Preparation method for reduced-oxidized graphene/cuprous sulfide hybrid structure

A cuprous sulfide, hybrid structure technology, applied in copper sulfide, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of semiconductor nanomaterial growth regulation and lack of uniformity, and achieves easy commercial production and size controllable. Strong, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

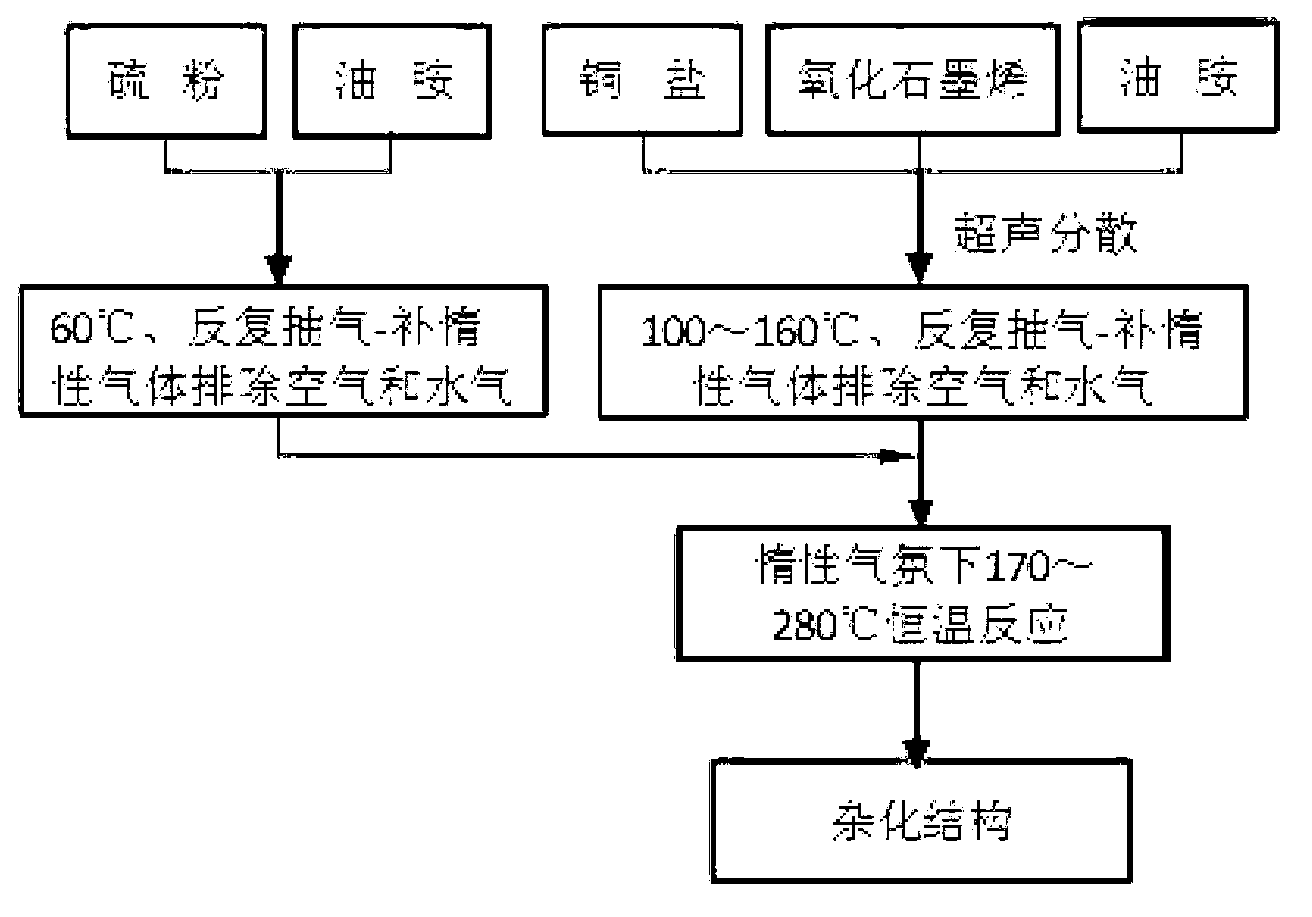

[0022] A method for preparing a reduced graphene oxide / cuprous sulfide hybrid structure. The method utilizes graphene oxide in-situ reduction and cuprous sulfide in-situ growth to prepare a graphene / cuprous sulfide hybrid structure. The flow chart is as follows figure 1 shown, including the following steps:

[0023] 1) Graphene oxide pretreatment

[0024] The graphene oxide prepared by the improved Hummers method was centrifugally precipitated, then ethanol was added for ultrasonic dispersion and secondary centrifugal precipitation was performed, and the above-mentioned cycle treatment was performed to remove the moisture contained in the graphene oxide.

