High film-formation cation grafted high-performance starch

A film-forming, cationic technology, applied in the textile industry, can solve the problems of high film-forming, anti-fatigue, insufficient high film-forming, restricting the application range of non-polyvinyl alcohol sizing, and achieve good film-forming performance , The effect of stable viscosity and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

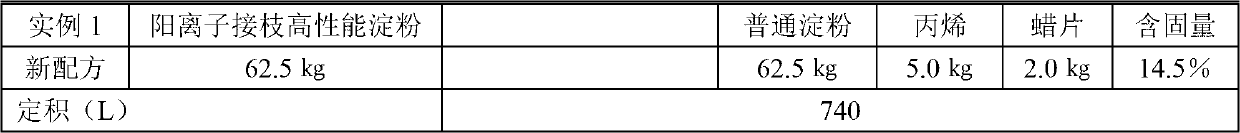

Embodiment 1

[0018] Put 83kg of corn starch, 6kg of 3-chloro-2-hydroxypropyltrimethylammonium chloride, 6kg of melamine hydrochloride, and 5kg of calcium persulfate into the reaction tank respectively, and dry mix them at 68°C After 45 minutes of etherification and grafting reaction, the reaction was terminated, and the materials were unloaded, packaged, and put into storage. When the customer is using it, add 800kg of clear water to gelatinize and heat up to 95°C or add clear water in a high-pressure tank to heat up to 125°C and keep it warm for 30-45min to carry out etherification and oxidation compound reactions to prepare the emulsion for fabric sizing.

[0019] After the slurry adhesion test, the pure cotton adhesion is 108N, and the polyester-cotton adhesion is 149N. Carry out the same adhesion test to the slurry prepared in Example 1 in CN102733190A, CN102733191A, and CN102605618A respectively, wherein CN102733190A pure cotton adhesion is 91N, polyester cotton adhesion is 115N; CN10...

Embodiment 2

[0022] Put 85kg of cornstarch, 6kg of 3-chloro-2-hydroxypropyltrimethylammonium chloride, 4kg of melamine hydrochloride, and 5kg of potassium hydrogen persulfate into the reaction tank respectively, and carry out the dry process at 68°C After 45 minutes of mixed etherification and grafting reaction, the reaction was terminated, unloaded, packaged, and put into storage. When the customer is using it, add 700kg of water to gelatinize and heat up to 95°C or add water in a high-pressure tank to heat up to 125°C and keep it warm for 30-45min to carry out etherification and oxidation compound reactions to obtain a fabric sizing emulsion. After the slurry adhesion test, the pure cotton adhesion is 108N, and the polyester-cotton adhesion is 148N. Its biodegradation test grade 9. The toughness and wear resistance tests were carried out on the serous film obtained by compounding this product with the auxiliary material of test 1. The wear resistance of this product is 1.29g / m 2 .

Embodiment 3

[0024] Put 90kg of cornstarch, 4kg of 3-chloro-2-hydroxypropyltrimethylammonium chloride, 3kg of melamine hydrochloride, and 3kg of ammonium persulfate into the reaction tank respectively, and carry out a compound mixing reaction at a temperature of 68°C After 45 minutes, the reaction was terminated, and the material was unloaded, packaged, and put into storage. When the customer is using it, add 680kg of water to gelatinize and heat up to 95°C or add water in a high-pressure tank to heat up to 125°C and keep it warm for 30-45min to carry out etherification and oxidation compound reactions to obtain fabric sizing emulsion. After the slurry adhesion test, the pure cotton adhesion is 111N, and the polyester-cotton adhesion is 158N. Its biodegradation test grade 9. The toughness and wear resistance tests were carried out on the serous film obtained by compounding this product with the auxiliary material of test 1. The wear resistance of this product was 1.31mg / cm 2 .

[0025] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com