High-efficiency heat-dissipating paint composition using a carbon material

一种散热涂料、组合物的技术,应用在防火涂料、热交换的材料、涂层等方向,能够解决难以实现电传导性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

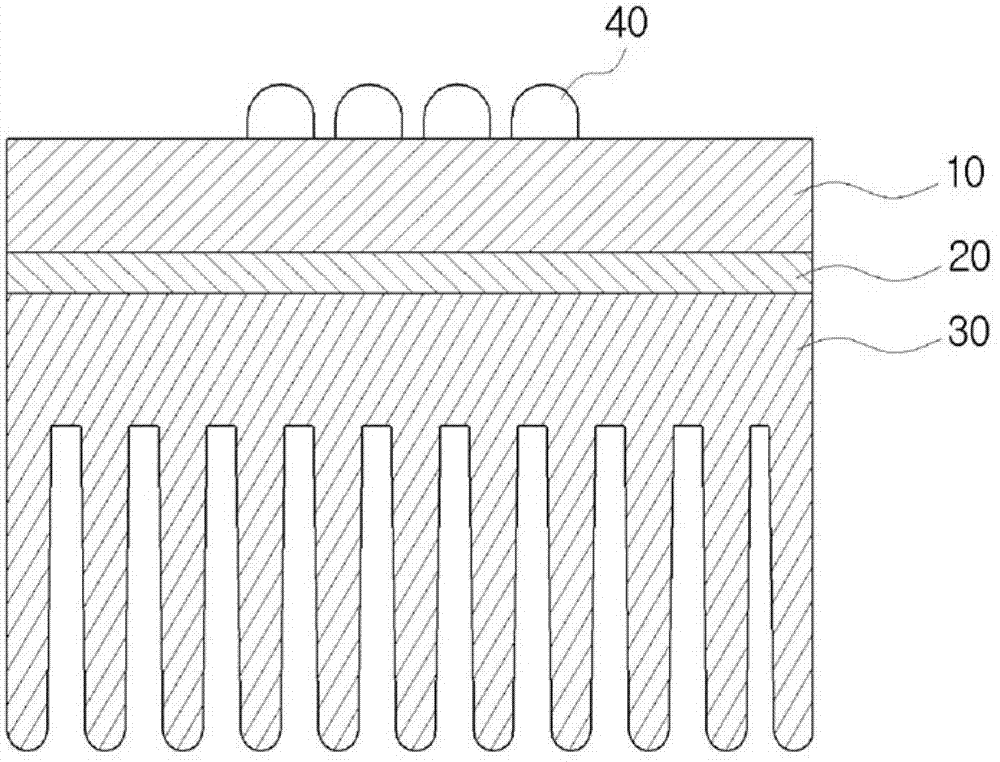

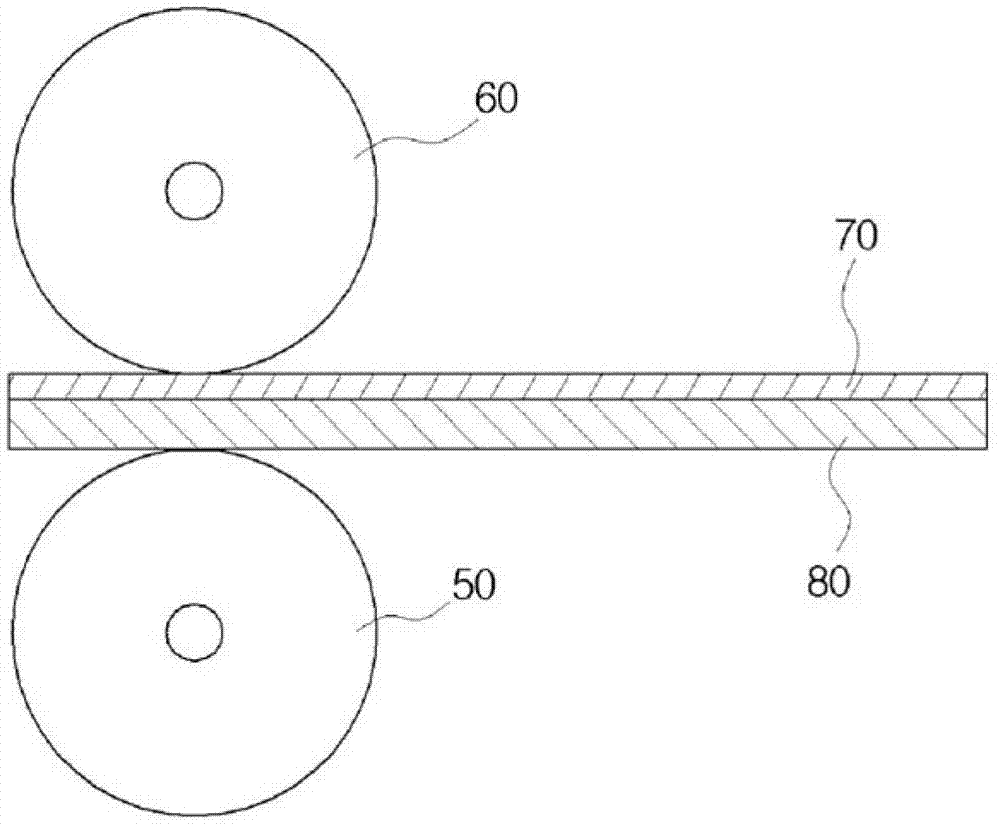

Image

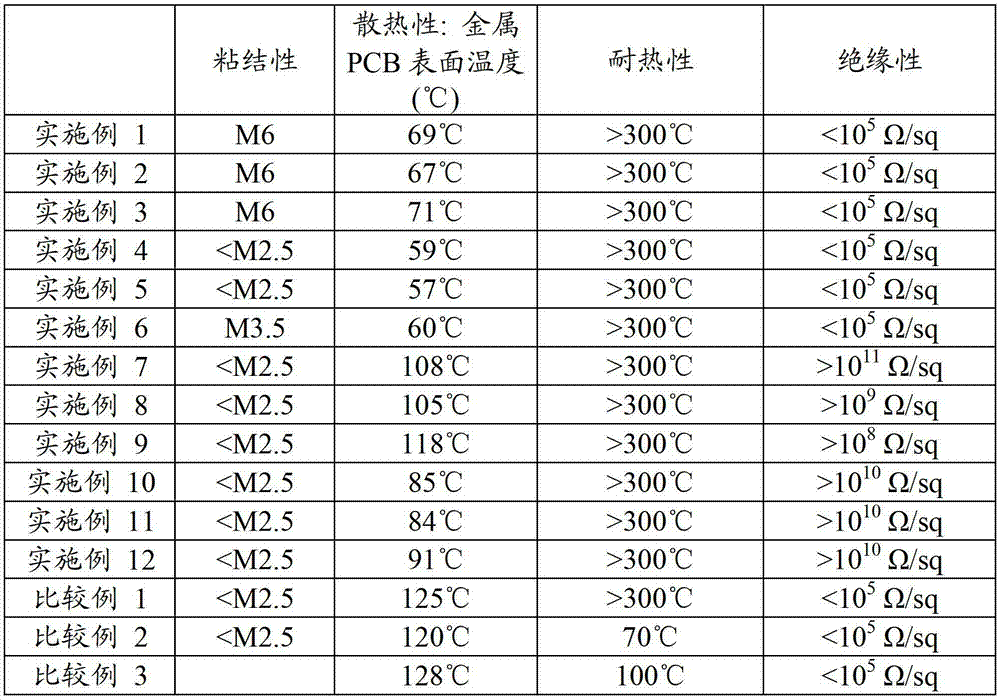

Examples

preparation example 1

[0093] Preparation of a dispersion comprising a surface-modified carbon material

[0094] A CNT aqueous solution was prepared in a pretreatment tank by mixing 15 g of carbon nanotubes (CNT) and 985 g of distilled water with a circulation pump. Before the CNT solution is injected into the preheating tank at a flow rate of 30g / min by a high-pressure injection pump, the gaseous oxygen compressed to 252atm is mixed with the CNT solution at a flow rate of 0.8g / min at the front end of the heat exchanger, and the mixed solution is injected into the preheating tank. It is preheated to 200°C in a preheating tank by a heat exchanger. The preheated mixed solution is injected into a surface modification reactor in a critical pressure water state at 210° C. and 250 atm, and then the mixed solution is subjected to surface modification. The surface-modified product was sent back to the heat exchanger, first cooled to 100°C, and then cooled to about 25°C by a cooling device, thereby obtain...

preparation example 2

