Fiber surface modification method capable of adaptively constructing interaction for base bodies with different properties and application thereof

A fiber surface, self-adaptive technology, used in carbon fiber, fiber processing, textiles and papermaking, etc., can solve problems such as drop, fiber damage performance, etc., to increase specific surface area, enhance mechanical lock and function, and enhance the effect of interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

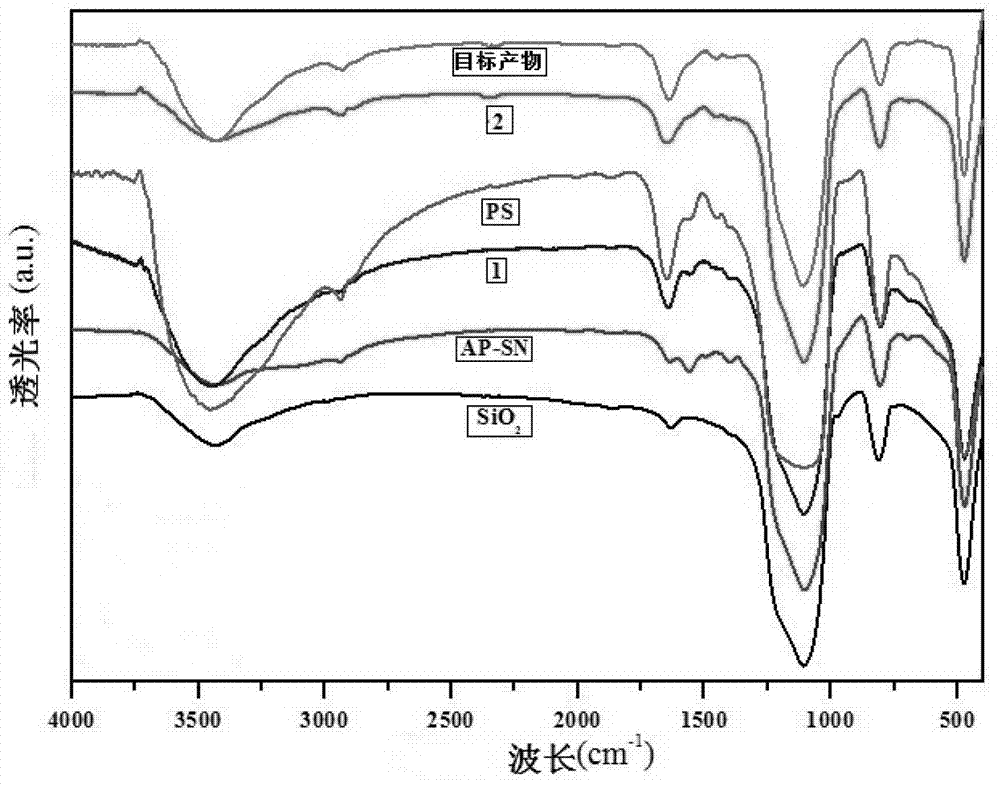

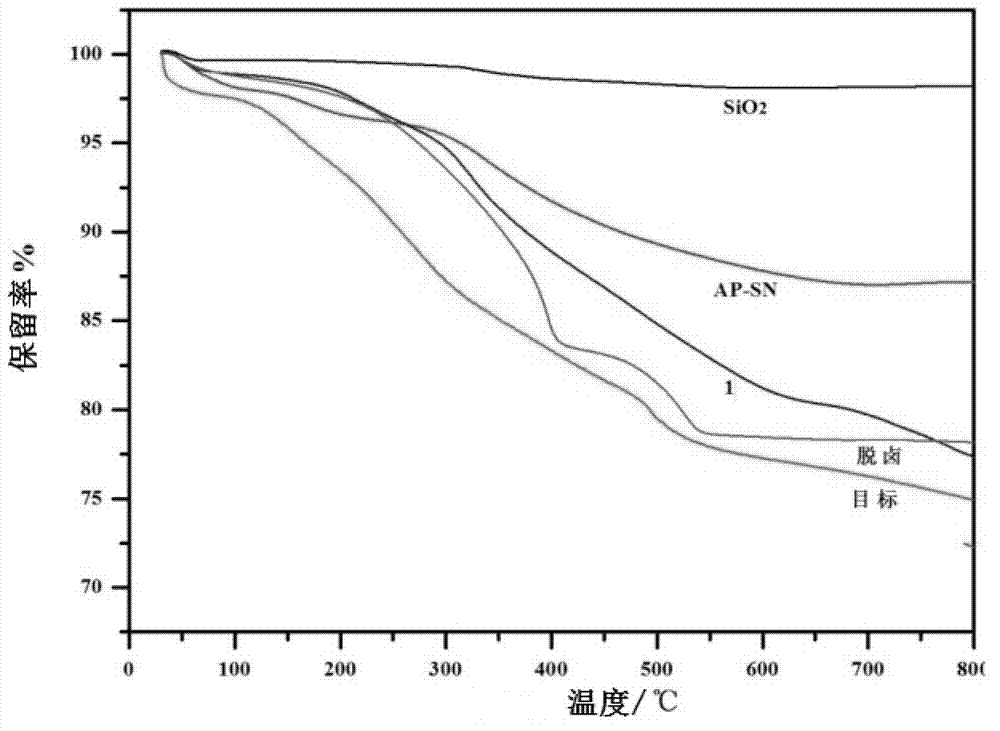

[0067] 1 nm SiO 2 Synthesis of hybrid particles

[0068] 1) Synthesis of AP-SN

[0069] in N 2 Under the atmosphere, 5g of nano-SiO 2 Add to a 500ml three-necked round-bottomed flask filled with anhydrous toluene, stir to form a suspension, and when the system temperature reaches the toluene reflux temperature (110°C), add a mixed solution of 10.5ml of APTES and 10ml of anhydrous toluene dropwise, and stir to reflux After 24 hours, cool, centrifuge, wash three times with absolute ethanol, dry under vacuum at 40°C, and record it as AP-SN.

[0070]2) synthesis of macroinitiator 1 (reaction 40%-NH 2 )

[0071] in N 2 Under the atmosphere, add 4g of AP-SN and 0.2232ml of triethylamine into a three-necked round-bottomed flask filled with 250ml of anhydrous toluene respectively, ice bath and stir for 15min, until the temperature of the system drops to 0°C, dropwise Add a mixed solution of 0.1392ml bromoacetyl bromide and 10ml anhydrous toluene, react at room temperature for 1...

Embodiment 2

[0103] 1 nm SiO 2 Synthesis of hybrid particles

[0104] 1) Synthesis of AP-SN

[0105] APTES is the APTES of 15.85ml, and other is with embodiment 1.

[0106]2) Synthesis of macroinitiator 1 (reaction 40%-NH 2 )