[0025] (2) Preparation of reduced graphene oxide / cuprous sulfide hybrid structure

[0026] Mix the pretreated graphene oxide with oleylamine and copper salt into a three-necked flask and disperse evenly by ultrasonic; the copper salt used can be copper acetylacetonate, copper sulfate, copper chloride or copper nitrate, and ...

Embodiment 1

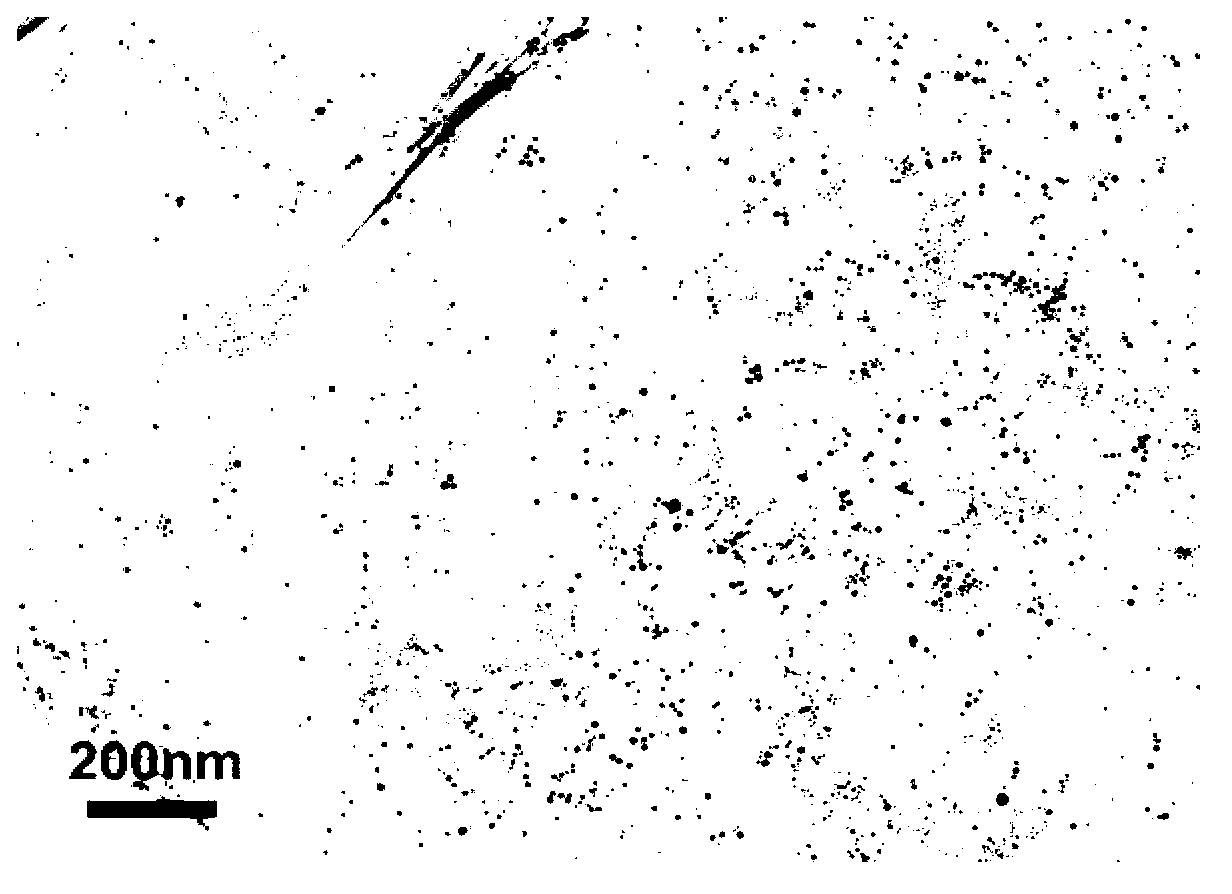

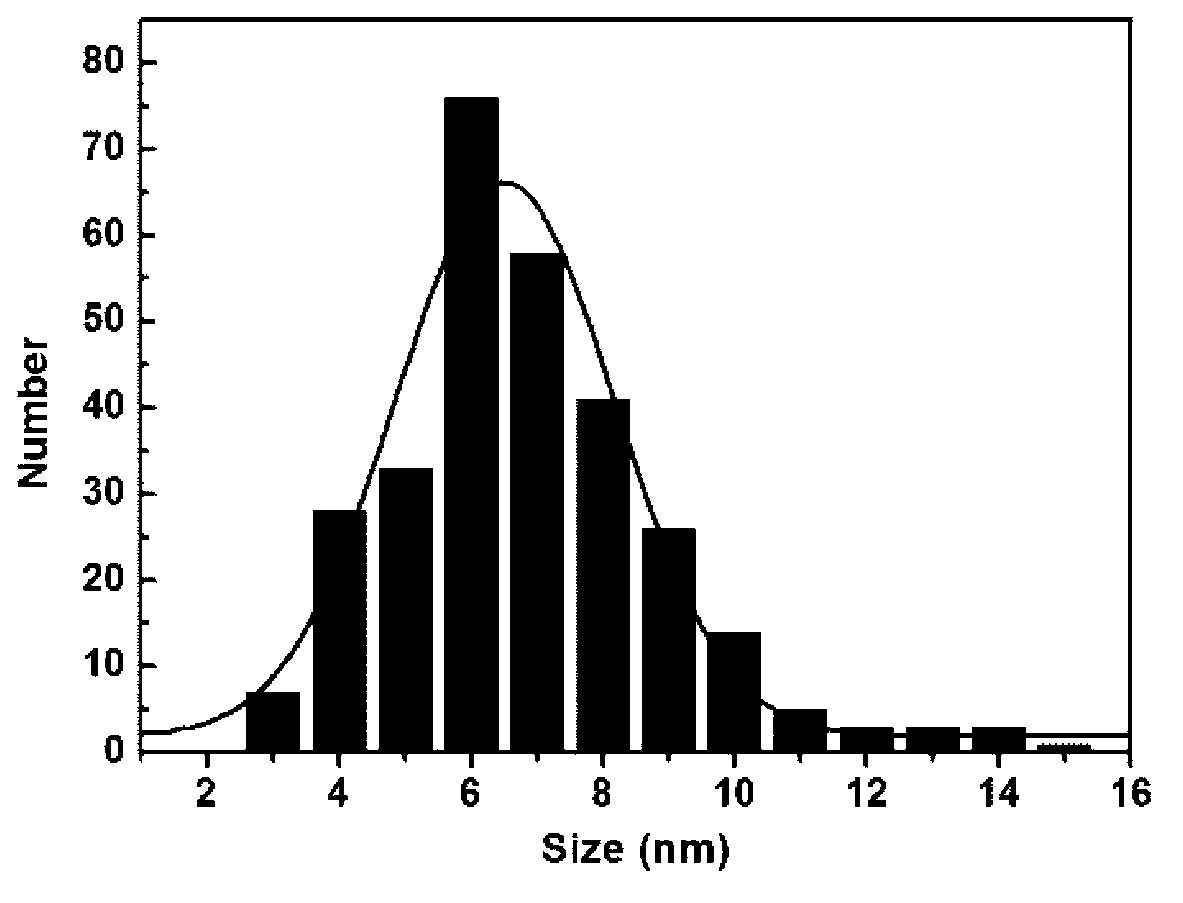

[0029] The graphene oxide prepared by the improved Hummers method was centrifuged and precipitated at 12000rpm, then ethanol was added for ultrasonic dispersion for 60min, and then centrifuged at 12000rpm, and the above-mentioned cycle treatment was performed to remove the moisture contained in the graphene oxide. Mix the pretreated 12mg graphene oxide, 68mg anhydrous cupric chloride and 10ml oleylamine into a three-neck flask and ultrasonically disperse for 30min; heat the mixed solution to 100°C and keep it warm for 60min, during which time pumping-filling is repeated. Nitrogen to exclude air and moisture; at the same time, dissolve 32mg of sulfur powder in 10ml of 60°C oleylamine under nitrogen protection, and repeatedly pump air-fill with nitrogen to remove moisture to form a clear solution; when the temperature of the mixed solution rises to 170°C The amine solution was injected and reacted at a constant temperature for 30 minutes; when the reaction was completed and the t...

Embodiment 2

[0031] The graphene oxide prepared by the improved Hummers method was centrifuged and precipitated at 12000rpm, then ethanol was added for ultrasonic dispersion for 60min, and then centrifuged at 12000rpm, and the above-mentioned cycle treatment was performed to remove the moisture contained in the graphene oxide. Mix the pretreated 12mg graphene oxide, 180mg copper acetylacetonate and 10ml oleylamine into a three-necked flask and ultrasonically disperse it for 30 minutes; heat the mixed solution to 140°C and keep it warm for 30 minutes, during which time it is repeatedly pumped-nitrogen to Exclude air and moisture; at the same time, dissolve 48mg of sulfur powder in 10ml of 60°C oleylamine under nitrogen protection, and repeatedly pump air-fill with nitrogen to remove moisture to form a clear solution; when the temperature of the mixed solution rises to 200°C The solution was injected and reacted at a constant temperature for 60 minutes; when the reaction was completed and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com