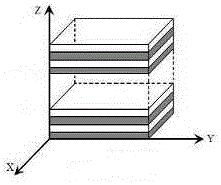

Multi-layer composite environmental protection flame retardant sound insulation coiled material products

A multi-layer composite, environmentally friendly technology, applied in the fields of new flame retardant materials and preparation, and sound insulation, can solve the problems of complex oxide treatment on the surface of metal powder, environmental protection performance to be further improved, screw wear of extrusion equipment, etc. Low, tough, reducing the effect of overall density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Granulation:

[0042] Material A: Stir 50Kg PVC and 12.5Kg environmentally friendly plasticizer at a temperature of 70-90°C for 2 minutes at high speed, then mix 25Kg barium sulfate, 5.25Kg magnesium hydroxide-hydroxide-zinc-aluminum borate compound (among which magnesium hydroxide: The weight ratio of aluminum hydroxide: zinc borate is 1:1:2), calcium zinc stabilizer 1.6Kg, titanium dioxide 3.2Kg lubricant 0.1Kg, antioxidant 0.1Kg were added to it, high speed stirring to 110-120 ℃ , discharging, the above powder is granulated through a twin-screw extruder, the temperature of the screw barrel is 150-190°C (preferably 150-155°C), the die temperature is 150-200°C (preferably 150°C ).

[0043] Material B: Stir 50Kg PVC and 22.5Kg environmentally friendly plasticizer at 70-90°C (preferably 70°C) for 2 minutes at high speed, then mix 22.5Kg barium sulfate, 5Kg calcium carbonate, 5.25Kg magnesium hydroxide-hydrogen Aluminum oxide-zinc borate composite (the weight ratio o...

Embodiment 2

[0048] 1. Granulation:

[0049] Material A: Stir 25Kg PVC and 2.5Kg environmentally friendly plasticizer at 70-90°C for 2 minutes at high speed, then mix 6.25Kg barium sulfate, 0.75Kg magnesium hydroxide-aluminum hydroxide-zinc borate compound (including magnesium hydroxide : aluminum hydroxide: zinc borate weight ratio is 1:2:3), calcium zinc stabilizer 1.1Kg, titanium dioxide 1.3Kg lubricant 0.03Kg, antioxidant 0.06Kg, processing aid 0.6Kg (a total of 12.36 Parts) were added to it respectively, stirred at high speed to 110-120°C, discharged, the above powder was granulated through a twin-screw extruder, the temperature of the screw barrel was 150-190°C (preferably 168°C), and the die The temperature is 150-200°C (preferably 168°C).

[0050] Material B: Stir 25Kg PVC and 5.0Kg environmentally friendly plasticizer at 70-90°C for 2 minutes at high speed, then mix 5.0Kg barium sulfate, 1.0Kg magnesium hydroxide-aluminum hydroxide-zinc borate compound, calcium zinc stabilizer 0...

Embodiment 3

[0055] 1. Granulation:

[0056] Material A: Stir 37.5Kg PVC and 8.5Kg environmentally friendly plasticizer at 70-90°C for 2 minutes at high speed, then mix 12.5Kg barium sulfate, 3Kg calcium carbonate, 2.5Kg magnesium hydroxide-aluminum hydroxide-zinc borate compound (The weight ratio of magnesium hydroxide: aluminum hydroxide is 1:1:2), calcium zinc stabilizer 2.8Kg, titanium dioxide 3.3Kg, lubricant 0.22Kg, antioxidant 0.07Kg were added to it, and stirred at high speed until 110-120°C, discharge, the above powder is granulated through a twin-screw extruder, the temperature of the screw barrel is 150-190°C (preferably 170°C), the die temperature is 150-200°C (preferably 175°C) ℃).

[0057] Material B: Stir 50Kg PVC and 15Kg environmentally friendly plasticizer at 70°C for 2 minutes at high speed, then mix 15Kg of barium sulfate, 4.0Kg of magnesium hydroxide-aluminum hydroxide-zinc borate compound, and 1.2Kg of calcium-zinc stabilizer. Add 1Kg of auxiliary agent, 1.5Kg of ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com