Preparation method of modified palladium metal catalyst, prepared catalyst and application thereof

A metal catalyst and modification technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problem of low catalytic activity, small catalytic active area, palladium metal Particle distribution and other issues, to achieve strong catalytic activity, increase catalytic active area, and strong anti-carbon monoxide poisoning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 prepares modified palladium metal catalyst

[0025] The preparation method of the present embodiment modified palladium metal catalyst comprises the following steps:

[0026] The first step is to prepare the titanium dioxide dispersion: firstly grind the titanium dioxide powder evenly and then calcinate it for the first time, then add nitric acid solution to the powder calcined for the first time until the powder is wet, and then calcinate it for the second time after drying; then, the second time The secondary calcined powder is ground evenly and added with hydrofluoric acid solution, stirred and filtered to obtain a solid, and the solid is washed with water until the washing liquid is neutral and dried to obtain a powder; then, deionized water is added to the dried powder to obtain a solid-liquid ratio It is 5-10 g / L titanium dioxide dispersion.

[0027] Wherein, the titanium dioxide powder with a particle size of 20-80 nanometers, the nitric acid soluti...

Embodiment 2

[0043] Transmission electron microscope test and X-ray diffraction test of embodiment 2 modified palladium metal catalysts

[0044] The modified palladium metal catalysts prepared in each case of Example 1 were tested by transmission electron microscopy and X-ray diffraction using existing conventional methods.