[0107] AP-SN is 4g, triethylamine 0.311ml, bromoacetyl bromide 0.194ml, and others are the same as in Example 1.

[0108] 3) Initiate the ATRP reaction of St

[0109] The macroinitiator 1 of 4g, PMDETA0.465ml, CuBr0.319g, St5.838ml, other are the same as embodiment 1.

[0110] 4) PS-Br dehalogenation

[0111] PS-Br3g, PMDETA0.175ml, CuBr0.121g, TBH1.347ml, other with embodiment 1.

[0112] 5) Synthesis of macroinitiator 2 (reaction 60%-NH 2 )

[0113] 3 g of the dehalogenated product, 0.351 ml of triethylamine, 0.229 ml of bromoacetyl bromide, and the others are the same as in Example 1.

[0114] 6) Initiate the ATRP reaction of HEA

[0115] 3g macroinitiator 2, PMDETA0.523ml, CuBr0.358g, HEA6.589ml, others are the same as embodiment 1.

[0116] 2nm SiO ...

Embodiment 3

[0121] 1 nm SiO 2 Synthesis of hybrid particles

[0122] 1) Synthesis of AP-SN

[0123] APTES is the APTES of 26.45ml, and other is with embodiment 1.

[0124] 2) Synthesis of macroinitiator 1 (reaction 40%-NH 2 )

[0125] AP-SN is 4g, triethylamine 0.379ml, bromoacetyl bromide 0.237ml, and others are the same as in Example 1.

[0126] 3) Initiate the ATRP reaction of St

[0127] The macroinitiator 1 of 4g, PMDETA0.568ml, CuBr0.391g, St7.140ml, other are the same as embodiment 1.

[0128] 4) PS-Br dehalogenation

[0129] PS-Br3g, PMDETA0.214ml, CuBr0.148g, TBH1.647ml, other with embodiment 1.

[0130] 5) Synthesis of macroinitiator 2 (reaction 60%-NH 2 )

[0131] 3 g of the dehalogenated product, 0.428 ml of triethylamine, 0.281 ml of bromoacetyl bromide, and others are the same as in Example 1.

[0132] 6) Initiate the ATRP reaction of HEA

[0133] 3g macroinitiator 2, PMDETA0.639ml, CuBr0.439g, HEA8.058ml, others are the same as embodiment 1.

[0134] 2nm SiO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com