Method for preparing lanthanum aluminate powder efficiently

A technology of lanthanum aluminate and powder is applied in the field of efficient preparation of lanthanum aluminate powder, which can solve the problems of large raw material particle size, reduced material particle size, long synthesis time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

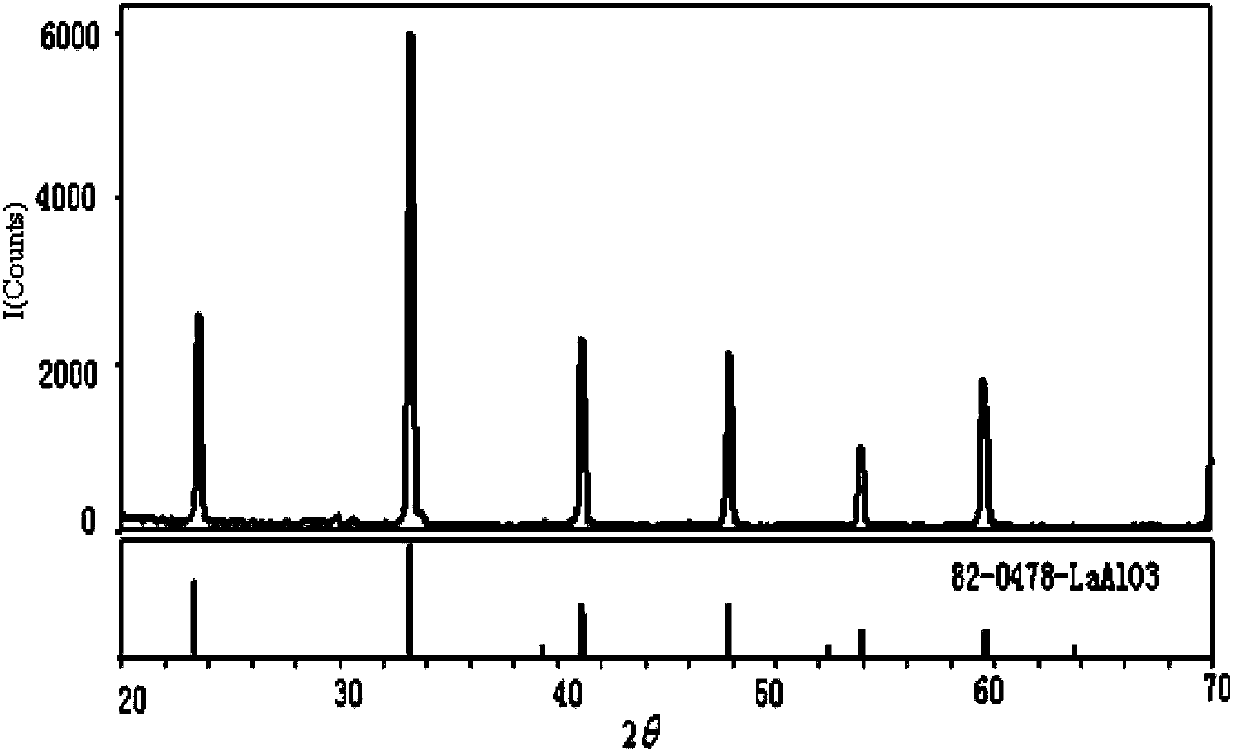

Image

Examples

Embodiment 1

[0023] Example 1. Lanthanum oxide and aluminum hydroxide were used as initial raw materials. The purity of lanthanum oxide was 99.9% (mass percentage), and aluminum hydroxide was an analytically pure chemical reagent (including 33.0% moisture). Weigh 32.60g-0.10mol of lanthanum oxide on a balance, add 200g of water, and hydrothermally heat it in a constant temperature water bath at 100°C for 2.0 hours. The lanthanum oxide is converted to La(OH) by hydrothermal method. 3 . The balance weighs 23.28 g of aluminum hydroxide (including Al(OH) 3 0.20mol), La(OH) 3 And Al(OH) 3 Mix with water as a medium and stir for 2 minutes, then filter. The filtered mixture is calcined at a high temperature of 1100°C for 2.0 hours.

Embodiment 2

[0024] Example 2. Lanthanum oxide and aluminum hydroxide were used as initial raw materials. The purity of lanthanum oxide was 99.9% (mass percentage), and aluminum hydroxide was an analytically pure chemical reagent (including 33.0% moisture). Weigh 48.90g-0.15mol lanthanum oxide with a balance, add 300g of water, and hydrothermally heat it in a constant temperature water bath at 100°C for 3 hours. The lanthanum oxide is converted to La(OH) by hydrothermal method. 3 . The balance weighs 34.93 g of aluminum hydroxide (including Al(OH) 3 0.30mol), La(OH) 3 And Al(OH) 3 Use water as the medium to mix and stir for 3 minutes, then filter. The filtered mixture is calcined at a high temperature of 1100°C for 2.5 hours.

Embodiment 3

[0025] Example 3. Lanthanum oxide and aluminum hydroxide were used as initial raw materials. The purity of lanthanum oxide was 99.9% (mass percentage), and aluminum hydroxide was an analytically pure chemical reagent (including 33.0% moisture). Weigh 65.20g-0.20mol of lanthanum oxide with a balance, add 350g of water, and hydrothermally heat it in a constant temperature water bath at 95°C for 4.0 hours. The lanthanum oxide is converted to La(OH) by hydrothermal method. 3 . The balance weighs 46.57 g of aluminum hydroxide (including Al(OH) 3 0.40mol), La(OH) 3 And Al(OH) 3 Mix with water as a medium and stir for 4 minutes, then filter. The filtered mixture is calcined at a high temperature of 1150°C for 2.5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com