Treatment of diabetes mellitus by taking insulin PEGylation derivative as active component

A cathodic arc ion plating and temperature control device technology, which is applied in ion implantation plating, coating, metal material coating process, etc., can solve the problems of industrial application limitations, large residual stress value, low bonding strength, etc., and achieve durability Abrasive anti-adhesion, high toughness, effect of improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

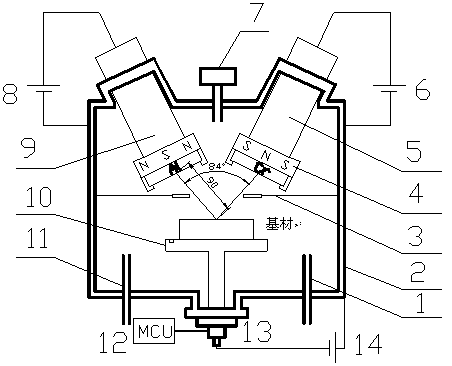

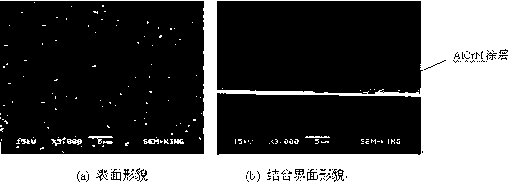

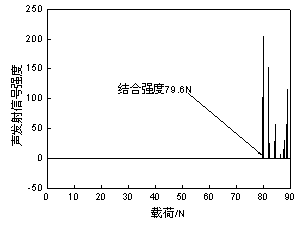

[0014] The specific method of preparing AlCrN coating is described below in conjunction with the picture:

[0015] (1) Polish the surface of the substrate, and then ultrasonically clean it in acetone and alcohol for 15 minutes; install the substrate on the workbench 10, the size of the substrate is 100×100mm, adjust the height of the workbench 10 to ensure the center of the substrate and the target The distance between the materials is 90mm.

[0016] (2) Use the vacuum pump 7 to control the pressure in the deposition chamber 2 to 1.3×10 -3 Within Pa, place a partition between the substrate and the target, drive the servo motor 13 to make the table 10 rotate at a speed of 5 rpm, and feed pure argon (Ar, purity 99.99%) to control the flow rate of 50 sccm to maintain the pressure of the deposition chamber 2 at 0.5 Pa , the bias power supply 14 is set to 200V, and the substrate is cleaned by plasma for 10 minutes.

[0017] (3) During the cathode ion plating process, N is passed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com