Preparation method of amino-containing copolymer film separating acidic gas

A copolymer membrane and acid gas technology, which is applied in the field of preparation of amino-containing polymer membranes, can solve the problems of decreased permeation and separation performance, and achieve good acid gas permeation and separation performance, simple method, and good economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

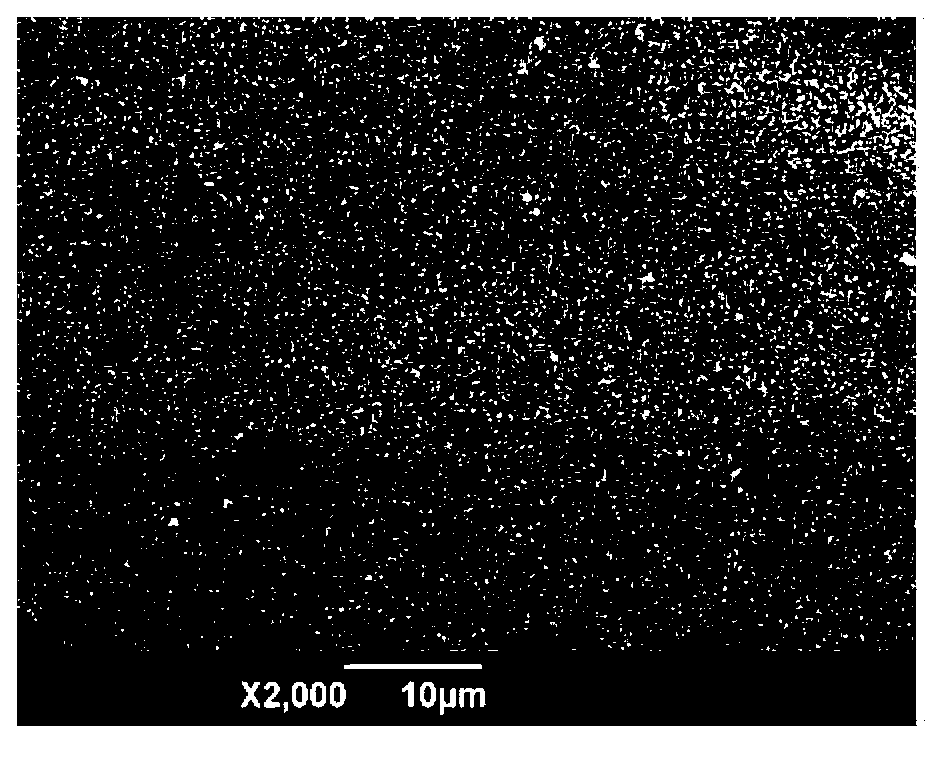

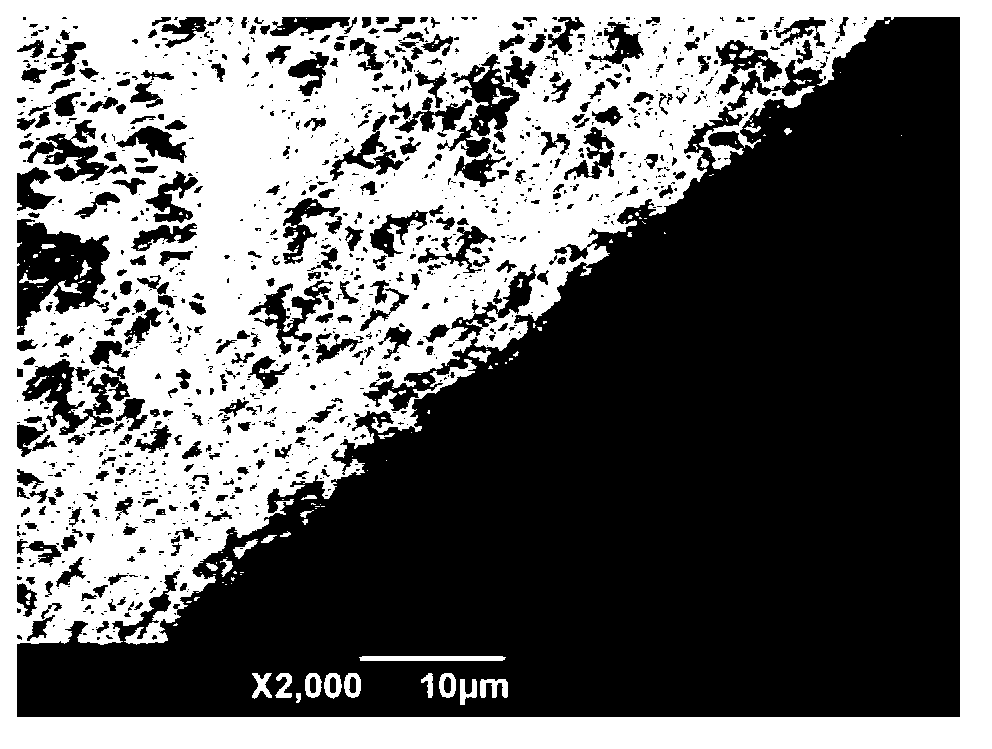

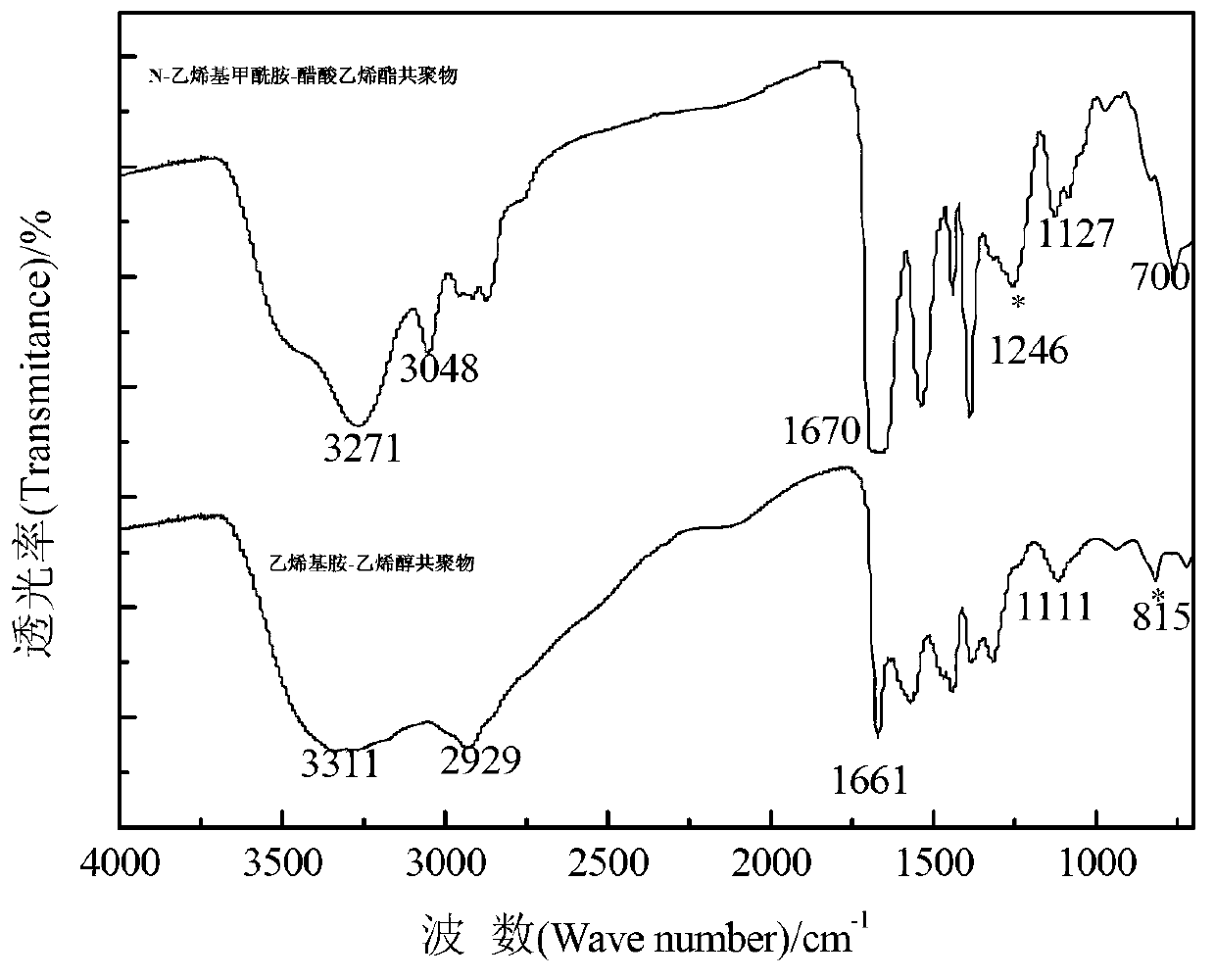

[0021] Add 0.05 g of azobisisobutyromidine hydrochloride and 1 g of N-vinylformamide successively into a three-necked flask equipped with a stirrer and a condenser. After the azobisisobutyronitrile is dissolved, add 9 g of 10 g of methanol solution of vinyl acetate was purged with nitrogen for 30 minutes, then polymerized in a water bath at 70° C. for 4 hours to obtain a copolymer of N-vinylformamide and vinyl acetate. Then add methanol solution containing 0.3mol / L NaOH to the polymer, and alcoholyze at 70°C for 20 minutes; Hydrolyze for 90 minutes at ℃ to obtain vinylamine-vinyl alcohol copolymer hydrochloride; after ethanol precipitation, anion