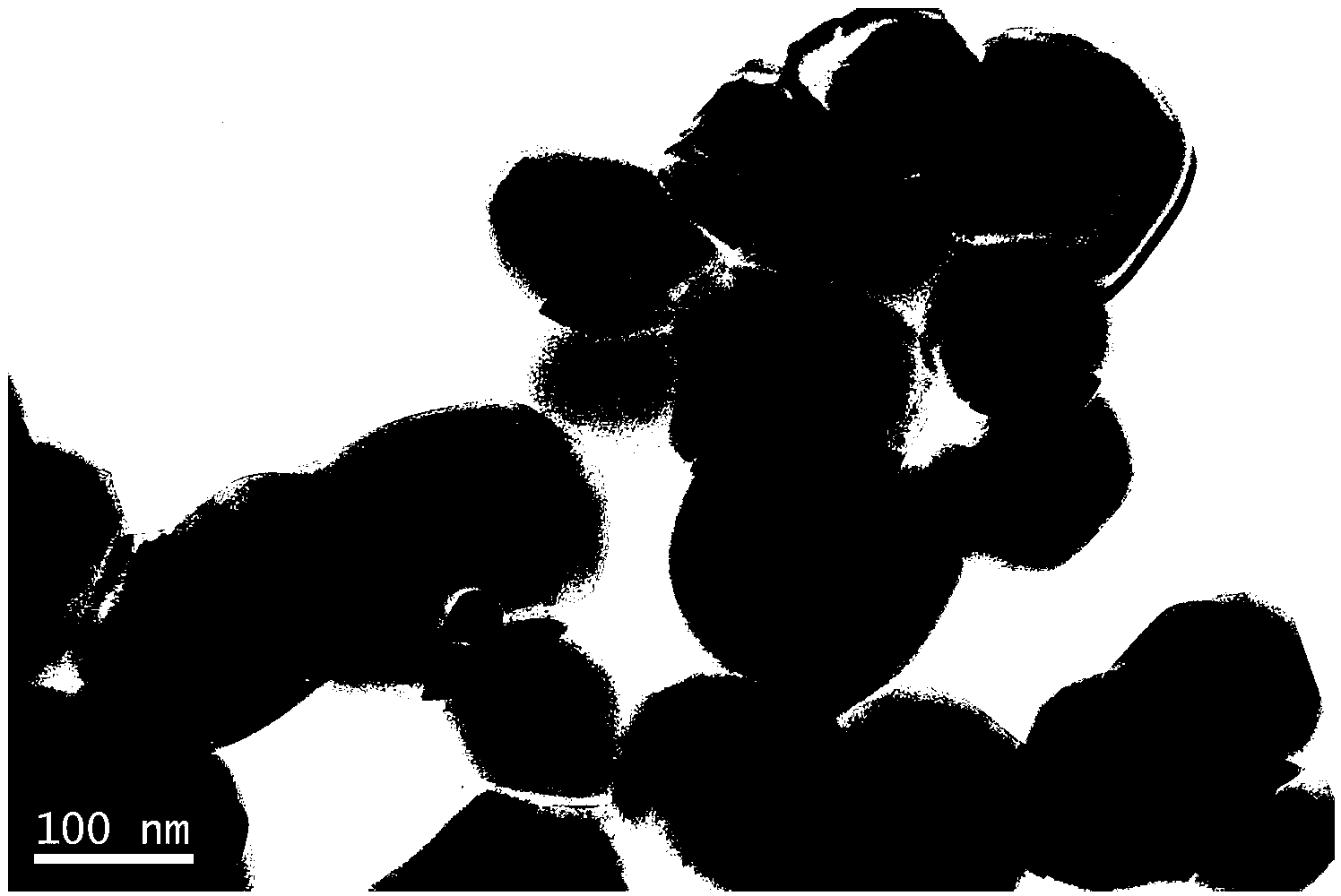

[0027] Weigh Zn(Ac) with a mass ratio of 1:2 2 .2H 2 O and glucose were dissolved in deionized water and ultrasonically formed to form a clear solution. After the solution was transferred to the liner of a polytetrafluoroethylene autoclave, the hydrothermal reaction was carried out at 180°C for 12 hours. After cooling to room temperature, the obtained black powder was used separately. Ionized water and absolute ethanol were subjected to several centrifugal washings, and then dried at 60°C to obtain a composite precursor of zinc oxide and carbon, which was then calcined in a muffle furnace at 600°C for 3 hours to obtain zinc oxide microparticles. ball. The scanning electron microscope and transmission electron microscope pictures of the prepared zinc oxide microspheres are as follows: figure 1 with figure 2 shown. It can be seen from the figure that zinc oxide has good dispersibility.