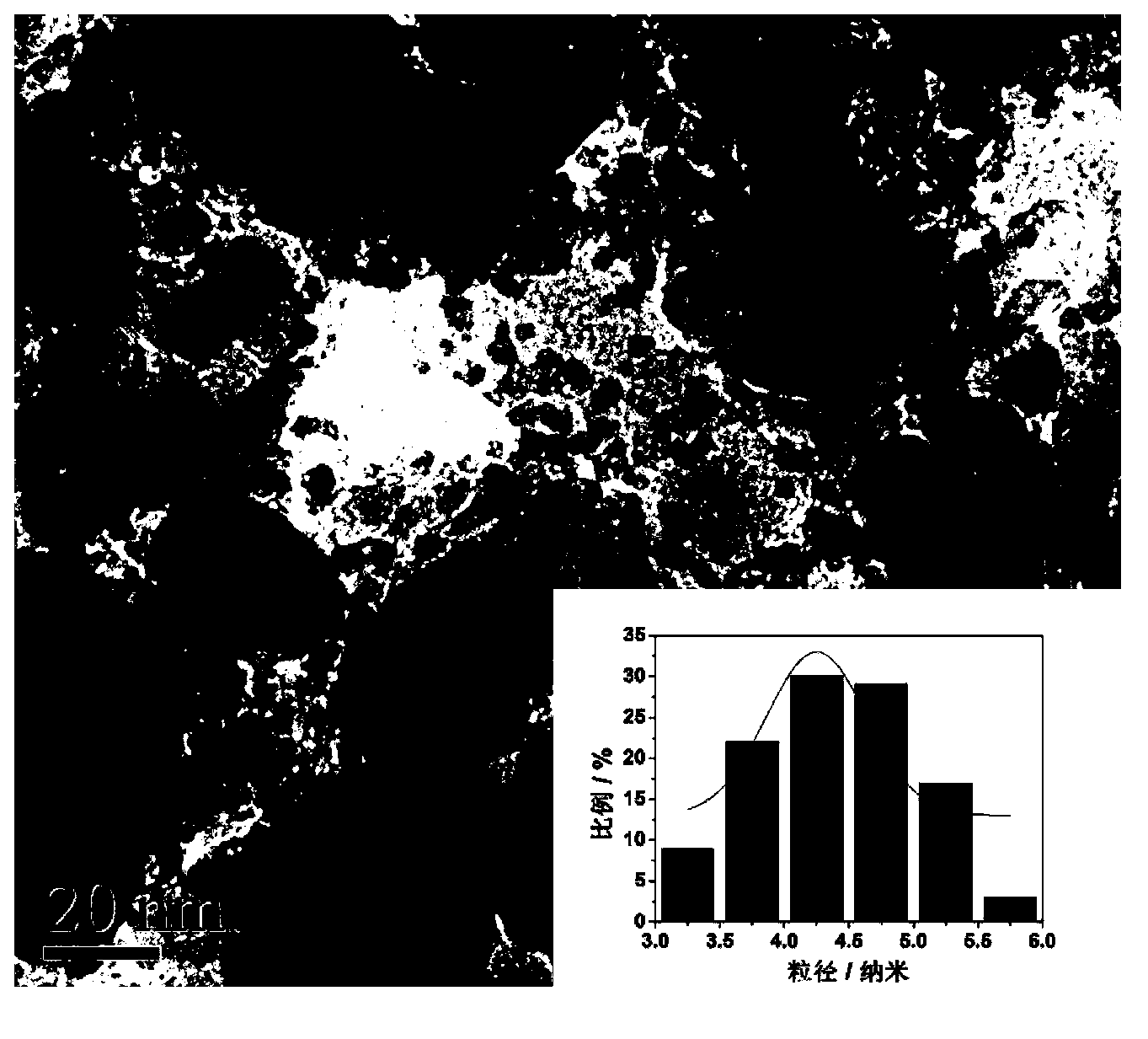

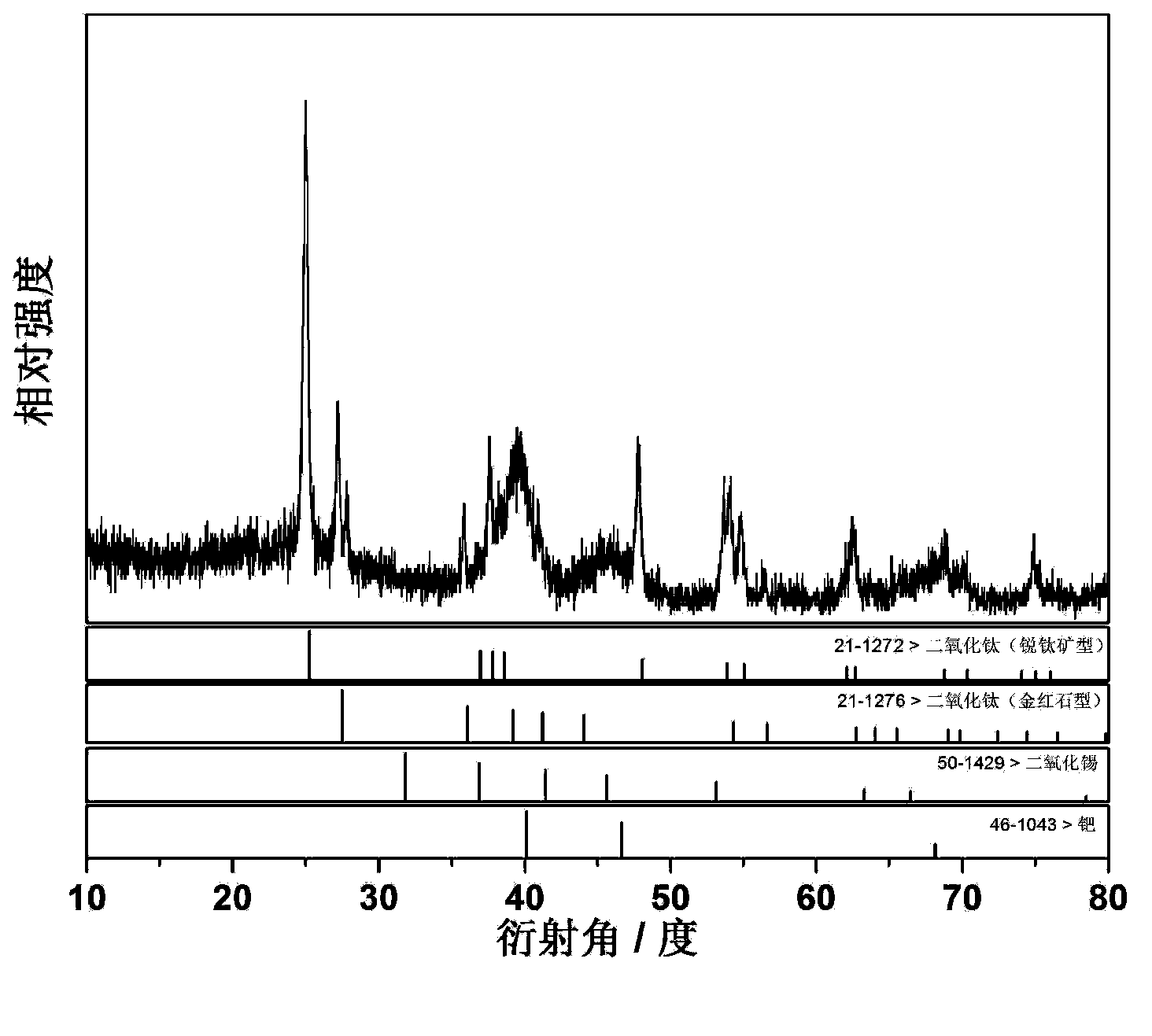

[0045] The results show that the test results of each case are basically the same. Among them, the transmission electron microscope picture and its particle size distribution picture are as follows figure 1 As shown, the data shows that in the catalyst prepared in Example 1, the particle diameter of the palladium metal particles is mainly 3.5-5.0 nanometers, and the average particle diameter is 4.5 nanometers; this result shows that the palladium metal particles distributed on the surface of the carrier are evenly distributed. X-ray diffraction pattern as figure 2 As shown, it shows that the precursor-supported palladium metal catalyst was successfully prepared on ...

