Method for improving flexible AZO (aluminum doped zinc oxide) film photoelectric property by excimer laser

A technology of excimer laser and excimer laser, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem of ineffective use of deposition technology, physical and chemical damage of flexible materials, substrate Reduced transmittance and other issues, to achieve the effect of eliminating lattice defects, improving photoelectric performance, and improving photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

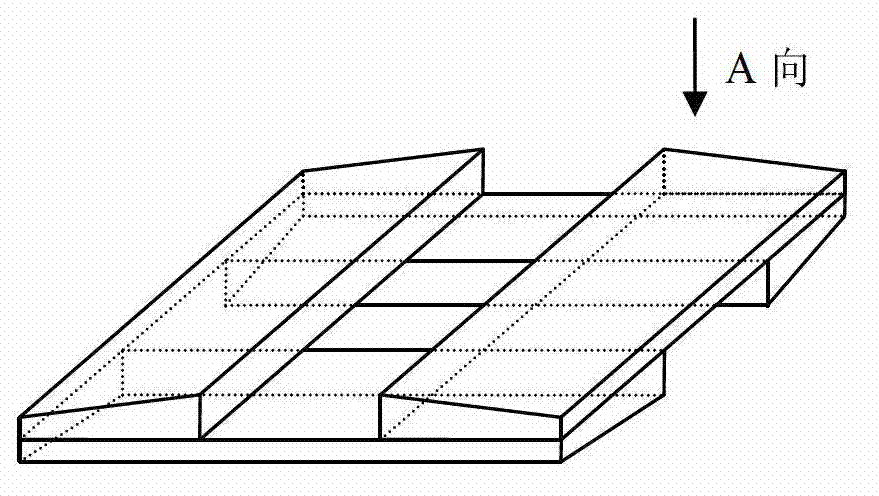

[0024] Select the flexible PET substrate 8 and clean it; grow a layer of aluminum-doped zinc oxide film 7 on the PET substrate 8 by using film deposition technology; place the PET substrate 8 with the aluminum-doped zinc oxide film 7 on the base 9 , the film was irradiated by excimer laser annealing.

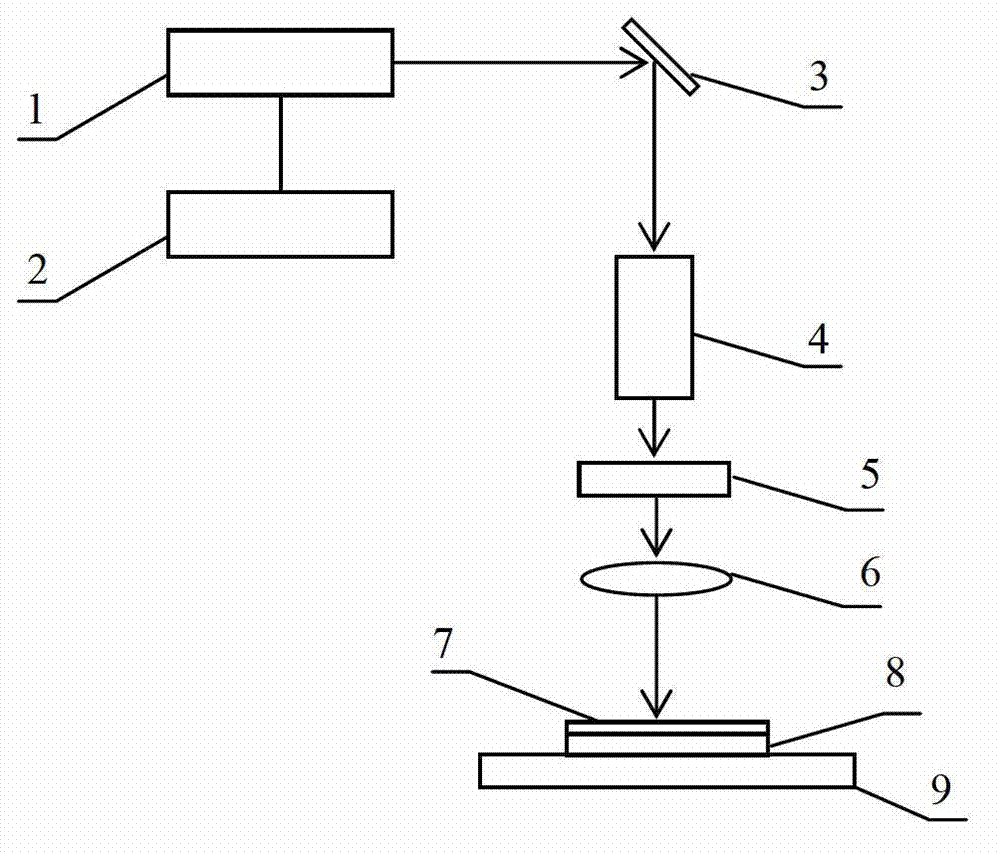

[0025] Such as figure 1 As shown, the excimer laser annealing device includes: an excimer laser 1 for providing laser light; a power controller 2 for adjusting voltage, pulse frequency and laser energy; a mirror 3; A device 4; a square diaphragm 5 that turns the shaped laser into a specified size; a convex lens 6 for adjusting the spot size; a flexible PET substrate 8 with an aluminum-doped zinc oxide film 7 grown on it; a base 9 for carrying the substrate.

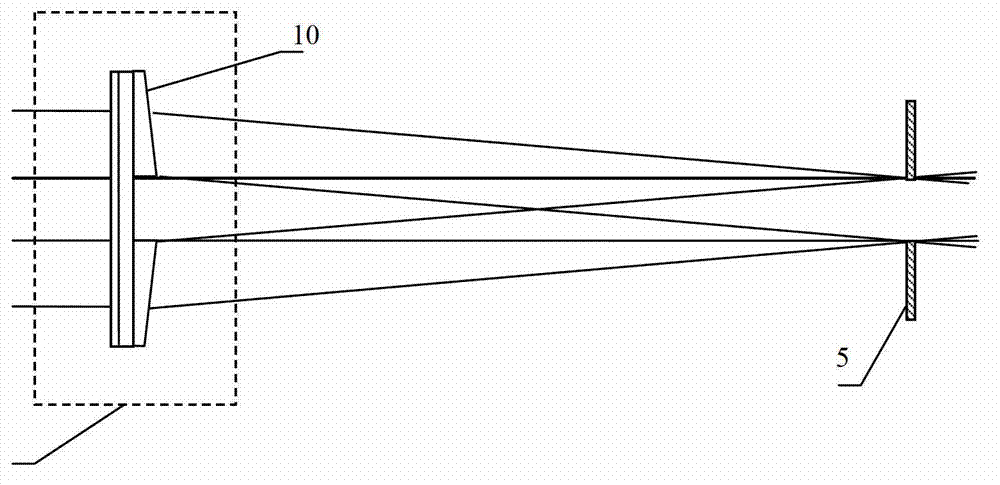

[0026] In the embodiment device of the present invention, a KrF excimer laser 1 is used, and the laser beam emitted by the KrF excimer laser 1 is a rectangular spot with a spot size of 8mm×20mm. Because the laser spot wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com