Method for preparing hierarchical pore molecular sieve materials

A molecular sieve, multi-level pore technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of unfavorable free diffusion of macromolecules, complicated process, weak interaction between cationic surfactant and molecular sieve precursor, etc. and purification, good hydrothermal stability and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

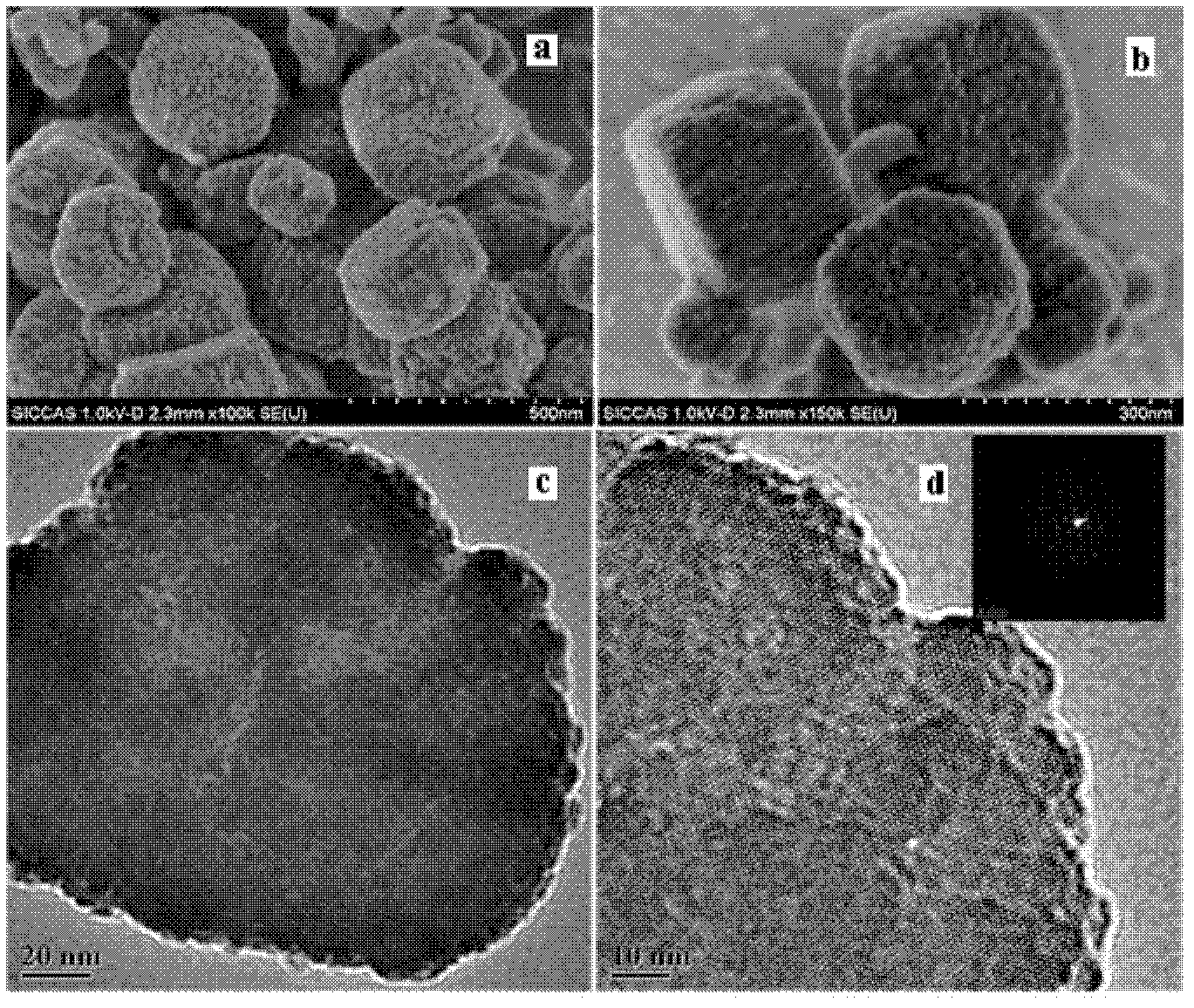

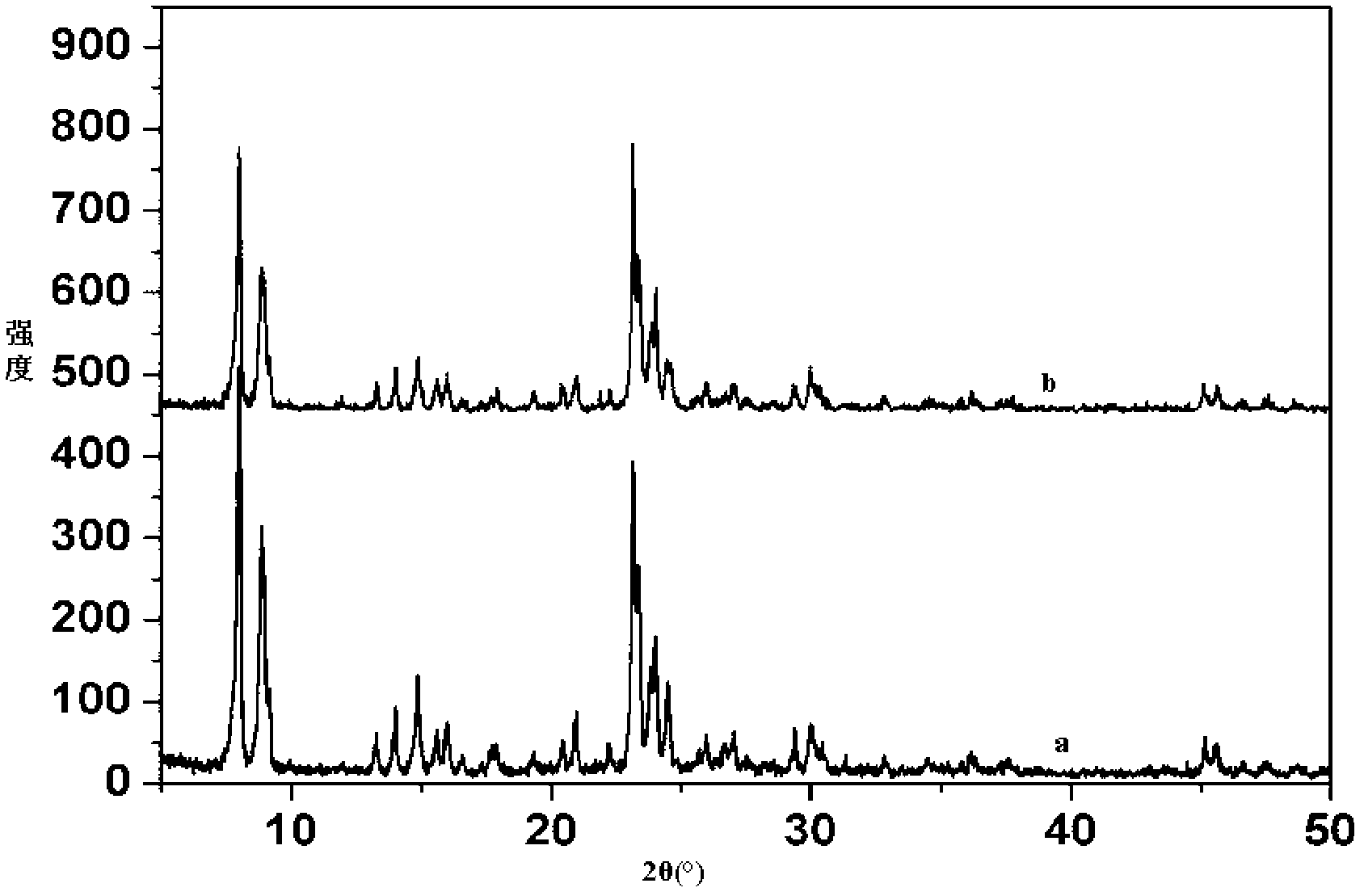

Embodiment 1

[0031] a) Preparation of reaction precursor solution: add 0.31g of aluminum isopropoxide and 15.62g of ethyl silicate to 26g of water, stir at room temperature for 2h, then dropwise add 21.96g of 25wt% tetrapropylammonium hydroxide, and stir at 40°C to clarification;

[0032] b) Aging to prepare high polymer sub-grains: continue stirring the solution obtained in step a) in an oil bath at 100°C for 2 days;

[0033] c) Preparation of hierarchically porous molecular sieve material: After the high poly subgrain solution obtained in step b) is cooled to room temperature, it is slowly added dropwise to an aqueous solution of cationic surfactant CTAB (0.765g CTAB is dissolved in 90ml of water), at 80°C Stir for 2 hours, then add 12g of ethanol, continue to stir for 2 hours to make the mixture uniform, and then carry out hydrothermal crystallization in a 150°C hydrothermal kettle for 24 hours;

[0034] d) Suction filtration, washing, drying in an oven at 100°C under normal pressure f...