Embodiment 3

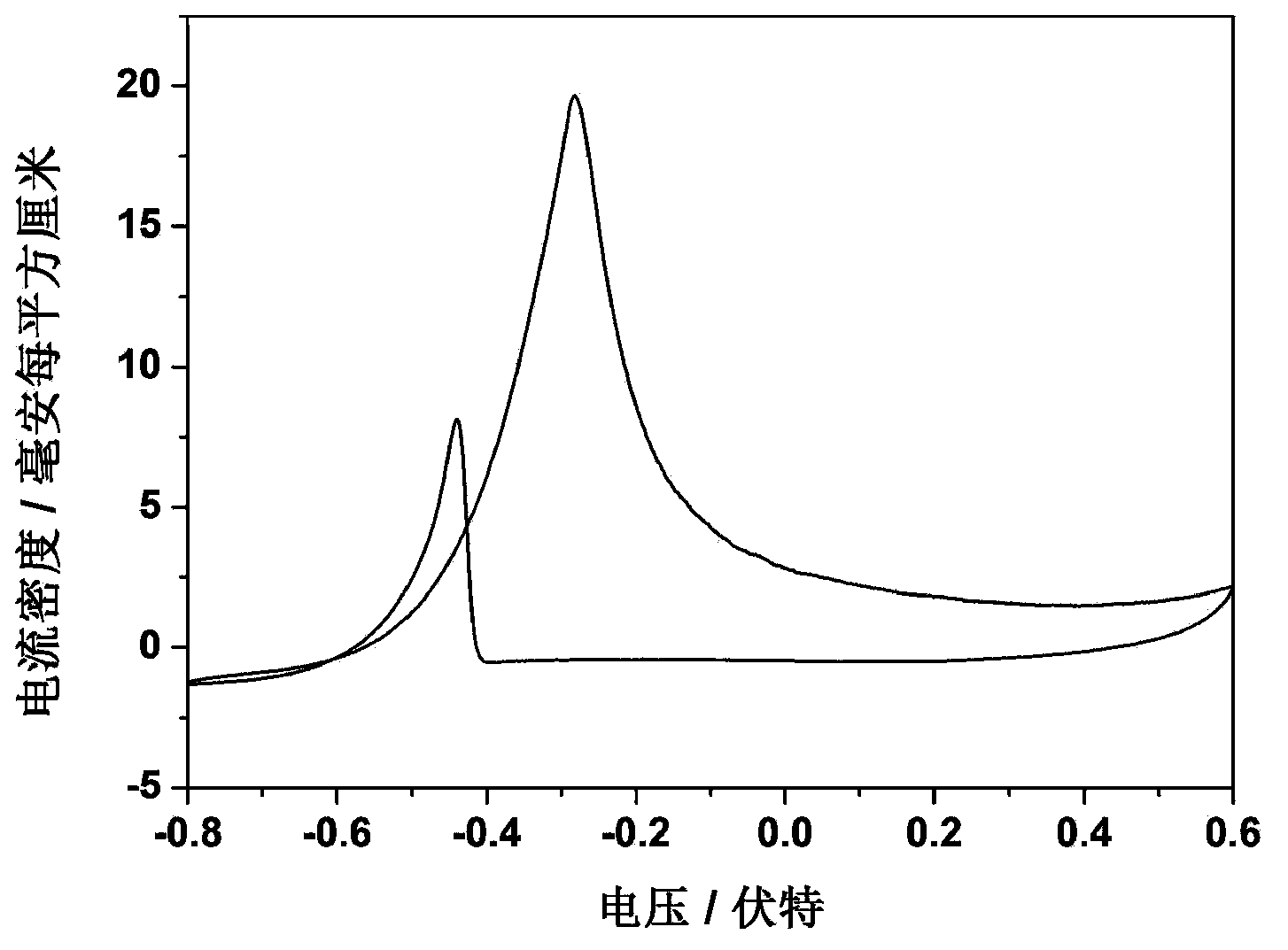

[0046] Embodiment 3 Modified palladium metal catalyst to the oxidation electrocatalytic performance detection of alkaline system ethanol

[0047] The detection experiment adopts a three-electrode system, wherein, the catalyst prepared in Example 1 is used as the working electrode, the platinum plate electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode, and Chenhua CHI660D electrochemical workstation is used as the detection experimental workstation. The volume of alkaline ethanol electrolyte (0.25mol / L ethanol + 0.25mol / L potassium hydroxide solution) is 10 ml, and the catalytic activity of the catalyst is investigated by cyclic voltammetry (the scan rate is 50 mV / s, and the scan potential range -0.8~0.6 volts).

[0048] The result is as image 3 As shown, wherein, the positive sweep peak current value is 19.6 mA / cm2, and the reverse sweep peak current value is 8.1 mA / cm2. Show that the catalyst prepared in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com