TiO2@Ag/PVC (Poly Vinyl Chloride) composite antibacterial film and preparation method thereof

A PVC resin and film technology, applied in the direction of titanium oxide/hydroxide, rayon chemical post-treatment, fiber chemical characteristics, etc., can solve the problems of antibacterial performance, high production finished product, low material stability, etc., to achieve high efficiency antibacterial Bacterial performance, low production cost, broad-spectrum and long-lasting bactericidal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] TiO of the present invention 2 The preparation method of Ag / PVC composite bacteriostatic plastic film, concrete steps are as follows:

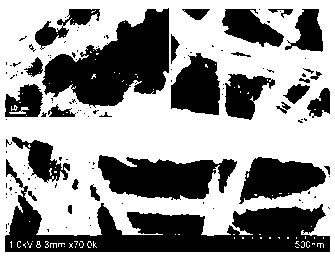

[0018] 1. Synthesis of TiO 2 Nanofibers

[0019] Add 1.0-1.5g of titanium dioxide powder (Degussa P25) and 120ml of 8-12 mol / L KOH aqueous solution into a high-pressure reactor equipped with a polytetrafluoroethylene liner. Between 140 and 170 o C for 30-40 hours, cooled naturally to room temperature, collected the white precipitate, washed with distilled water until neutral, and obtained hydrogen titanate nanofibers. o TiO can be obtained after high temperature sintering at C for 1~3h 2 Nanofibers.

[0020] 2. Synthesis of TiO 2 Ag nanocomposite fiber

[0021] Weigh 0.5~0.7gTiO 2 Nanofibers dispersed in 100 mL of water, at 65-75 o Add it into 100mL of silver ammonia solution with a concentration of 0.15-0.3 mol / L under the condition of C, stir for 1h, then add 50mL with a concentration of 3.0×10 -4 ~8.0×10 -4 mol / L aqueous ...

Embodiment 1

[0031]Weigh 1.2g of titanium dioxide powder and dissolve it in 120mL of KOH aqueous solution with a concentration of 10mol / L, at 150 o Centrifuge after reacting for 30 hours at C, wash it with clear water, and then add it to 100 mL of silver nitrate solution with a concentration of 0.2 mol / L, 70 o C under magnetic stirring for 1h, then add 50mL concentration of 5.0×10 -4 mol / L PVP solution maintained at 70 o C continued to react for 8h, and the product obtained TiO after centrifugal washing 2 Ag nanofibers.

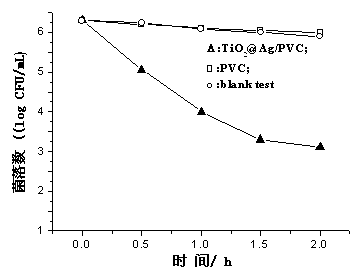

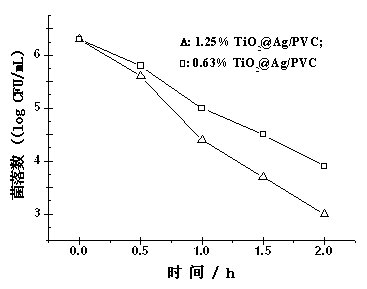

[0032] Then, weigh 0.5g of the obtained TiO 2 Ag nanofibers were dissolved in 100mL of γ-(2,3-glycidoxy)propyltrimethoxysilane (KH-560) toluene solution with a concentration of 0.1mol / L, and the modified TiO was obtained after reflux for 30min. 2 Ag nanofibers. Weigh the modified TiO according to the mass ratio of 1:47:30:0.32:1.6 2 Ag nanofiber, polyvinyl chloride resin, synthetic vegetable ester, calcium stearate and barium-zinc composite stabilizer, mixed evenly...

Embodiment 2

[0041] According to the method described in Example 1, TiO2Ag / PVC composite antibacterial film is prepared, and the modified TiO 2 The mass ratio of Ag nanofibers, polyvinyl chloride resin, bis(2-ethylhexyl) phthalate, glyceryl stearate and calcium-zinc composite stabilizer was adjusted to 1:15:9:0.12:0.53, Other conditions remain unchanged, modified TiO 2 Ag composite nanofibers occupy TiO 2 The mass fraction of the Ag / PVC composite antibacterial film is 3.9%, and the pH value is 8.0 under light conditions. 2 The antibacterial rate of Ag / PVC composite antibacterial film is 98.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com