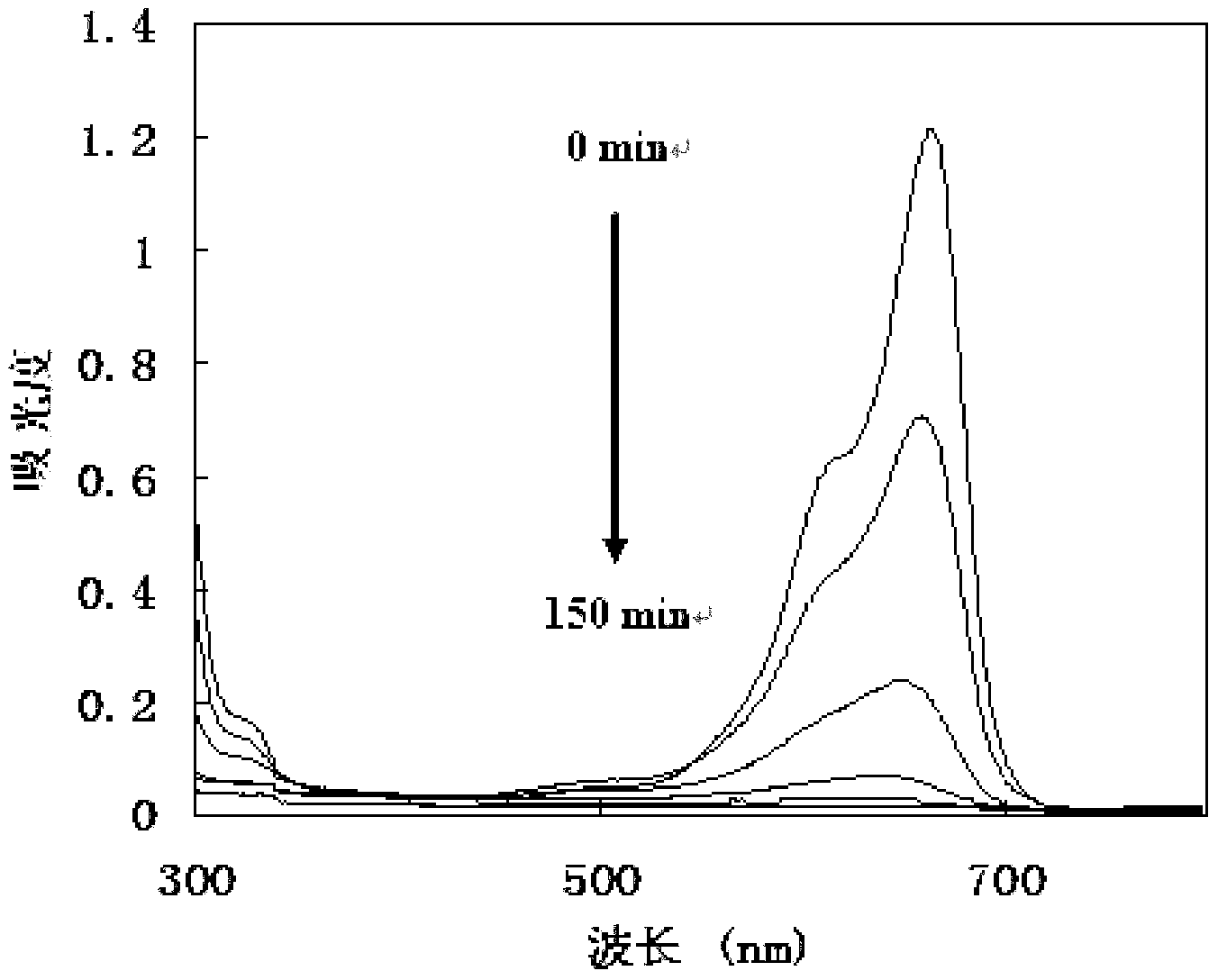

[0028] The zinc oxide microspheres obtained above were mixed with 2,3,3-trimethyl-3H i...

Embodiment 2

[0030] Weigh Zn(Ac) with a mass ratio of 1:3 2 .2H 2 O and glucose were dissolved in deionized water and ultrasonically formed to form a clear solution. After the solution was transferred to a polytetrafluoroethylene autoclave liner, the hydrothermal reaction was carried out at 140°C for 24 hours. After cooling to room temperature, the obtained black powder was used in Ionized water and absolute ethanol were subjected to several centrifugal washings, and then dried at 60°C to obtain a composite precursor of zinc oxide and carbon, which was then calcined in a muffle furnace at 400°C for 3 hours to obtain zinc oxide ball.

[0031] The zinc oxide microspheres obtained above were mixed with 2,3,3-trimethyl-3-ethylindole substituted squarylium dye [R 1 for C 2 h 5 , R 2 for C(CH 3 )] and 60ml of methanol were added to a single-necked flask, wherein the mass ratio of nano-zinc oxide to 2,3,3-trimethyl-3-ethylindole substituted squarylium dye was 100:5, at a temperature of 30°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com