Embodiment 2

[0038] The difference between this example and Example 1 is that the aqueous solution of the cationic surfactant CTAB used is prepared by dissolving 0.3825g CTAB in 90ml water.

[0039] All the other contents are the same as those described in Example 1.

[0040] The structural parameter data of the prepared hierarchical porous molecular sieve material are shown in Table 1.

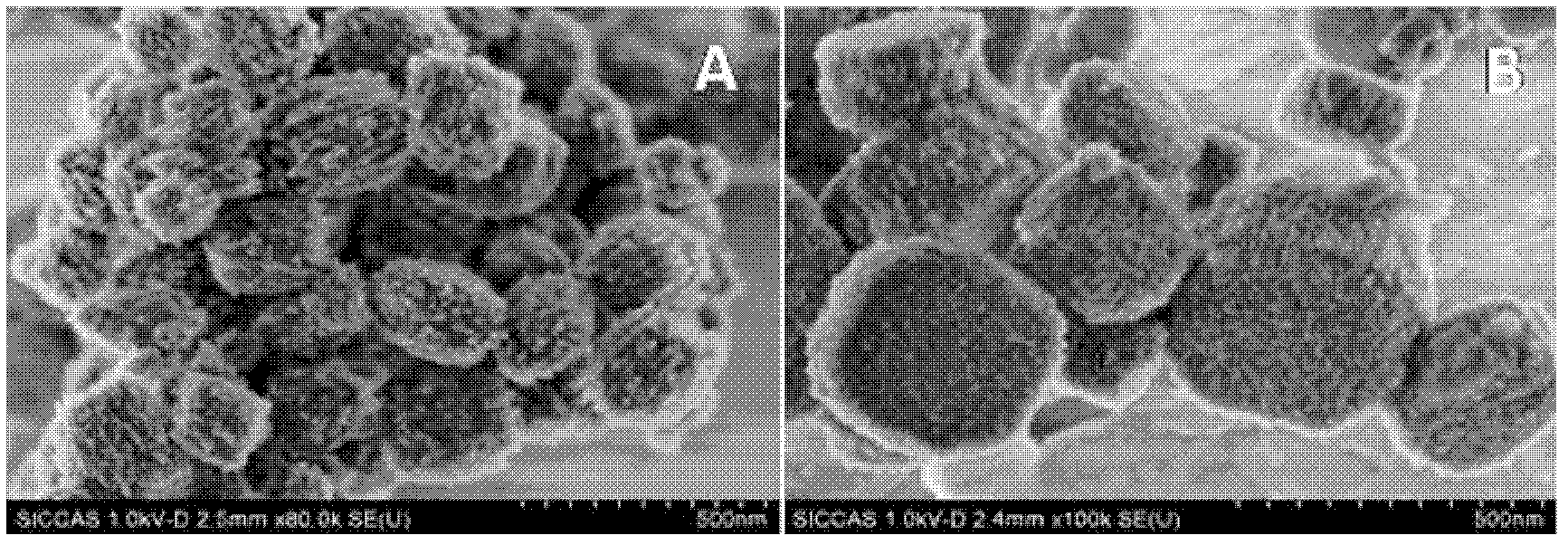

[0041] The SEM photo of the prepared hierarchical porous molecular sieve material is shown in image 3 Shown in Figure A.

Embodiment 3

[0043] The difference between this example and Example 1 is that the aqueous solution of the cationic surfactant CTAB used is prepared by dissolving 0.576g of CTAB in 90ml of water.

[0044] All the other contents are the same as those described in Example 1.

[0045] The structural parameter data of the prepared hierarchical porous molecular sieve material are shown in Table 1.

[0046] The SEM photo of the prepared hierarchical porous molecular sieve material is shown in image 3 Shown in Figure B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com