[0097] Preparation of Heat Resistance Additives

[0098] Heat-resistant additive.

[0099] At this time, the alkali-soluble resin was used by mixing 52.1% by weight of water, 1.9% by weight of ammonia water, and 46% by weight of solids. As the solid, a water-soluble resin based on styrene / acrylic acid (with a weight average molecular weight of 100,000, including 35% by weight of styrene, 32.5% by weight of α-methyl Styrene, 32.5% by weight acrylic acid), 4.2% by weight styrene, 73.3% by weight 2-ethylhexyl acrylate, 1.2% by weight glycidyl methacrylate and A resin obtained by reacting 0.6% ammonium peroxide as an initiator.

preparation example 3

[0101] Preparation of emulsions with enhanced cohesive properties

[0102] A bond with reinforcement was prepared by mixing 54.9% by weight of water, 0.2% by weight of 27% ammonia, 44.9% by weight of an acrylic-based resin (weight average molecular weight: 15,000) as a solid sexual emulsion.

[0103] At this time, the acrylic acid-based resin used as the solid was used by making 49.0% by weight of butyl acrylate, 49.4% by weight of methyl methacrylate, 0.6% by weight of itaconic acid, A resin obtained by reacting 0.6% of a silane coupling agent (aminopropyltrimethoxysilane) and 0.4% by weight of ammonium peroxide as an initiator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com