Method for synchronously synthesizing transition metal nitride/graphitized carbon through ion exchange resin

An ion exchange resin, transition metal technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as increased cost, complicated process, restricted development and application, etc., and achieves convenient operation. , broad application value, and the effect of commercialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

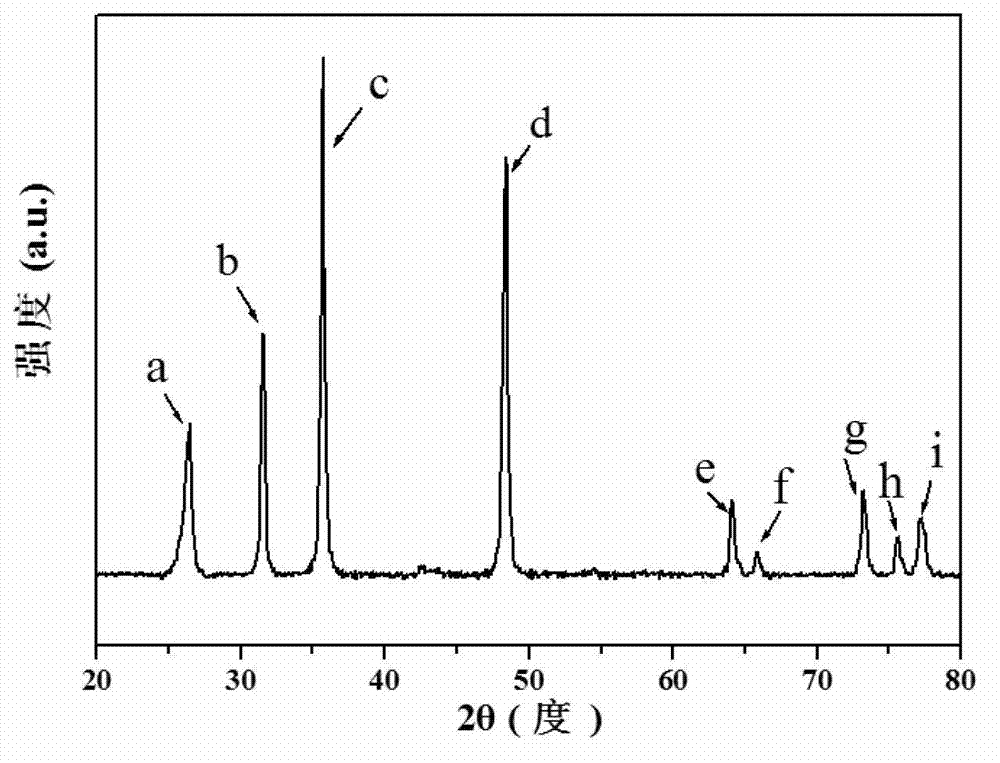

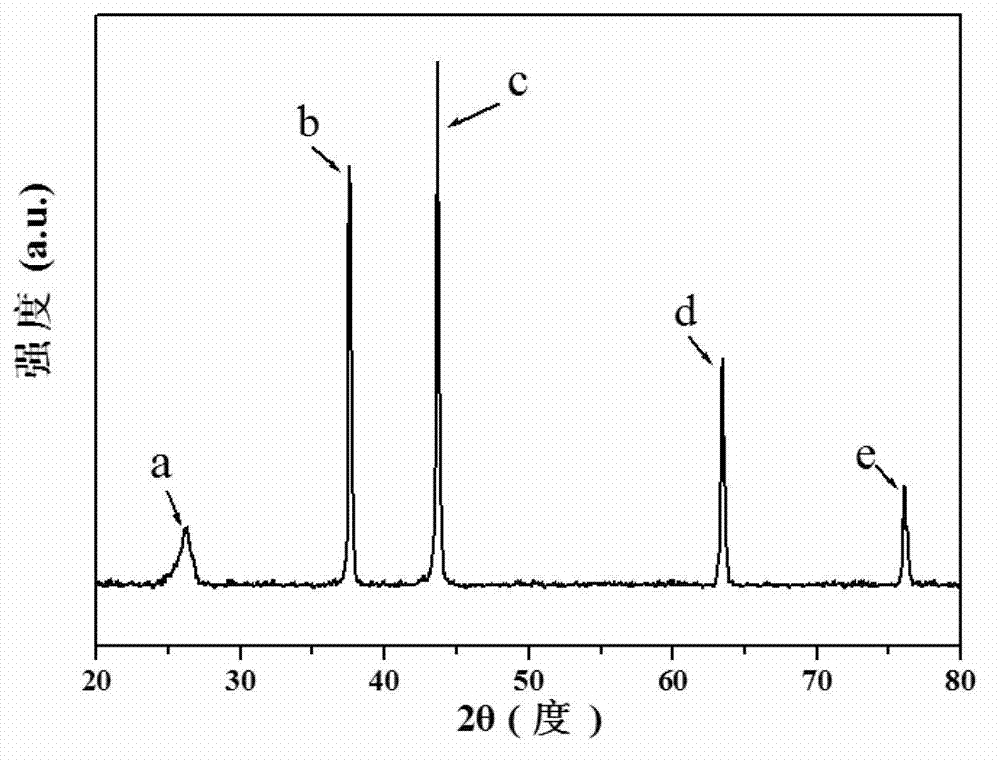

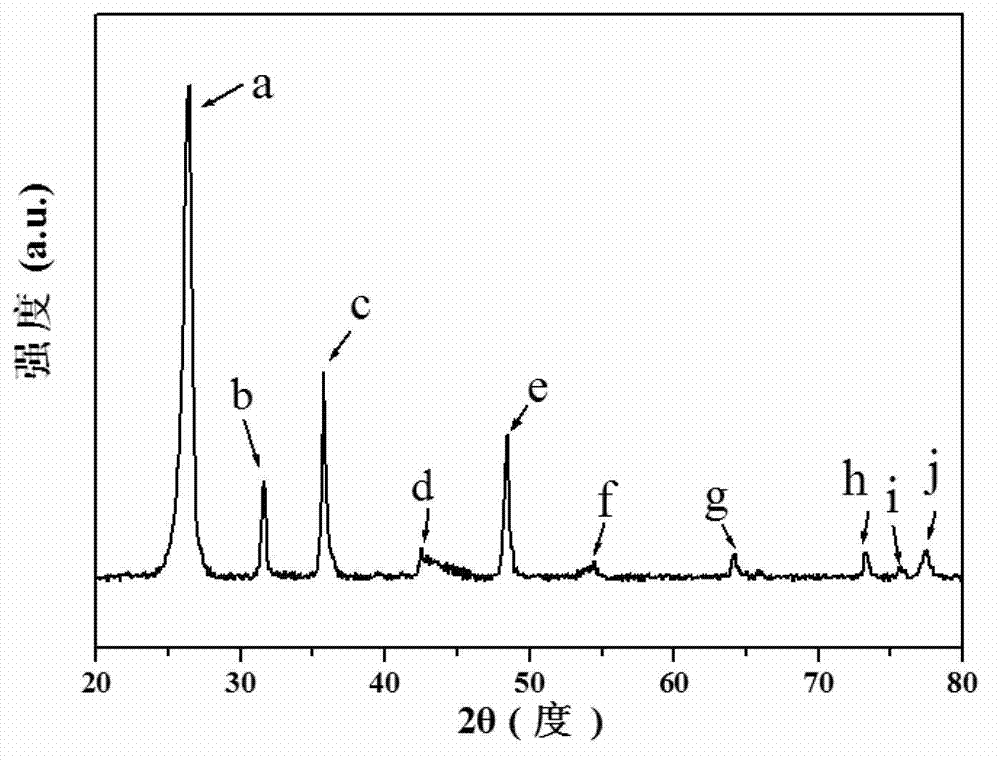

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: the present embodiment utilizes the method for synchronous synthesis transition metal nitride / graphitized carbon of ion exchange resin, is to carry out according to the following steps: one, adopt acid treatment method or alkali treatment method to carry out pretreatment to carbon source 2~ 8h, obtain the pretreated carbon source; 2. Dissolve the graphitization catalyst with a concentration of 0.01 to 0.3mol / L and the transition metal salts with a concentration of 0.01 to 0.3mol / L in a solvent, and then add the pretreated Carbon source, stir 2~24h, obtain mixture; Wherein the mass ratio of the carbon source of pretreatment and graphitization catalyst is (1~10): 1, the mass ratio of the carbon source of pretreatment and transition metal salts is ( 1~10): 1; 3. Under air or oxygen atmosphere, pre-carbonize the mixture of step 2 for 2-5 hours at 350° C. to obtain a pre-carbonized mixture; 4. At a heating rate of 5-20° C. / min, Raise the temperature ...

specific Embodiment approach 2

[0016] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the specific operation steps of the acid treatment method in step one are: the carbon source is added to the nitric acid solution with a mass fraction of 10% to 20%, at 80% to 20% Reflux at 150°C for 4-8 hours to complete the acid treatment, wherein the mass-volume ratio of carbon source to nitric acid solution is 10g:50mL. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0017] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the specific operation steps of the alkali treatment method in step one are as follows: the carbon source is added into a potassium hydroxide solution with a mass fraction of 10% to 20% and ultrasonically Stir for 4 to 7 hours, wash with distilled water until the pH is 7, and then dry at 80°C to 100°C for 6 to 8 hours to complete the alkali treatment, wherein the mass volume ratio of carbon source to KOH solution is 10g:50mL. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com