Gaseous-phase in-situ polymerization method for preparing ultra-high molecular weight polyethylene graphene composite material

An ultra-high molecular weight, gas-phase in-situ technology, which is applied in the field of gas-phase in-situ polymerization to prepare ultra-high molecular weight polyethylene graphene composite materials, can solve the problems of material brittle fracture, material impact resistance reduction, failure, etc., and achieve brittleness Fracture, excellent performance, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

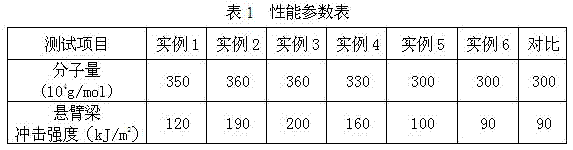

Examples

Embodiment 1

[0042] Take 0.12 g of graphene and treat it at 110°C for 1.0 hour, make a suspension of the treated graphene and 100 ml of heptane, add 0.5 ml , heated to reflux temperature, and reacted at this temperature for 0.5 hours, and filtered. Gained solid was washed 3 times at 30~60 DEG C with 30 milliliters of hexanes, then in 60 DEG C The solid catalyst was obtained by drying in a stream for 1 hour. Its graphene content is 63wt%. Use a 500 ml three-necked flask equipped with a stirrer and a constant temperature system Replace by pumping three times, and replace once with ethylene. Add 200 ml of hexane, 0.15 ml of 1.5M triisobutylaluminum and 0.004 g of solid catalyst (molar ratio 30:1) in sequence, start stirring, and after 5 min, remove the solvent and feed ethylene gas, at 40°C and normal pressure The reaction was stopped after 2 hours, and the obtained polymer was dried in an oven to obtain 50 grams of off-white powdery composite material.

[0043] The graphene content i...

Embodiment 2

[0045] Take 0.25 grams of graphene and treat it at 150°C for 6 hours, make a suspension of the treated graphene and 100 milliliters of heptane, add 0.5 milliliters , heated to reflux temperature, and reacted at this temperature for 2 hours, and filtered. Gained solid was washed 3 times at 30~60 DEG C with 30 milliliters of hexanes, then in 60 DEG C The solid catalyst was obtained by drying in stream for 0.5-1 hour. Its graphene content is 81wt%. Use a 500 ml three-necked flask equipped with a stirrer and a constant temperature system Replace by pumping three times, and replace once with ethylene. Add 200 ml of hexane, 0.8 ml of 1.5M triisobutylaluminum and 0.012 g of solid catalyst (molar ratio 100:1) in sequence, start stirring, and after 10 min, remove the solvent and feed ethylene gas, at 50 ° C, 0.01 MPa The reaction was stopped after 5 hours, and the obtained polymer was dried in an oven to obtain 50 grams of off-white powdery composite material.

[0046] The graph...

Embodiment 3

[0048] Take 0.5 grams of graphene and treat it at 200°C for 6 hours, make a suspension of the treated graphene and 100 milliliters of heptane, add 0.5 milliliters , heated to reflux temperature, and reacted at this temperature for 2 hours, and filtered. Gained solid was washed 3 times at 30~60 DEG C with 30 milliliters of hexanes, then in 60 DEG C The solid catalyst was obtained by drying in stream for 0.5-1 hour. Its graphene content is 90wt%. Use a 500 ml three-necked flask equipped with a stirrer and a constant temperature system Replace by pumping three times, and replace once with ethylene. Add 200 ml of hexane, 0.42 ml of 1.5M triisobutylaluminum and 0.027 g of solid catalyst (molar ratio 45:1) in sequence. After 15 minutes, remove the solvent, start stirring, and feed ethylene gas. The reaction was stopped after 10 hours, and the obtained polymer was dried in an oven to obtain 50 grams of off-white powdery composite material.

[0049] The graphene content in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com