exchange and other impurity removal and purification processes, it is prepared into a polymer solution with a concentration of 1.8%, and coated on polysulfone ultrafiltration membrane (molecular weight cut-off 6000) surface layer, the obtained film was dried at 30° C. for 10 hours. Using CO 2 / N 2 Mixed gas (20vol%CO 2 ,80vol%N 2...

Embodiment 2

[0023] Add 0.075 g of azobisisobutyramide hydrochloride and 7.5 g of N-vinylformamide in sequence in a three-necked flask equipped with a stirrer and a condenser, and after the azobisisobutyramide hydrochloride is dissolved, add the 7.5 g of vinyl acetate in 6 g of methanol solution was purged with nitrogen for 30 minutes, then polymerized in a water bath at 60° C. for 3 hours to obtain a copolymer of N-vinylformamide and vinyl acetate. Then add a methanol solution containing 0.1mol / L NaOH to the copolymer, and alcoholyze it at 45°C for 30 minutes; dissolve the obtained solid in water, prepare a 5% aqueous solution by adding 1mol / L HCl, and hydrolyze it at 50°C After 90 minutes, vinylamine-vinyl alcohol copolymer hydrochloride was obtained; after ethanol precipitation, anion exchange and other impurity removal and purification processes, water was added to prepare a polymer solution with a mass concentration of 2%. The solution is coated on the surface layer of a polysulfone u...

Embodiment 3

[0025]Add 0.05 g of azobisisobutylamidine hydrochloride and 7 g of N-vinylformamide in sequence in a three-necked flask equipped with a stirrer and a condenser. After the azobisisobutylamidine hydrochloride is dissolved, add the A solution of 3 g of vinyl acetate in 4 g of methanol was purged with nitrogen for 30 minutes, then polymerized in a water bath at 50° C. for 5 hours to obtain a copolymer of N-vinylformamide and vinyl acetate. Then add a methanol solution containing 0.2mol / L NaOH to the copolymer, and alcoholyze at 45°C for 30 minutes; dissolve the obtained solid in water, prepare a 10% aqueous solution, add 2mol / L HCl, and hydrolyze at 60°C After 80 minutes, vinylamine-vinyl alcohol copolymer hydrochloride was obtained; after ethanol precipitation, anion exchange and other impurity removal and purification processes, it was prepared into a polymer solution with a concentration of 1%. The solution was coated on the surface layer of a polysulfone ultrafiltration membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com